jaybug wrote:...Also, would any one know if the cylinders in the front drums are a little bigger than the rears?

If so I was thinking of changing them over, if its possible, to improve the rear braking also.

Although if the front works out I'll probably do the same in the back...

Yes, they're substantially larger - yet the offset of the `68-up rear wheel cylinder is the same as that of the front W/C, so they bolt right up and fit just fine. I recommend that you do that to bring the front-to-rear balance back into the normal realm; upgrading the rear linings to semi-metallics is also a good move.

It's a bit more involved converting the rears to disc, since there are no stock ACVW parts that can be used to accomplish it (914 Porsche is as close as it gets) so most folks forego the DIY route and buy an aftermarket setup. The cheap ones have no parking/emergency brake (which means they aren't street-legal) and you've got to look out for proprietary components which you may not be able to find replacements for in the future. Personally I like to use Porsche 924T/944 rears since they're easy to find. You have to make up your own hydraulic pipes and install aftermarket "swans" and extension tubes to couple the Bug parking brake cables to the Porsche brakes, but that's almost trivial - the bigger issue is that they're 5x130 (and not really redrillable) so you have to run Porsche rims with them.

Another solution, IMO as good as rear discs (except for the fact that you'll still need to adjust them now & then) is to use Type III rear brakes - they bolt right on, using the stock Bug plumbing and cables. Type III and IV rears are the same other than the center hubs of the drums; they'll cause a

slight increase in track width (like, ~¼") which is seldom a problem unless you have very tight sidewall-to-fender clearance.

VW's answer to the RPV question was to use "restriction drillings" in the M/C - they don't actually hold any residual pressure, but they do impede the rate at which fluid can suck back into the M/C on the pedal upstroke and that's usually enough to prevent air from being drawn in at the wheels cylinders/calipers. Since the `70s, the 113 611 015BD M/C has been the only replacement part available for Beetles/Ghias/Things, and it seems to work just fine in most drum, disc/drum, and even disc/disc installations...there is a larger-bore (non-stock) M/C available if you find that it's needed, but shouldn't be required if the calipers chosen aren't too large.

I'm not crazy about the idea of DIY caliper brackets, but if you're confident that you can handle making their attachment sufficiently robust go for it. Karmann-Ghia spindles that already have stout integral "wings" for caliper attachment are fairly easy to come by, though, so IMO they'd be a better way to go.

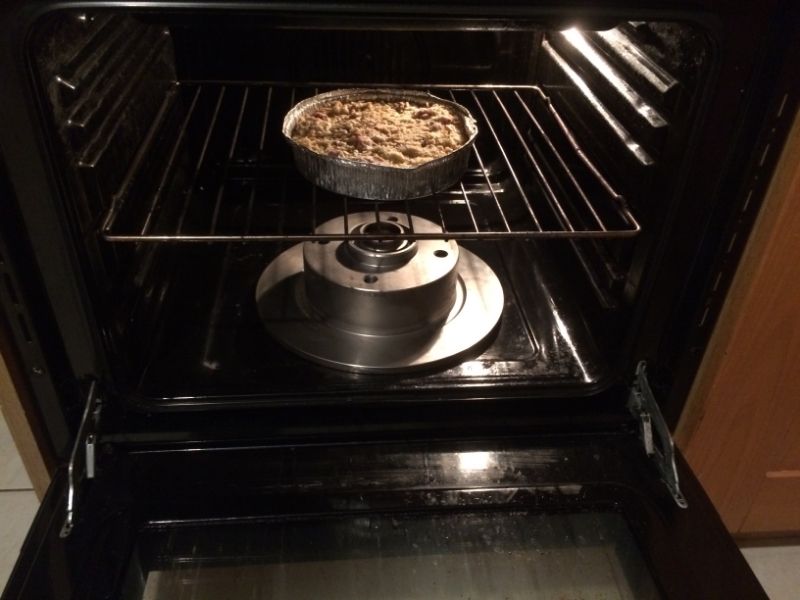

I see that you've got the late, hub-centric rotors - those don't fit on most wheels which were made for the earlier "bolt-centric" drums/discs so you'd better confirm that your wheels will bolt on before you go much further.