Bit odd at speed?

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

Finally an update, today booked out the 4 post ramp today at the car club on the base and set about replacing the torsion bushes and dropping it a spline. Took 5 hrs but was going slow and chatting and helping others etc...

The bushes looked pretty mashed and seemed wrong, inner bushes were the correct knobbed ones but the outers were the same, not smooth doughnuts that's replaced them with....

One torsion cover bolt sheered which I'll need to drill out soon and probably replace the covers in the new year as mine are a little crusty...

Made a load of pencil marks for reference, lubed the bushes with silicone grease on re assembly and used my pencil marks to clock it one outer spline lower. Put it back together and set the tracking so each one was equal distance fwd/back but not sure of the toe in/out yet as I was on the 4 post ramp not a drive on jobby, that's a job for this week coming.

First impressions... It's low and I like it!

I can fit 1 finger between the tyre and the wing. Instead of my fist and then some it was before.

Roads are damp and slimey but it feels good so far.

Helped by the new Bridgestone potenzas re002's in 195/60/15, nice sticky tyre!!

The bushes looked pretty mashed and seemed wrong, inner bushes were the correct knobbed ones but the outers were the same, not smooth doughnuts that's replaced them with....

One torsion cover bolt sheered which I'll need to drill out soon and probably replace the covers in the new year as mine are a little crusty...

Made a load of pencil marks for reference, lubed the bushes with silicone grease on re assembly and used my pencil marks to clock it one outer spline lower. Put it back together and set the tracking so each one was equal distance fwd/back but not sure of the toe in/out yet as I was on the 4 post ramp not a drive on jobby, that's a job for this week coming.

First impressions... It's low and I like it!

I can fit 1 finger between the tyre and the wing. Instead of my fist and then some it was before.

Roads are damp and slimey but it feels good so far.

Helped by the new Bridgestone potenzas re002's in 195/60/15, nice sticky tyre!!

-

buildabiggerboxer

- Posts: 621

- Joined: Wed Mar 25, 2009 12:50 pm

Re: Bit odd at speed?

That's a step forward then Andy, if you have any gap left between wing and tyre, get it spaced out right to the minimum clearance gap, depending how much spacer you can use, it will lower the rear some more and make it softer, good shox? Basic gas spax are very very good and good value, a little dearer are protech shocks, still one way adjust, but that's all you need, I've raced them via someone else's car and can only say they impressed me, then there's Gaz of course, have fun doing the tracking, measure it only at ride height, don't forget the Dunlop type gauge is reversed when used at the rear so will read toe out, 15* works well, 30* is maximum for racing.

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

Is that minutes?

It's defiantly better having had a bit of a drive in the dry.

I don't really have any room to space them out so that's ok keep double checking it's not rubbing.

keep double checking it's not rubbing.

I was looking at Koni's for a nice ride too...? Will look at the ones the ones you mentioned are the protect ones those nice custom jobbies the guy on vzi sells? They look great. From £189 I pair I think....?

I need to see what I have left in travel before the bump stop too. Do they normally need trimming? Feels a bit more bouncy on slow bumpy stuff like speed bumps like its kissing the bump stop or something

I hadn't thought about fitting the tracking gauge on backwards.... I was thinking measuring sticks lol

Thanks for your help!!

It's defiantly better having had a bit of a drive in the dry.

I don't really have any room to space them out so that's ok

I was looking at Koni's for a nice ride too...? Will look at the ones the ones you mentioned are the protect ones those nice custom jobbies the guy on vzi sells? They look great. From £189 I pair I think....?

I need to see what I have left in travel before the bump stop too. Do they normally need trimming? Feels a bit more bouncy on slow bumpy stuff like speed bumps like its kissing the bump stop or something

I hadn't thought about fitting the tracking gauge on backwards.... I was thinking measuring sticks lol

Thanks for your help!!

- Piledriver

- Moderator

- Posts: 22859

- Joined: Sat Feb 16, 2002 12:01 am

Re: Bit odd at speed?

Seconds.

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Bit odd at speed?

60' (minutes) in one degree.

15' = ¼° ....that's ⅛° per side, it'd be pretty hard to get reliable/repeatable measurements much finer than that.

15' = ¼° ....that's ⅛° per side, it'd be pretty hard to get reliable/repeatable measurements much finer than that.

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

So a quarter of a degree toe in? If I'm diying it maybe straight would be easier to shoot for?

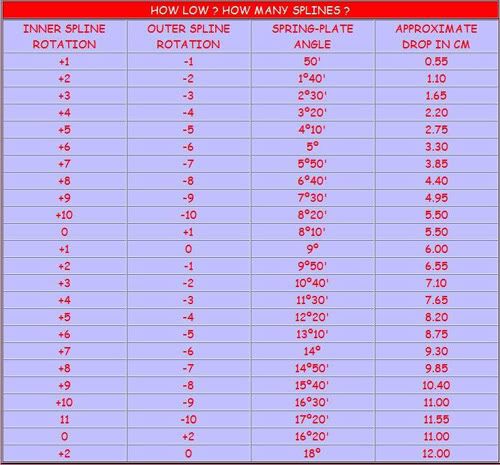

Cheers for the charts. Yh 5.5cm seems about right for what I dropped how do you count inner splines? Use the force ??

how do you count inner splines? Use the force ??

Cheers for the charts. Yh 5.5cm seems about right for what I dropped

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Bit odd at speed?

Where you start is where you start!

If you weren't being silly with me...:

(viewtopic.php?t=110857&postdays=0&postorder=asc&start=0)

Assuming you have already safely removed the spring plate and the torsion bar (and you are still alive or damaged by not having the right tools. There are some other ways of doing this using jacks but I think the post is probably the safer way of doing it especially if you are going to repeat resetting this or another VW some time in the future [know a VW guy that doesn't have more than one now or in the future]) you will have to start the setup all over; if not then, if you have been careful and not lost the original setup, you can start using/working from the chart above.

If not: lightly lube the splines on both ends of the torsion bar then put the torsion bar part way into the splines of the torsion tube and put a spring plate part way on also. The torsion bar will only go into the inner splines of the torsion tube one way as the inner spline count is different for the inside end as compared to the spline count on the outside end of the torsion bar.

The torsion bars are marked L or R on the outside end and each torsion bar must stay installed on the left or right side of the car ... "as marked". This is because they will have taken a "set" to them and are now stronger in the direction they have had to work in. If put in the wrong side they most likely will fail prematurely. If you have abused your IRS half-shafts/axles (as in racing where you do hard launches/starts) then the axles probably have taken a set also and should be used on the same side always.

Also remember that when you use lower your car by a torsion bar preload reset you are also taking some of the preload out of the torsion bar hence making the ride softer. Raising the car by resetting the preload makes the ride stiffer.

I would start by setting a angle finder on the spring plate to set the spring plate at the proper angle setting for your car (check you manual for the proper angle setting for your year and model). If you have already removed the assembly and broken it apart (figuratively not literally), you will do this by clocking the torsion bar and the spring plate back and forth both independently or as a unit. Remember the angle of the spring plate will be closer to level than the original setting if you are lowering the car and hang lower when raising the car. You want to keep the spring plate and torsion bar splines, at this time, not fully assembled/the splines fully in the spring plate and torsion housing while you are trying to get the proper stock angle set.

Carefully pull the torsion bar out of the splines of the torsion tube and as you rotate the torsion bar, while still in contact with the splines, count the splines as you pass them. If you are careful and stay in contact with the splines in the torsion housing you can feel each spline pass. Also:be careful not to "bang/bruise the torsion bar, scratch the protective coating on the torsion bar, or "ding" it as this can lead to reducing the life of the torsion bar.

Once you have achieved the stock spring plate setting on the angle finder then the chart will work for you. If you know the angle you want to be set to the you can make that your original setting then "to heck with the chart" and use the angle gauge.

Don't forget the grommets/donuts before you tighten things up or you will have to start over again. If you use the urethane grommet not only lube the "hole" but the face that the spring plate will ride against. I understand the black urethane grommets/donuts is less prone to "complaining" like the red ones are.

Again, be careful as this is a very dangerous thing to do! Keep your head, hands, arms, tools (they can be sent flying) and anything else you don't want damaged out of the way as the torsion bar/spring plate as the torsion bar can unload so fast you wouldn't be able to start to react before it is finished doing its thing. I had it slip off the suspension stop once and believe me that I had been pre-warned about this myself.

Lee

Re-written to (hopefully) make more sense for someone who has not reset the preload before. It is also a much better thing to do than use some of the gimmicks' to raise or lower you car; e.g., do it right the first time, its cheaper and safer. L

If you weren't being silly with me...:

(viewtopic.php?t=110857&postdays=0&postorder=asc&start=0)

Assuming you have already safely removed the spring plate and the torsion bar (and you are still alive or damaged by not having the right tools. There are some other ways of doing this using jacks but I think the post is probably the safer way of doing it especially if you are going to repeat resetting this or another VW some time in the future [know a VW guy that doesn't have more than one now or in the future]) you will have to start the setup all over; if not then, if you have been careful and not lost the original setup, you can start using/working from the chart above.

If not: lightly lube the splines on both ends of the torsion bar then put the torsion bar part way into the splines of the torsion tube and put a spring plate part way on also. The torsion bar will only go into the inner splines of the torsion tube one way as the inner spline count is different for the inside end as compared to the spline count on the outside end of the torsion bar.

The torsion bars are marked L or R on the outside end and each torsion bar must stay installed on the left or right side of the car ... "as marked". This is because they will have taken a "set" to them and are now stronger in the direction they have had to work in. If put in the wrong side they most likely will fail prematurely. If you have abused your IRS half-shafts/axles (as in racing where you do hard launches/starts) then the axles probably have taken a set also and should be used on the same side always.

Also remember that when you use lower your car by a torsion bar preload reset you are also taking some of the preload out of the torsion bar hence making the ride softer. Raising the car by resetting the preload makes the ride stiffer.

I would start by setting a angle finder on the spring plate to set the spring plate at the proper angle setting for your car (check you manual for the proper angle setting for your year and model). If you have already removed the assembly and broken it apart (figuratively not literally), you will do this by clocking the torsion bar and the spring plate back and forth both independently or as a unit. Remember the angle of the spring plate will be closer to level than the original setting if you are lowering the car and hang lower when raising the car. You want to keep the spring plate and torsion bar splines, at this time, not fully assembled/the splines fully in the spring plate and torsion housing while you are trying to get the proper stock angle set.

Carefully pull the torsion bar out of the splines of the torsion tube and as you rotate the torsion bar, while still in contact with the splines, count the splines as you pass them. If you are careful and stay in contact with the splines in the torsion housing you can feel each spline pass. Also:be careful not to "bang/bruise the torsion bar, scratch the protective coating on the torsion bar, or "ding" it as this can lead to reducing the life of the torsion bar.

Once you have achieved the stock spring plate setting on the angle finder then the chart will work for you. If you know the angle you want to be set to the you can make that your original setting then "to heck with the chart" and use the angle gauge.

Don't forget the grommets/donuts before you tighten things up or you will have to start over again. If you use the urethane grommet not only lube the "hole" but the face that the spring plate will ride against. I understand the black urethane grommets/donuts is less prone to "complaining" like the red ones are.

Again, be careful as this is a very dangerous thing to do! Keep your head, hands, arms, tools (they can be sent flying) and anything else you don't want damaged out of the way as the torsion bar/spring plate as the torsion bar can unload so fast you wouldn't be able to start to react before it is finished doing its thing. I had it slip off the suspension stop once and believe me that I had been pre-warned about this myself.

Lee

Re-written to (hopefully) make more sense for someone who has not reset the preload before. It is also a much better thing to do than use some of the gimmicks' to raise or lower you car; e.g., do it right the first time, its cheaper and safer. L

Last edited by Ol'fogasaurus on Tue Dec 22, 2015 2:58 am, edited 2 times in total.

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Bit odd at speed?

Toe angle specs are considered "toe-in" when the value is positive, "toe-out" when it's negative; i.e. -5' toe indicates slightly toed out.

Factory spec for the total toe on swingaxle is -5', ±10' ...in other words, from 15' toed out to 5' toed in - but there's an additional requirement that both sides match within 10'.

If one side was at -10' and the other at +5', the total toe would be right on at -5' but the 10' "matching" rule would be broken (potentially causing noticeable "dog-walking")...nudge them both to -5' where they match, and the result will be a total toe-out of 10' (still within spec).

In practice there's sufficient deflection in the tires & torsion bar bushings to affect the readings, so it's a good idea to roll the car back at least a few feet, then forward again each time you take a reading.

http://oacdp.org/wog72/036_v.png

Factory spec for the total toe on swingaxle is -5', ±10' ...in other words, from 15' toed out to 5' toed in - but there's an additional requirement that both sides match within 10'.

If one side was at -10' and the other at +5', the total toe would be right on at -5' but the 10' "matching" rule would be broken (potentially causing noticeable "dog-walking")...nudge them both to -5' where they match, and the result will be a total toe-out of 10' (still within spec).

In practice there's sufficient deflection in the tires & torsion bar bushings to affect the readings, so it's a good idea to roll the car back at least a few feet, then forward again each time you take a reading.

http://oacdp.org/wog72/036_v.png

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

Thanks for taking the time to write that Lee, it's very helpful!Ol'fogasaurus wrote:Where you start is where you start!

If you weren't being silly with me...:

(viewtopic.php?t=110857&postdays=0&postorder=asc&start=0)

Assuming you have already safely removed the spring plate and the torsion bar (and you are still alive or damaged by not having the right tools. There are some other ways of doing this using jacks but I think the post is probably the safer way of doing it especially if you are going to repeat resetting this or another VW some time in the future [know a VW guy that doesn't have more than one now or in the future]) you will have to start the setup all over; if not then, if you have been careful and not lost the original setup, you can start using/working from the chart above.

If not: lightly lube the splines on both ends of the torsion bar then put the torsion bar part way into the splines of the torsion tube and put a spring plate part way on also. The torsion bar will only go into the inner splines of the torsion tube one way as the inner spline count is different for the inside end as compared to the spline count on the outside end of the torsion bar.

The torsion bars are marked L or R on the outside end and each torsion bar must stay installed on the left or right side of the car ... "as marked". This is because they will have taken a "set" to them and are now stronger in the direction they have had to work in. If put in the wrong side they most likely will fail prematurely. If you have abused your IRS half-shafts/axles (as in racing where you do hard launches/starts) then the axles probably have taken a set also and should be used on the same side always.

Also remember that when you use lower your car by a torsion bar preload reset you are also taking some of the preload out of the torsion bar hence making the ride softer. Raising the car by resetting the preload makes the ride stiffer.

I would start by setting a angle finder on the spring plate to set the spring plate at the proper angle setting for your car (check you manual for the proper angle setting for your year and model). If you have already removed the assembly and broken it apart (figuratively not literally), you will do this by clocking the torsion bar and the spring plate back and forth both independently or as a unit. Remember the angle of the spring plate will be closer to level than the original setting if you are lowering the car and hang lower when raising the car. You want to keep the spring plate and torsion bar splines, at this time, not fully assembled/the splines fully in the spring plate and torsion housing while you are trying to get the proper stock angle set.

Carefully pull the torsion bar out of the splines of the torsion tube and as you rotate the torsion bar, while still in contact with the splines, count the splines as you pass them. If you are careful and stay in contact with the splines in the torsion housing you can feel each spline pass. Also:be careful not to "bang/bruise the torsion bar, scratch the protective coating on the torsion bar, or "ding" it as this can lead to reducing the life of the torsion bar.

Once you have achieved the stock spring plate setting on the angle finder then the chart will work for you. If you know the angle you want to be set to the you can make that your original setting then "to heck with the chart" and use the angle gauge.

Don't forget the grommets/donuts before you tighten things up or you will have to start over again. If you use the urethane grommet not only lube the "hole" but the face that the spring plate will ride against. I understand the black urethane grommets/donuts is less prone to "complaining" like the red ones are.

Again, be careful as this is a very dangerous thing to do! Keep your head, hands, arms, tools (they can be sent flying) and anything else you don't want damaged out of the way as the torsion bar/spring plate as the torsion bar can unload so fast you wouldn't be able to start to react before it is finished doing its thing. I had it slip off the suspension stop once and believe me that I had been pre-warned about this myself.

Lee

Re-written to (hopefully) make more sense for someone who has not reset the preload before. It is also a much better thing to do than use some of the gimmicks' to raise or lower you car; e.g., do it right the first time, its cheaper and safer. L

When I did it, I used a high quality heavy weight trolley jack on the spring plate and the car was on a 4 post ramp. Even still I managed to let it "fling" an inch or so and it made my check my fingers! I thought it was rested but it was resting on the stub axle and as I moved it pinged a little. Even that small 1 inch drop in angle had enough power in it to make me think!

When I did it (first time I'd done this) I was fitting new bushes but was very careful not to disturb the inner splines, just levered the assembly out a bit and tapped in the torsions bar and kept doing this till it came free, having made about 5 or 6 datum marks on the spring plate and bar to locate it one spline lower accurately.

I found I had to remove the wings to get a good line of sight and also a good swing with the hammer as a couple inch swing wasn't cutting the mustard!

Next on the list is a slimmer sump lol

Also wondering if I should lower the front or not, I'm converting to discs on the new year hopefuly, but want to keep nice section of good rubber up front, not some 145 section rubber band... Tempted to go dropped spindles and adjusters and let the spindles do the 2.5in drop and then use the adjusters to raise it for clearance..... As most struggle with that with dropped spindles. But that'll be after my wallet recovers from xmas!

Marc,

Cheers for clearing that up, I think I was uneven before as it felt different on left and right turns which makes sense.

So as BBB states and VW say, I want to be a smudge toe in really. Guessing that's more stable? BBB hinted that more was for racing, does that imply more will induce oversteer?

Cheers

Andy

- Marc

- Moderator

- Posts: 23741

- Joined: Thu May 23, 2002 12:01 am

Re: Bit odd at speed?

The factory specs assume stock ride height and may not be ideal if that's been altered, but for swingaxle they call for slight toe-out in the rear.andy198712 wrote:...So as BBB states and VW say, I want to be a smudge toe in really. Guessing that's more stable? BBB hinted that more was for racing, does that imply more will induce oversteer?...

For IRS (double-joint) the rear toe spec was originally +10' ±10' - between straight-up and toed in, but was changed to 0 ±15'.

Tractive effort causes the rear wheels to pull forward and thus toe in when under power; conversely there's a tendency towards toe-out on deceleration - and yes, rear toe-out does encourage throttle-off oversteer so too much is generally undesirable.

-

buildabiggerboxer

- Posts: 621

- Joined: Wed Mar 25, 2009 12:50 pm

Re: Bit odd at speed?

Andy, More rear toe in makes them under steer big time, going over 30' is wasting power efficiency, such an extreme setting was often used with huge 30mm rear torsion bars, don't go there for street use, one thing I find with urethane bushes is they often come up so tight the 'stiction' can affect setting rear toe, possibly one reason why the bigger 10/15' settings found favour, it was just plain Easier to read the scale reliably, the same problem may drive me over to a uniball rear pivot, it's so difficult to corner weight IRS cars for the same reason, I've had up to 50lb nonsense readings just on one side, check again after adjusting, time consuming, and you have another nonsense reading, so the whole car is off possibly 100 lb across the rear axle and now the front is nonscence also, all down to the rear bushes having a ton of friction sticksion. All I can do in such cases is balance the front axle so I can brake the damn thing properly, welcome in coil overs and uniball, provided they fit the RR's.andy198712 wrote:

So as BBB states and VW say, I want to be a smudge toe in really. Guessing that's more stable? BBB hinted that more was for racing, does that imply more will induce oversteer?

Cheers

Andy

Why not Try the front with just the drop spindles alone ?, time and time again folk build in a ton of weight and crap that's never used except in the pub and on forum chit chat, chances are you wont play with the ride height after a 2 1/2" drop anyway, same ish deal on the front toe in, 20' works well, but worn front bearings make that a nonsense also, and please stay away from all that parallel front toe chat.

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Bit odd at speed?

Andy, when I use a floor jack to do this I also put a chain around to floor jacks front axle something in the car above (I think the URL shows the chain; I didn't go back to the URL to check but I think I did show it in a picture) the jack to keep the floor jack and the car working together. Even with the floor jack tied to the car via the chain the front end of the floor jack will lift up.

Like I said, this is something you want to think and stay a head of. It is fairly easy to do and also fairly dangerous if you aren't prepared for something bad to happen. Like you said: having the car on jack stands is a very good idea also.

As far as the front end goes, I also think it is best to start with dropped spindles then do the hard stuff after. You also might want to replace anything with some time on them so you don't have to do an alignment twice ($$$).

Also remember that if you have too much rake (nose lower than the rear of the car, which I don't think you are planning on but a reminder just-in-case) you might have to use the longer bolts and shim the lower tube to get the proper caster adjustment.

Lee

Like I said, this is something you want to think and stay a head of. It is fairly easy to do and also fairly dangerous if you aren't prepared for something bad to happen. Like you said: having the car on jack stands is a very good idea also.

As far as the front end goes, I also think it is best to start with dropped spindles then do the hard stuff after. You also might want to replace anything with some time on them so you don't have to do an alignment twice ($$$).

Also remember that if you have too much rake (nose lower than the rear of the car, which I don't think you are planning on but a reminder just-in-case) you might have to use the longer bolts and shim the lower tube to get the proper caster adjustment.

Lee

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

Marc wrote:The factory specs assume stock ride height and may not be ideal if that's been altered, but for swingaxle they call for slight toe-out in the rear.andy198712 wrote:...So as BBB states and VW say, I want to be a smudge toe in really. Guessing that's more stable? BBB hinted that more was for racing, does that imply more will induce oversteer?...

For IRS (double-joint) the rear toe spec was originally +10' ±10' - between straight-up and toed in, but was changed to 0 ±15'.

Tractive effort causes the rear wheels to pull forward and thus toe in when under power; conversely there's a tendency towards toe-out on deceleration - and yes, rear toe-out does encourage throttle-off oversteer so too much is generally undesirable.

Thats good point on the settings are designed for stock height... cheers buddy

-

andy198712

- Posts: 2433

- Joined: Wed Apr 13, 2011 1:01 pm

Re: Bit odd at speed?

buildabiggerboxer wrote:Andy, More rear toe in makes them under steer big time, going over 30' is wasting power efficiency, such an extreme setting was often used with huge 30mm rear torsion bars, don't go there for street use, one thing I find with urethane bushes is they often come up so tight the 'stiction' can affect setting rear toe, possibly one reason why the bigger 10/15' settings found favour, it was just plain Easier to read the scale reliably, the same problem may drive me over to a uniball rear pivot, it's so difficult to corner weight IRS cars for the same reason, I've had up to 50lb nonsense readings just on one side, check again after adjusting, time consuming, and you have another nonsense reading, so the whole car is off possibly 100 lb across the rear axle and now the front is nonscence also, all down to the rear bushes having a ton of friction sticksion. All I can do in such cases is balance the front axle so I can brake the damn thing properly, welcome in coil overs and uniball, provided they fit the RR's.andy198712 wrote:

So as BBB states and VW say, I want to be a smudge toe in really. Guessing that's more stable? BBB hinted that more was for racing, does that imply more will induce oversteer?

Cheers

Andy

Why not Try the front with just the drop spindles alone ?, time and time again folk build in a ton of weight and crap that's never used except in the pub and on forum chit chat, chances are you wont play with the ride height after a 2 1/2" drop anyway, same ish deal on the front toe in, 20' works well, but worn front bearings make that a nonsense also, and please stay away from all that parallel front toe chat.

Luckily (in some ways) i put in stock black rubber bushes of decent quality (seemingly)

Yeah could give them a go, need to buy them first though, but got some stock disk spindles i could sell too, might be a month or two but gives me to time to rebuild the callipers i got.

mechanicals on the front end and rear now bushes and bearings wise are under a year and under 4000 miles old or less. and get regular checks to make sure nothing has split or got play ect so can go ahead and try out the alignment tool at the car club and see if i can make heads or tails of it