I know it would seem that way, but both will get the same amount of pressure.The Wild Kids wrote:WIth the dual carb set up, do you have to equalize how much is going to each carb and how do you do it? Seems like one would get more flow than the other unless they were of equal size.

The wild kids

So...you wanna go turbo?

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

I know all of that sounds correct...and in some very insignificant way...it is correct. I had typed out a bunch of equations dealing with the physics of pressure....but then decided to explain it in very simple terms.ntsqd wrote:Whether or not they get the same air volume depends on the plumbing geometry. If they have roughly the same amount of bends in each runner and they are roughly the same length they should be pretty close. This is a topic that you can make as complicated as you want, or just use some simple RoT's & get it done.

I am wondering why one would use that E2000 pump in a carb'd system. Would result in a lot of wasted energy pumping fuel, only to return it to the tank.

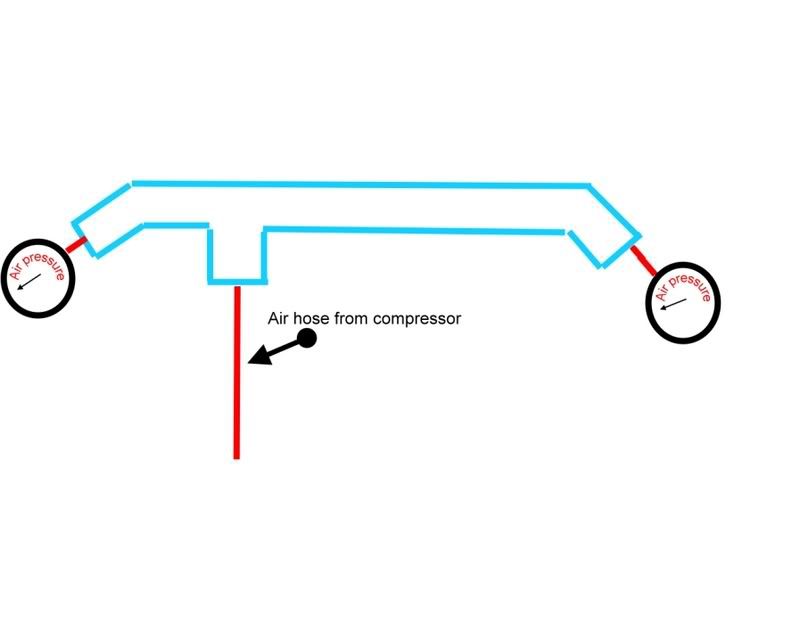

Sorry about the cruddy picture, but it will serve it's purpose....

Lets forget about the turbo charger and the carbs for a minute. Lets just say that you have some ducting that looks like the one in the picture. Now lets say that you have capped off and welded shut all three openings so it is air tight. Now we drill and tap a hole in each end cap. On the caps at either end, we install air pressure gauges, like the ones found on your air compressor, and in the end cap that is clearly off-center...we screw in an air hose that is hooked to your air compressor. As I mentioned...the inlet tube of where the compressor is hooked to is purposely off center of the tubing. Now....turn on your air compressor and see the results. Do you think that the pressure gauge on the short side will have more pressure than the one on the long side? Of course not. Just like on your air compressor tank, is there more air pressure at the bottom of the tank than the top? No...of course not. So that is cut and dried about the pressure. For one side to have more pressure than the other...in a pressurized chamber...well...it's back to physics...it's just not going to happen.

But what about "volume" of air you say. Won't the one on the short side receive more volume? Well...yes it will...for a period of about 0.5 milliseconds. Lets continue to test using this same pipe. But this time we are going to take the pressure gauges out of the ends of the tube. And lets say that your air compressor puts out a VERY large CFM...(lots of volume). Now go over and crack the air valve open really fast letting that air into the tube. The short side will start blowing the greater air volume first. But what happens when that tube reaches a unified pressure in a blink of an eye? Yep, you guess it, the same amount of air will be blowing out of both ends. The pressure will be the same right where the air came in and it will be the same at the far end. As I said...there will be that blink of an eye when pressure equalizes, but I can tell you this...is not enough for a race car to be concerned with. Now...if you are talking about twin turbos...parallel (one on each side)...A couple companies make a big deal about both pressure ducts being equal length. Normally the ones that put the turbos all they way at the rear of the car. I suppose that this could be considered to have some validity to it...An extreme example you be if you had one turbo right up against the intake and the other at the back of the car. One both pressure ducts had ten pounds of pressure in them, it would not matter...but the short tube had less area to build to ten pounds, so it's short tube will get pressure faster and then the pressure might go hunting down the other turbo pipe in the correct circumstances....But really...if you stop and take that into consideration...The end result would still have the same outcome. I mean...when pressure met pressure...it would just look for another way to escape and that would be through the engine. So...no...you won't feel any difference through your dual carbs and different pressures. WHEW!

Okay...now the pump. The E2000 is cheap, it's dependable, it has barbed fitting on it so it can be just hose clamped on and the 95 psi is certainly not needed....the pump is for fuel injection...But an electric pump for a boosted engine...one that is even running ten pounds of boost will need at the very minimum of a pump that puts out 14 pounds of pressure. And for guys like me that run more boost (20psi), I need a pump that puts out a minimum of 25 pounds. So...find me an electric pump in a recking yard that has all the characteristics of the E2000, for a price of around 15 bucks...that only runs 25 or 30 pounds...and maybe I will buy that one instead of the E2000.

- runslikeapenguin

- Posts: 719

- Joined: Tue Nov 07, 2006 7:42 pm

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

No, The pressure is the same on both ends. If 1 side has 1 pound then so does the other. The volume of air might be different for a split second due to having to travel a little further...but I can't even convey to you what a non issue and insignificant topic this is.

Listen...the light from the television WILL take longer to get to you if you sat 1 foot back...Did it screw up the show you were watching? It is that insignificant.

Like I said...I don't want to go into a huge amount of figures here...but here is just a short one. Figure out the volume of that 2 inch pipe from the turbo inlet to it's end. I doubt it would hold half a gallon...but lets just say that is does. So here is just some quick numbers for you to fiddle with. 1 cubic foot = 7.48 gallons. Now lets say you have a turbo that spits out 300 CFM (cubic feet per minute) So divided 0.5 and 7.48. So you need to fill 0.06 of space with something that pushes in roughly 5000 times it's volume.

Ah...forget it...Lets just say that it means nothing and move on to things that will matter.

Listen...the light from the television WILL take longer to get to you if you sat 1 foot back...Did it screw up the show you were watching? It is that insignificant.

Like I said...I don't want to go into a huge amount of figures here...but here is just a short one. Figure out the volume of that 2 inch pipe from the turbo inlet to it's end. I doubt it would hold half a gallon...but lets just say that is does. So here is just some quick numbers for you to fiddle with. 1 cubic foot = 7.48 gallons. Now lets say you have a turbo that spits out 300 CFM (cubic feet per minute) So divided 0.5 and 7.48. So you need to fill 0.06 of space with something that pushes in roughly 5000 times it's volume.

Ah...forget it...Lets just say that it means nothing and move on to things that will matter.

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

- sinistervw

- Posts: 699

- Joined: Fri Jan 25, 2002 12:01 am

- runslikeapenguin

- Posts: 719

- Joined: Tue Nov 07, 2006 7:42 pm

- tuff_puff

- Posts: 1055

- Joined: Sun Jul 02, 2006 1:30 pm

no i think its from the time you press on the gas pedal. the butterflys open, and air rushes through the carberator('s) "dropping" pressure on one side. the thing is the turbo is pushing the air so fast that before the pressure has a chance to really drop at all. it is haveing the turbo push more air then what was even in the tube in the first place (thats called boost the whole reason we want turbos for) so therefor the "pressure drop" is so amazeingly insignifigant

that there is only ONE person in the WHOLE WORLD who is worried about it.

that there is only ONE person in the WHOLE WORLD who is worried about it.

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

Yeah...Tuff..take that (fruity).

Also....there have been some new developments in turbo design...what you said still kinda of stand true with that fact that they pull good boost when under load. But there are drag racers these days that are pulling nearly 30 psi of boost when getting ready to launch.

Also....there have been some new developments in turbo design...what you said still kinda of stand true with that fact that they pull good boost when under load. But there are drag racers these days that are pulling nearly 30 psi of boost when getting ready to launch.

- david58

- Moderator

- Posts: 14100

- Joined: Sun Oct 23, 2005 6:14 pm

So Scott. What is the next step in a turbo set up that is important past the connection between the turbo and the carb? Do you have a diagram you could post showing a turbo set up with one carb with all the important pieces in the order they go in making it work properly? I think it would make it easier to discuss the system for anyone that doesn't know jack about a turbo like me. A hand drawn diagram will work.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- scott the viking

- Posts: 3864

- Joined: Fri Apr 23, 2004 8:35 am

You know...that's not a bad idea. I don't have anything handy...but I sure can put something together...might even have a picture or two I could dig up.David58bug wrote:So Scott. What is the next step in a turbo set up that is important past the connection between the turbo and the carb? Do you have a diagram you could post showing a turbo set up with one carb with all the important pieces in the order they go in making it work properly? I think it would make it easier to discuss the system for anyone that doesn't know jack about a turbo like me. A hand drawn diagram will work.

- david58

- Moderator

- Posts: 14100

- Joined: Sun Oct 23, 2005 6:14 pm

Well like I said I don't know jack about a turbo I want to build one after reading your post. Hopefully Chance will be buying one from you he don't like getting his hands dirty. I always thought a turbo was the wrong way to go. I see now after reading your thread it is far from being the wrong way it is the easy way.scott the viking wrote:You know...that's not a bad idea. I don't have anything handy...but I sure can put something together...might even have a picture or two I could dig up.David58bug wrote:So Scott. What is the next step in a turbo set up that is important past the connection between the turbo and the carb? Do you have a diagram you could post showing a turbo set up with one carb with all the important pieces in the order they go in making it work properly? I think it would make it easier to discuss the system for anyone that doesn't know jack about a turbo like me. A hand drawn diagram will work.

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- runslikeapenguin

- Posts: 719

- Joined: Tue Nov 07, 2006 7:42 pm

- tuff_puff

- Posts: 1055

- Joined: Sun Jul 02, 2006 1:30 pm

ntsqd wrote:

Tuff Puff, I feel that you've been baiting me for some time and I'm bloody tired of it. Either back off or come clean with what ever your problem with me is.

I would not say baiting is the right term for it. its just that this is a GREAT thread. probably the best we have had in a while. and it bums me out too see someone murk it all up with completely useless banter. for instance JB weld your reg/carb COME ON. i know i have been guilty of the, duct tape fix here and there. but when it comes to putting ghetto weld in my carb?