Page 6 of 8

Re: Budget 100x71 Build

Posted: Mon Jan 18, 2021 4:54 am

by Eddie010

cal 67 wrote: ↑Mon Jan 18, 2021 4:09 am

Eddie010 wrote: ↑Sun Jan 17, 2021 10:39 pm

Hope you know, but you switched nr 1 and 2. Rod nr 2 is cilinder nr 1

Lol! They're just laid out that way to show the stamps on the rods! Still though, all the stamps should face the pulley side.

Ok no problem.

I find the forces drawing and the way to place the tangs interesting.

In one of the books I found that the tangs should face up.. but in other books they say it does not matter...

Re: Budget 100x71 Build

Posted: Tue Jan 19, 2021 4:59 pm

by cal 67

Eddie010 wrote: ↑Sun Jan 17, 2021 10:39 pm

Hope you know, but you switched nr 1 and 2. Rod nr 2 is cilinder nr 1

I just noticed what you meant. Those number markings were from the guy that sold me them secondhand. It doesn't matter, as I don't even think he balanced them. I have a balancing jig for various rod styles on the way. A guy made it for me - T1, T2 2.0L, Honda, and Chevy big end attachments, and 22 and 24 small ends.

Re: Budget 100x71 Build

Posted: Wed Jan 20, 2021 9:48 pm

by cal 67

Think my #1 bearing's thrust interference is too tight, messing with the radial clearance. I need to investigate. It's not spinning as smoothly as I'd like. The bearing measured fine in the saddle.

Think I put this gear backwards

. Thought that raised area was a built-in racer spacer....nope.

Re: Budget 100x71 Build

Posted: Wed Jan 20, 2021 9:49 pm

by cal 67

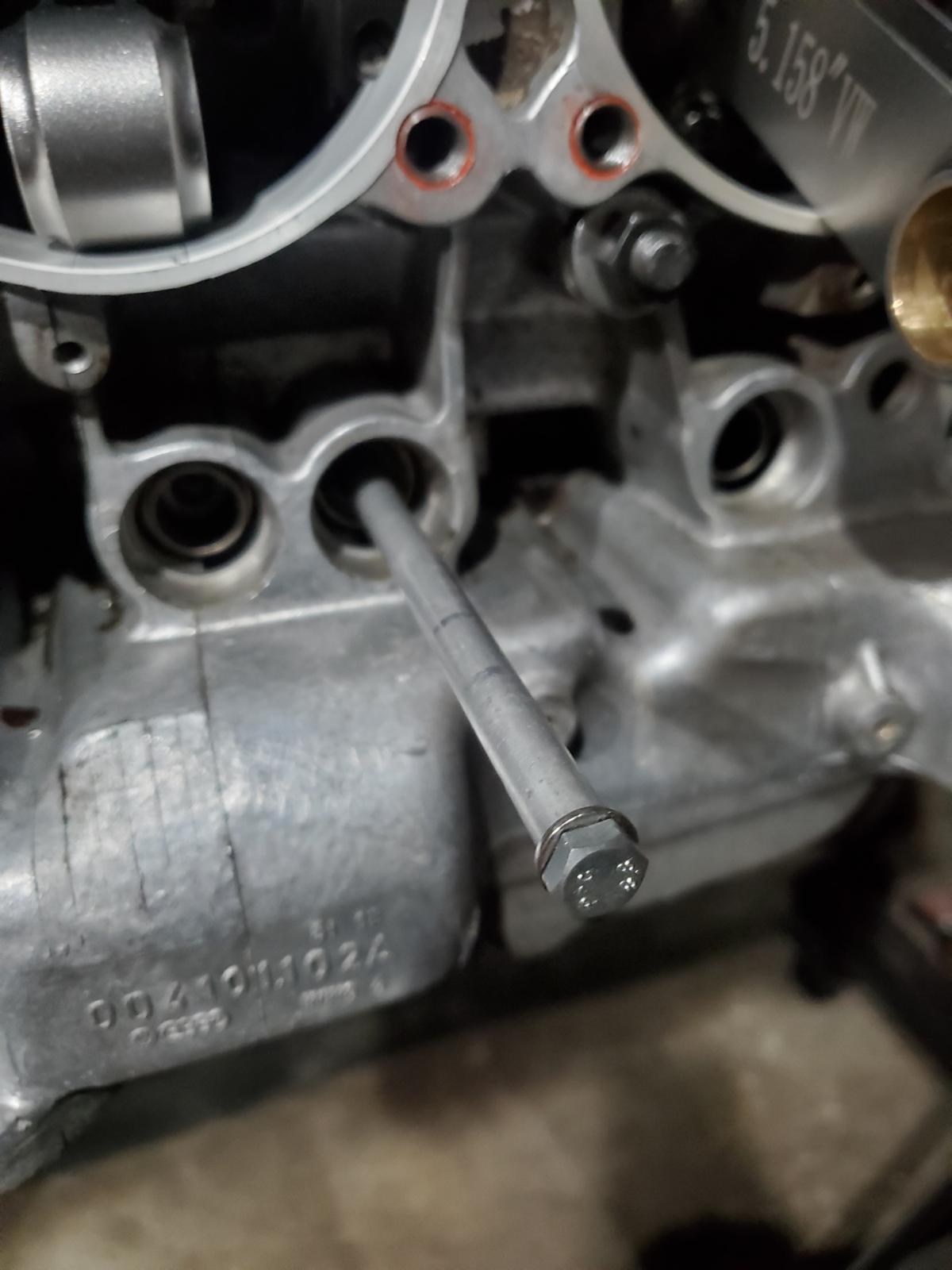

Check Everything! The #4 exhaust lifter hanging up on a casting bump after the thrust bearing:

Did some quick filing, and got some needed clearance. I'll do more later. Just need to do cam timing and see where my decks are.

Re: Budget 100x71 Build

Posted: Wed Jan 20, 2021 9:51 pm

by cal 67

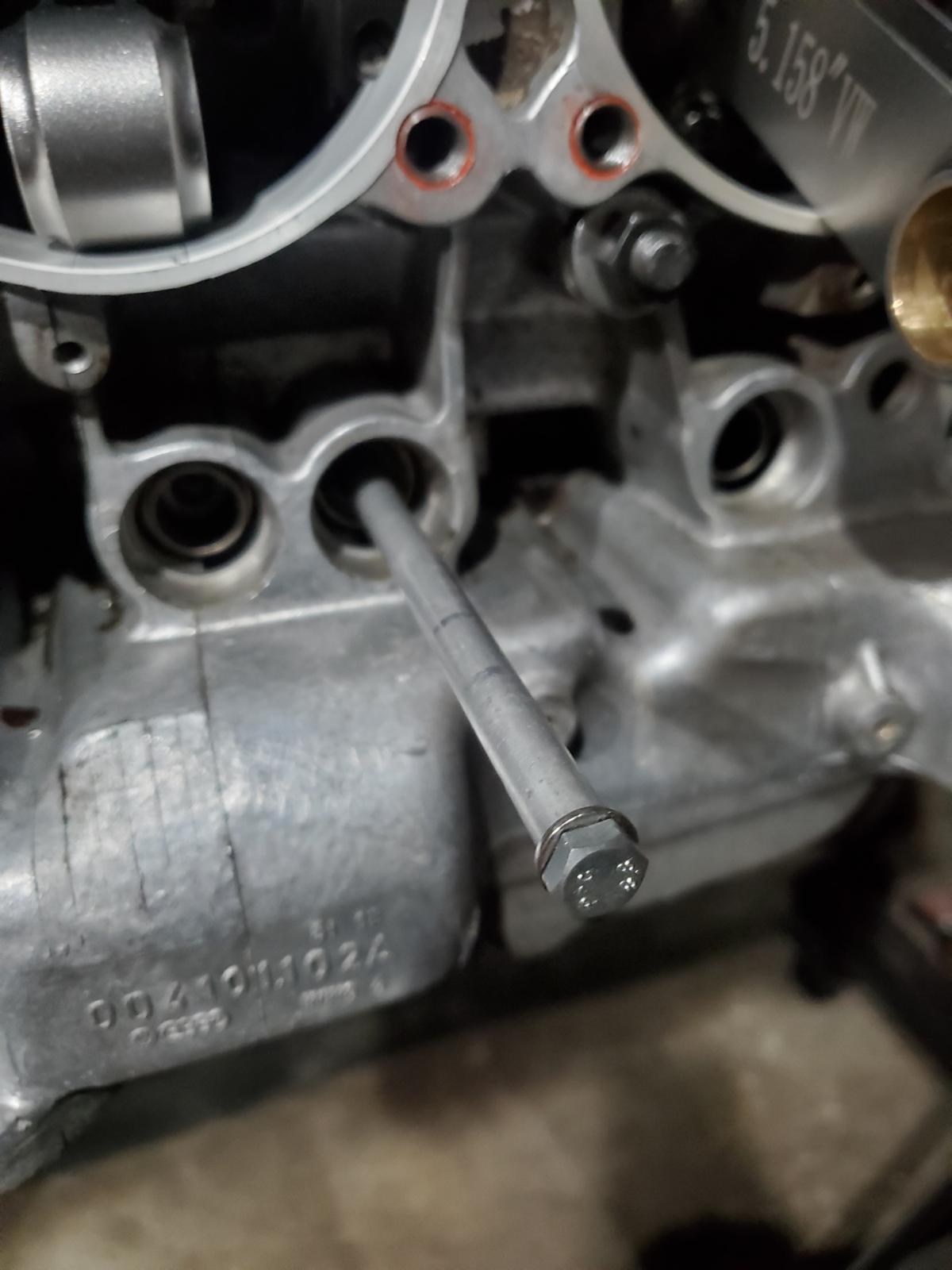

JFats808 from thesamba gave me this tool years ago: it's one of the best tools I have - just a stock lifter with a half pushrod epoxied in.

Case is closed up now.

Re: Budget 100x71 Build

Posted: Thu Jan 21, 2021 5:52 am

by twodollardoug

What did you use to seal the case halves?

Re: Budget 100x71 Build

Posted: Thu Jan 21, 2021 7:37 am

by cal 67

twodollardoug wrote: ↑Thu Jan 21, 2021 5:52 am

What did you use to seal the case halves?

Nothing. I'm only mocking it. An engine should come apart and go together at least three times before it's complete.

Re: Budget 100x71 Build

Posted: Thu Jan 21, 2021 7:47 am

by twodollardoug

Ya, I thought you were done and closed it up.

Re: Budget 100x71 Build

Posted: Fri Jan 22, 2021 10:09 am

by cal 67

If you're going to use these pistons, make sure you point the scribed-in arrows toward the pulley. The short side points up on 1 and 2, and down on 3 and 4.

I'm going to figure deck and trim these guys. Looks around 5mm.

Re: Budget 100x71 Build

Posted: Sat Jan 23, 2021 8:47 pm

by cal 67

Re: Budget 100x71 Build

Posted: Mon Jan 25, 2021 2:17 pm

by cal 67

Pretty sure my LSA is 112°

. It's advertised as a 106°. May not be a bad thing though. I'ma do more investigating later. I want the majority of my power to be from about 4K-7.5K. You think 112 is fine?

Oh, I was mistaken about the loss of lift. My cam is lifting .429" at the lobe, so it's accurate in that aspect.

Re: Budget 100x71 Build

Posted: Tue Jan 26, 2021 11:03 pm

by Clatter

Love the details.. Thanks for sharing.

Those rods have an offset?

Now that you have some extra room to the lifter heads, you could pick a bigger cam.

Looking forward to seeing lifts with the Pauter rockers.

Seeing as how the factory rockers lift so much less on the exhaust side..

Can't wait to see the heads.

Re: Budget 100x71 Build

Posted: Wed Jan 27, 2021 10:20 am

by cal 67

Clatter wrote: ↑Tue Jan 26, 2021 11:03 pm

Love the details.. Thanks for sharing.

Those rods have an offset?

Now that you have some extra room to the lifter heads, you could pick a bigger cam.

Looking forward to seeing lifts with the Pauter rockers.

Seeing as how the factory rockers lift so much less on the exhaust side..

Can't wait to see the heads.

I actually will be using a physically bigger cam because the lower lift will allow a larger base circle to fit on the blank. This Q is too much. 290° @ .050" is at least good for 9,000 rpm. Also, I'd need to set compression past 13:1 to get a decent psi. I expected it to fall short. Looking at the "N" cam now. I can set it to about 12.2:1 cr on pump fuel and it'll be happy.

Re: Budget 100x71 Build

Posted: Mon Feb 01, 2021 9:57 pm

by cal 67

Anybody know how to pop this sensor out without damaging it? Thinking the only way is to grind it and punch it out.

ARP flywheel bolts arrived

Measured dome volume. 100mm piston, .106" dome height, the flat portion was .250" down the hole - 44cc. If I'm not mistaken, that's a 5.91cc dome.

Re: Budget 100x71 Build

Posted: Thu Feb 04, 2021 12:18 pm

by cal 67

Spent a few hours today checking decks with all my pistons and cylinders. One of my case decks looks to be .0015" higher than the rest. Compression heights vary by .002"., and cylinders by .002". I guess some juggling is in-order after I cut down the barrels. When measuring each of the barrels on the table with a caliper (I'm pretty good at it), I get much different numbers than when bolted into the engine. I can't imagine why. No burrs, hang-ups, etc. I think the barrels' bores are not perfectly parallel to the exterior cuts.

Decided to go back to the P cam. I'll get a slightly larger base circle diameter this way, and have less .050" duration. Ideally, I'd like about 275°, but I'll settle for 280. A lot of Nords are finding success with this cam.

Waiting to weld my heads. Maybe this weekend...