D-Jet 'progression problems'

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

D-Jet 'progression problems'

Hello,

I'm currently having a few issues with my 1973 412LE variant running stock D-Jet injection. It seems to have all the symptoms of a misfire whilst running under load at about 2000 rpm or so.

So far, I have:

Changed the ignition leads

Changed the points, condensor and distributor cap, and timed to spec with a timing light (have also set the dwell and idle speed)

Set the valve clearances

Cleaned the FI trigger points in the distributor, and checked the metal braid that attaches to the points plate.

Cleaned and checked the throttle position sensor

Cleaned all the earths I can find (especially the ones that bolt to the top of the engine case)

Checked and set the fuel pressure to 28psi using a fuel pressure gauge (though not under load, as I guess that means having someone sitting in the back looking at the guage while I'm driving?)

None of this has solved the problem.

I would like to change all the rubber hoses in the engine bay to eliminate any potential air leaks - could someone tell me what sizes and lengths I need? I guess I'll need to change the inlet manifold gaskets as well.

I've not changed the spark plugs yet, but I suppose those will be an easy thing thing to swap out.

Can anyone think of anything else obvious that I need to check? I've not changed the fuel filter - could it be that? Is there a modern equivalent filter I can use to replace the square one?

The car starts and idles perfectly. (I had a few problems with the FI wiring harness being too close to no 3 ignition lead, but that's solved now).

Many thanks.

I'm currently having a few issues with my 1973 412LE variant running stock D-Jet injection. It seems to have all the symptoms of a misfire whilst running under load at about 2000 rpm or so.

So far, I have:

Changed the ignition leads

Changed the points, condensor and distributor cap, and timed to spec with a timing light (have also set the dwell and idle speed)

Set the valve clearances

Cleaned the FI trigger points in the distributor, and checked the metal braid that attaches to the points plate.

Cleaned and checked the throttle position sensor

Cleaned all the earths I can find (especially the ones that bolt to the top of the engine case)

Checked and set the fuel pressure to 28psi using a fuel pressure gauge (though not under load, as I guess that means having someone sitting in the back looking at the guage while I'm driving?)

None of this has solved the problem.

I would like to change all the rubber hoses in the engine bay to eliminate any potential air leaks - could someone tell me what sizes and lengths I need? I guess I'll need to change the inlet manifold gaskets as well.

I've not changed the spark plugs yet, but I suppose those will be an easy thing thing to swap out.

Can anyone think of anything else obvious that I need to check? I've not changed the fuel filter - could it be that? Is there a modern equivalent filter I can use to replace the square one?

The car starts and idles perfectly. (I had a few problems with the FI wiring harness being too close to no 3 ignition lead, but that's solved now).

Many thanks.

- raygreenwood

- Posts: 11910

- Joined: Wed Jan 22, 2003 12:01 am

If all else is well....this is usually attributed to an advance unit issue or a slop issue in the throttle valve switch...and is also very common with a EFI wiring harness issue.

Is this mis fire under load or when crusing?

On flat open highways or roads, while crusing....you would tend to be at the same approximate throttle setting many times. If the throttle valve switch has slop in it (common)...it can have and on-off oscillation. This is actually what is known as the "bucking" syndrome. It is cused by one of three things in the throttle valve switch and sometimes combinations of the three.

(1) excessive wear or slack at the D-shaped bushing in the center of the throttle valve switch...causing excessive float which causes one or both of the next two problems.

(2) Improper initial adjustment of the TVS causing the contact to be between enrichment pads on the circuit board at the wrong time

(3) excessive slack between the front and rear pins for the floating contacts in the TVS. This causes the forked contacts to float between the two pins (the rearward one is fuel shut-off and the forward one is enrichment). If during cruise it contacts the rearward pin due to either slop in pin spacing or slop in the "D" bushing on the TB shaft....it abruptly shuts off fuel causing a lurch. Likewise if it contacts neither pin...you do not get either shut off or enrichment that a very minute throttle movement may require. Or....if it contacts thr forward enrichment pin but cannot stay engaged to it....lurching.

Also...advance unit wise....a leak in the vacuum chamber can cause this...or if the hole in the arm on the breaker plate pin is worn oval then it may slip up and down causing odd movements. Ray

Is this mis fire under load or when crusing?

On flat open highways or roads, while crusing....you would tend to be at the same approximate throttle setting many times. If the throttle valve switch has slop in it (common)...it can have and on-off oscillation. This is actually what is known as the "bucking" syndrome. It is cused by one of three things in the throttle valve switch and sometimes combinations of the three.

(1) excessive wear or slack at the D-shaped bushing in the center of the throttle valve switch...causing excessive float which causes one or both of the next two problems.

(2) Improper initial adjustment of the TVS causing the contact to be between enrichment pads on the circuit board at the wrong time

(3) excessive slack between the front and rear pins for the floating contacts in the TVS. This causes the forked contacts to float between the two pins (the rearward one is fuel shut-off and the forward one is enrichment). If during cruise it contacts the rearward pin due to either slop in pin spacing or slop in the "D" bushing on the TB shaft....it abruptly shuts off fuel causing a lurch. Likewise if it contacts neither pin...you do not get either shut off or enrichment that a very minute throttle movement may require. Or....if it contacts thr forward enrichment pin but cannot stay engaged to it....lurching.

Also...advance unit wise....a leak in the vacuum chamber can cause this...or if the hole in the arm on the breaker plate pin is worn oval then it may slip up and down causing odd movements. Ray

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Thanks Ray - that's given me a few more pointers to look at before I pull out my last remaining hairs!

When I checked my TVS, I pulled off the cover, and cleaned the tracks with contact cleaner. The contacts didn't seem too worn though. I believe that it is set up correctly, as the idle circuit is definitely switched on when the throttle is closed (the idle mixture switch on top of the ECU works). That said, I've not yet followed the full adjustment instructions here http://www.pelicanparts.com/techarticle ... _17-18.jpg

I may have a spare one in my box of D-jet parts at home that I can swap in - I'll look tonight. If not, I'll pull it again, adjust it as above and have a look at the bushing. Where I'd find another one though, I just don't know!

The misfiring is generally when accelerating. If I accelerate very slowly, then it's often OK. If I'm more enthusiastic with the accelerator, then it's more likely to have a problem. That said, I do occasionally get occasional 'blips' whilst at cruising speed as well.

I do have a spare distributor, but the vacuum unit is an advance/retard unit (2 vacuum pipes to the vacuum can), whereas mine only has the advance feature (1 vacuum pipe to the vacuum can). I guess I won't be able to use that one.

When I checked my TVS, I pulled off the cover, and cleaned the tracks with contact cleaner. The contacts didn't seem too worn though. I believe that it is set up correctly, as the idle circuit is definitely switched on when the throttle is closed (the idle mixture switch on top of the ECU works). That said, I've not yet followed the full adjustment instructions here http://www.pelicanparts.com/techarticle ... _17-18.jpg

I may have a spare one in my box of D-jet parts at home that I can swap in - I'll look tonight. If not, I'll pull it again, adjust it as above and have a look at the bushing. Where I'd find another one though, I just don't know!

The misfiring is generally when accelerating. If I accelerate very slowly, then it's often OK. If I'm more enthusiastic with the accelerator, then it's more likely to have a problem. That said, I do occasionally get occasional 'blips' whilst at cruising speed as well.

I do have a spare distributor, but the vacuum unit is an advance/retard unit (2 vacuum pipes to the vacuum can), whereas mine only has the advance feature (1 vacuum pipe to the vacuum can). I guess I won't be able to use that one.

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Bingo! My box of spare parts has liberated 2 spare throttle bodies fitted with throttle valve sensors.

One of the throttle bodies has two vacuum ports on it, and the other one only has one. I guess the one with two vacuum ports is designed for the distributor with two vacuum ports?

I'll clean up the one with one vacuum port, set it as per the instructions above, report back when I've fitted it, and let you know if it solves the problem....

One of the throttle bodies has two vacuum ports on it, and the other one only has one. I guess the one with two vacuum ports is designed for the distributor with two vacuum ports?

I'll clean up the one with one vacuum port, set it as per the instructions above, report back when I've fitted it, and let you know if it solves the problem....

- raygreenwood

- Posts: 11910

- Joined: Wed Jan 22, 2003 12:01 am

That tells me a good bit. If the misfiring seems to happen...mainly when you "know" that the throttle plate is in "forward" motion moving through its arc.....its usually one of a couple of things

(a) Due to wear, bending or slop in the "D" bushing....the forked contact is vibrating from hard movement and bouncing off of the forward pin. This can also be caused by heavily worn throttle shaft bores...but thats very rare to be worn that much.

(b) Skipping tracks or circuit traces as the wiper arms go through their arc. This can be due to worn or slightly bent wiper arms that do not have enough tension on them to keep them firmly in contact with the circuit board.....or...if you seea nice worn shiny line in the arc of the circuit board....its rough edges on that worn lines that are catching on a slightly bent wiper arm causing chattering across the board.

(c) This is also very common....wiring issues anywhere in the 25 wire harness. Poor contact at any given area can be vibration sensitive, Its one of the hallmarks of the D-jet connector. It may be rock solid at one "harmonic" and only seem to have issues when the vibration level gets to a certain point like under heavy load or at a specific rpm.

One of the main plugs that has problems with this is the three wire plug on the dizzy. Run the car at a constant 2000 rpm and jiggle the plug. Do the injectors and CHT and TVS as well. See if that replicates the fault.

The reason why YOU might have to do the jiggling while at rpm...is because sitting still you cannot exactly replicate the rocking of the engine while driving.

Yes...its possible that it could be over or under enrichming. It may just be off in fuel mixture...meaning its running lean while advance is high under acceleration.....but from your description I think not.

A quick way to find out if its poor enrichment under load is to bump the fule pressure up about 2 psi. It will make it richer than necessary down low...but if it gets rid of the problem or makles it better..chanes are something has either changed with your CHT or MpS.

Did you check your mps for vacuum leaks? Ray

(a) Due to wear, bending or slop in the "D" bushing....the forked contact is vibrating from hard movement and bouncing off of the forward pin. This can also be caused by heavily worn throttle shaft bores...but thats very rare to be worn that much.

(b) Skipping tracks or circuit traces as the wiper arms go through their arc. This can be due to worn or slightly bent wiper arms that do not have enough tension on them to keep them firmly in contact with the circuit board.....or...if you seea nice worn shiny line in the arc of the circuit board....its rough edges on that worn lines that are catching on a slightly bent wiper arm causing chattering across the board.

(c) This is also very common....wiring issues anywhere in the 25 wire harness. Poor contact at any given area can be vibration sensitive, Its one of the hallmarks of the D-jet connector. It may be rock solid at one "harmonic" and only seem to have issues when the vibration level gets to a certain point like under heavy load or at a specific rpm.

One of the main plugs that has problems with this is the three wire plug on the dizzy. Run the car at a constant 2000 rpm and jiggle the plug. Do the injectors and CHT and TVS as well. See if that replicates the fault.

The reason why YOU might have to do the jiggling while at rpm...is because sitting still you cannot exactly replicate the rocking of the engine while driving.

Yes...its possible that it could be over or under enrichming. It may just be off in fuel mixture...meaning its running lean while advance is high under acceleration.....but from your description I think not.

A quick way to find out if its poor enrichment under load is to bump the fule pressure up about 2 psi. It will make it richer than necessary down low...but if it gets rid of the problem or makles it better..chanes are something has either changed with your CHT or MpS.

Did you check your mps for vacuum leaks? Ray

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Thanks again Ray,

I don't think it's a problem with the MPS (I seem to remember checking whether it would hold vacuum), but again, I have a couple of spare ones that I can swap in if need be (the previous owner of the car seemed to build up quite a large supply of spare parts!). I've even got a spare ECU and harness if it comes down to that! Apart from this stutter, the car seems to run fine: it starts and idles perfectly, can reach 80-90mph easily (on my private test track of course!), and the gas mileage is fine.

I don't think it's a connector problem. I've done lots of 'wiggling' of all of them, and cleaned them with contact cleaner when I had the idle problem which turned out to be an HT lead interference problem. That said there's no harm in going through everything again.

I'll change over the throttle body and TVS for a spare one first, having calibrated it, and see if that makes a difference (when I get the time over the next few days......)

Here's a 'free' pic of the car in question:

(Sorry about the 'odd' wheels at the moment )

)

I don't think it's a problem with the MPS (I seem to remember checking whether it would hold vacuum), but again, I have a couple of spare ones that I can swap in if need be (the previous owner of the car seemed to build up quite a large supply of spare parts!). I've even got a spare ECU and harness if it comes down to that! Apart from this stutter, the car seems to run fine: it starts and idles perfectly, can reach 80-90mph easily (on my private test track of course!), and the gas mileage is fine.

I don't think it's a connector problem. I've done lots of 'wiggling' of all of them, and cleaned them with contact cleaner when I had the idle problem which turned out to be an HT lead interference problem. That said there's no harm in going through everything again.

I'll change over the throttle body and TVS for a spare one first, having calibrated it, and see if that makes a difference (when I get the time over the next few days......)

Here's a 'free' pic of the car in question:

(Sorry about the 'odd' wheels at the moment

- Piledriver

- Moderator

- Posts: 22842

- Joined: Sat Feb 16, 2002 12:01 am

#1 rule of diagnostics---

NEVER, EVER swap ANY parts until ALL the basics are done. (This way madness lies)

Absolutely. No. Vacuum. Leaks.

Ignition//tune up solid

Fuel pressure right and rock steady

Known good injectors

Clean grounds. Perfectly clean.

The absolute first things I would do start with 2 things I learned from Ray:

0)Replace the injector seals with the fat, green Viton Bosch CIS injector orings (Fit any CIS Golf and loads of other cars)

Like...Now, before doing anything else... #1 most likely thing basically certain to be messed up.

Vacuum leaks, like children, can cause insanity.

Even when very small...

1)Replace the plugs with NGK 1263s.

Milk of Magnesia as anti-seize. (Jakes trick---works very well)

2)Flow test the injectors and verify spray pattern, or (Best plan)

send a spare set out to be cleaned and tested and swap in when done.

3)Unless you absolutely KNOW the PO did it recently (and when) replace ALL your rubber fuel lines ASAP. This includes under the fuel tank.

The rest of the plumbing can be checked visually/by feel and have a reasonable chance of seeing issues.

They make lovely leak finding tools-- called "smoke machines" over here, basically produces a thick non-toxic smoke (With UV tracer) than gets pumped into .. things to find leaks... Beats the heck out of any other method if it can be found and afforded.

(These are very expensive, something a shop would own, sadly not something to rent)

NEVER, EVER swap ANY parts until ALL the basics are done. (This way madness lies)

Absolutely. No. Vacuum. Leaks.

Ignition//tune up solid

Fuel pressure right and rock steady

Known good injectors

Clean grounds. Perfectly clean.

The absolute first things I would do start with 2 things I learned from Ray:

0)Replace the injector seals with the fat, green Viton Bosch CIS injector orings (Fit any CIS Golf and loads of other cars)

Like...Now, before doing anything else... #1 most likely thing basically certain to be messed up.

Vacuum leaks, like children, can cause insanity.

Even when very small...

1)Replace the plugs with NGK 1263s.

Milk of Magnesia as anti-seize. (Jakes trick---works very well)

2)Flow test the injectors and verify spray pattern, or (Best plan)

send a spare set out to be cleaned and tested and swap in when done.

3)Unless you absolutely KNOW the PO did it recently (and when) replace ALL your rubber fuel lines ASAP. This includes under the fuel tank.

The rest of the plumbing can be checked visually/by feel and have a reasonable chance of seeing issues.

They make lovely leak finding tools-- called "smoke machines" over here, basically produces a thick non-toxic smoke (With UV tracer) than gets pumped into .. things to find leaks... Beats the heck out of any other method if it can be found and afforded.

(These are very expensive, something a shop would own, sadly not something to rent)

Addendum to Newtons first law:

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

zero vehicles on jackstands, square gets a fresh 090 and 1911, cabby gets a blower.

EZ3.6 Vanagon after that.(mounted, needs everything finished) then Creamsicle.

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Re: D-Jet 'progression problems'

Update!

I still plan to do a full tune-up, but whilst waiting for the parts to arrive, I thought I'd still swap in a spare Throttle Valve Switch (I know you shouldn't really do this, but since I had a spare, I couldn't resist! I knew that I could always put the original one back if need be!).

I've followed all your detailed adjustment instructions Ray, and now I understand why you call it a TVS rather than a TPS - it doesn't measure the throttle position at all! (Except perhaps at Idle and WOT). I do like that 'eureka' moment, when you understand how a part works!

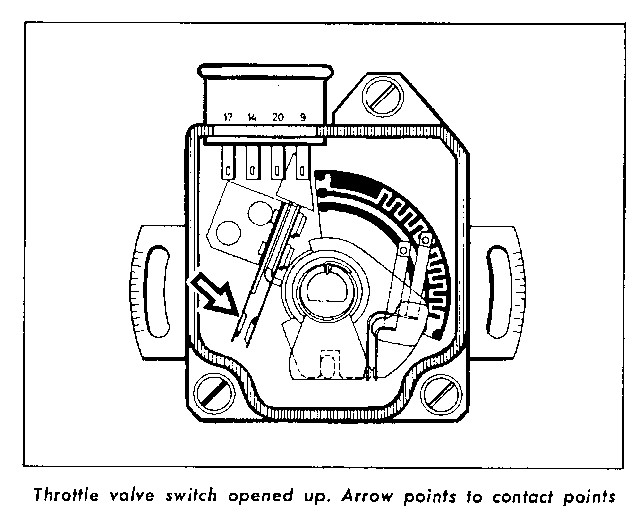

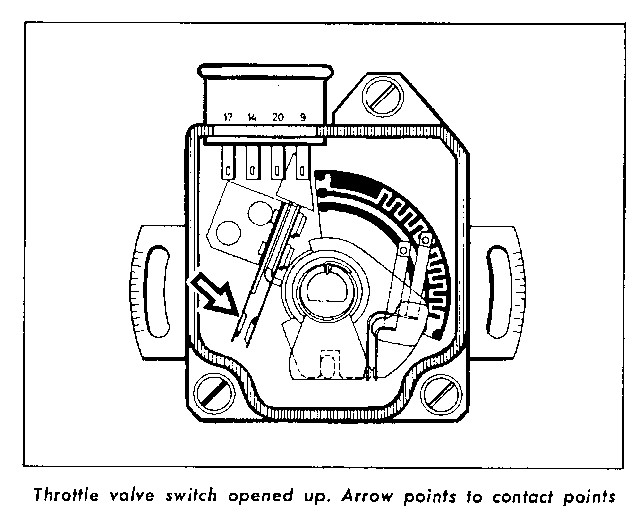

Problem #1 though is that both my spare ones are 4 pin, whereas the one in the car is 5 pin. They're also a completely different design. The one in the car is as you describe, looking like this:

The spare ones I have look like this:

(Pics taken from Google). Problem #2 is that my 4 pin ones however have wires soldered between the pins and the terminals within the switch, so the 4 pin socket is not replaceable. Note that this type only has the 'forward' switch, and no backward one, with the exception of the idle circuit switch, which in mine is screwed in place. I had to adjust this last after following your instructions for setting up the 'forward' switch.

Now I don't really like bodging things, but in this case, I cut off the 'ends' of the socket, therefore enabling my 5 pin connector (of which only 4 pins are connected) to fit.

So? Has it made a difference? I've not yet tested it on a long run, but from driving around my block, it does seem to have solved the problem! Throttle response seems sharper, and it doesn't seem to 'stutter' any more on acceleration. It's not perfectly smooth, so there's still scope for further tuning to get the best out of it, but it seems a lot better! Thank you!

I still plan to do a full tune-up, but whilst waiting for the parts to arrive, I thought I'd still swap in a spare Throttle Valve Switch (I know you shouldn't really do this, but since I had a spare, I couldn't resist! I knew that I could always put the original one back if need be!).

I've followed all your detailed adjustment instructions Ray, and now I understand why you call it a TVS rather than a TPS - it doesn't measure the throttle position at all! (Except perhaps at Idle and WOT). I do like that 'eureka' moment, when you understand how a part works!

Problem #1 though is that both my spare ones are 4 pin, whereas the one in the car is 5 pin. They're also a completely different design. The one in the car is as you describe, looking like this:

The spare ones I have look like this:

(Pics taken from Google). Problem #2 is that my 4 pin ones however have wires soldered between the pins and the terminals within the switch, so the 4 pin socket is not replaceable. Note that this type only has the 'forward' switch, and no backward one, with the exception of the idle circuit switch, which in mine is screwed in place. I had to adjust this last after following your instructions for setting up the 'forward' switch.

Now I don't really like bodging things, but in this case, I cut off the 'ends' of the socket, therefore enabling my 5 pin connector (of which only 4 pins are connected) to fit.

So? Has it made a difference? I've not yet tested it on a long run, but from driving around my block, it does seem to have solved the problem! Throttle response seems sharper, and it doesn't seem to 'stutter' any more on acceleration. It's not perfectly smooth, so there's still scope for further tuning to get the best out of it, but it seems a lot better! Thank you!

- raygreenwood

- Posts: 11910

- Joined: Wed Jan 22, 2003 12:01 am

Re: D-Jet 'progression problems'

So just to be sure you actually just trimmed the ends of the plastic plug....you din't cut any wires right? That fine. You can also take a plastic or metal pick or jewelers screwdriver and remove the terminals from the plug and them slip them into a four or five pin plug.....or.....and most people do not know this......many of the 4 and five pin late model switches ...like that one you have in teh color picture are either identical or so close that they can be swapped.

By this I mean they have the same part # of circuit board inside. Several of teh four pin models have all of the same circuit and board inside...they just utilize one less function....usually fuel cut-off or an extra ground. You can actually grab the female portion of teh four or five pin socket on the TVS with a pair of pliers..and twist it....and it snaps out of its mounting groove. The "fingers" from the socket are spring loaded to land on the proper parts of the circuit board. You can then snap back in...the four or five pin plug you need....effectively factory converting the switch.

The line drawing black and white switch will not do for your car. It is early 411 or type 3. But...they are valuable enough to trade with or sell....so don't throw them away. With certain harnesses, they may do basic functions...but usually only with the early D-jet that had a presure switch outside of the MPS.

The really important part about the TVS is getting it adjusted correctly. the books are almost all either incorrect, incomplete....and do not show you how to check it once it is adjusted. Let me know if you need help and can e-mail pictures of how to adjust. Ray

By this I mean they have the same part # of circuit board inside. Several of teh four pin models have all of the same circuit and board inside...they just utilize one less function....usually fuel cut-off or an extra ground. You can actually grab the female portion of teh four or five pin socket on the TVS with a pair of pliers..and twist it....and it snaps out of its mounting groove. The "fingers" from the socket are spring loaded to land on the proper parts of the circuit board. You can then snap back in...the four or five pin plug you need....effectively factory converting the switch.

The line drawing black and white switch will not do for your car. It is early 411 or type 3. But...they are valuable enough to trade with or sell....so don't throw them away. With certain harnesses, they may do basic functions...but usually only with the early D-jet that had a presure switch outside of the MPS.

The really important part about the TVS is getting it adjusted correctly. the books are almost all either incorrect, incomplete....and do not show you how to check it once it is adjusted. Let me know if you need help and can e-mail pictures of how to adjust. Ray

- Piledriver

- Moderator

- Posts: 22842

- Joined: Sat Feb 16, 2002 12:01 am

Re: D-Jet 'progression problems'

The D-jet "TPS" is more of a motion sensor than a TPS... works along the lines of an accelerator pump.

Motion is sensed by the on/off changes across the contacts, the more motion, the more fuel.

Motion is sensed by the on/off changes across the contacts, the more motion, the more fuel.

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Re: D-Jet 'progression problems'

I didn't cut any wires - I just cut the plastic at end of each end of the socket, so the 5 pin plug would fit. I also followed your adjustment instructions in previous threads that you've written on the subject, so I hope that it's all done properly....raygreenwood wrote:So just to be sure you actually just trimmed the ends of the plastic plug....you din't cut any wires right? That fine. You can also take a plastic or metal pick or jewelers screwdriver and remove the terminals from the plug and them slip them into a four or five pin plug.....or.....and most people do not know this......many of the 4 and five pin late model switches ...like that one you have in teh color picture are either identical or so close that they can be swapped.

By this I mean they have the same part # of circuit board inside. Several of teh four pin models have all of the same circuit and board inside...they just utilize one less function....usually fuel cut-off or an extra ground. You can actually grab the female portion of teh four or five pin socket on the TVS with a pair of pliers..and twist it....and it snaps out of its mounting groove. The "fingers" from the socket are spring loaded to land on the proper parts of the circuit board. You can then snap back in...the four or five pin plug you need....effectively factory converting the switch.

The line drawing black and white switch will not do for your car. It is early 411 or type 3. But...they are valuable enough to trade with or sell....so don't throw them away. With certain harnesses, they may do basic functions...but usually only with the early D-jet that had a presure switch outside of the MPS.

The really important part about the TVS is getting it adjusted correctly. the books are almost all either incorrect, incomplete....and do not show you how to check it once it is adjusted. Let me know if you need help and can e-mail pictures of how to adjust. Ray

You say that the 'line drawing black and white switch will not do', but this is what I have now fitted, and the car seems to drive a lot better than with the 'correct' 5 pin late one! What are the consequences of having this 'incorrect' one fitted? I guess it doesn't have the switch to tell the ECU that the car is decelerating, but is this really needed - I don't really want the 'fuel cut-off' circuit. What does the secondary pressure switch do on 411's/ Type 3's? I don't really want to put back the original switch now, and get the same problems all over again!

I'll have a look at my other 4 pin spare TVS to see if it's a late or early type this evening. My suspicions are that it's early though....

Thanks again

Rhodri

- raygreenwood

- Posts: 11910

- Joined: Wed Jan 22, 2003 12:01 am

Re: D-Jet 'progression problems'

The early switches "can" work....but generally do not work as smoothly. They simply have a very rough switch and a little less resolution on the wiper contacts.

If its giving you acceleration and TB closed signals it will work. 8 out of 10 times, problems with the newer switches have to do with adjustment.

If you have a good idea of how the switches work...they are very easy to adjust. The "act" of adjusting is not the issue. The issue..... with later switches is that some of them depending on when they were made have a bit more or less slop in the floating fork switch attached to the D-bushing. After adjusting....that needs to be inspected and readjusted for if necessary. What you are looking for and the fact that this needs to be done is what is missing from most manuals.

I'm not saying you have not done that. Just saying that if the switch is in good shape and the harness/wires are also and everything else is fine.....the TVS should work well.

That being said...some late builds of the TVS...had enough slop that I had to modify them to get them to adjust properly.

The fuel shut-off....ib my experience....is redundent. If you have a decel valve and vacuum retard on your distributor...the fuel cut-off is redundent. All three of those parts and the factory PCV working in concert (which means with no timing relation to each other).....can cause this bucking/mis-firing.

You can cut it off simply by pulling its wire out of the plug...but be careful in some odd cases depending on the harness build you might miss an importnat ground this way. I wrote a long spiel in the Samba a while back about the ground paths of four and five pin switches. usually I can look at your harness and very quickly find out if pulling the wire for the fuel shut-off is a problem. The five pin switches had an extra ground. Ray

If its giving you acceleration and TB closed signals it will work. 8 out of 10 times, problems with the newer switches have to do with adjustment.

If you have a good idea of how the switches work...they are very easy to adjust. The "act" of adjusting is not the issue. The issue..... with later switches is that some of them depending on when they were made have a bit more or less slop in the floating fork switch attached to the D-bushing. After adjusting....that needs to be inspected and readjusted for if necessary. What you are looking for and the fact that this needs to be done is what is missing from most manuals.

I'm not saying you have not done that. Just saying that if the switch is in good shape and the harness/wires are also and everything else is fine.....the TVS should work well.

That being said...some late builds of the TVS...had enough slop that I had to modify them to get them to adjust properly.

The fuel shut-off....ib my experience....is redundent. If you have a decel valve and vacuum retard on your distributor...the fuel cut-off is redundent. All three of those parts and the factory PCV working in concert (which means with no timing relation to each other).....can cause this bucking/mis-firing.

You can cut it off simply by pulling its wire out of the plug...but be careful in some odd cases depending on the harness build you might miss an importnat ground this way. I wrote a long spiel in the Samba a while back about the ground paths of four and five pin switches. usually I can look at your harness and very quickly find out if pulling the wire for the fuel shut-off is a problem. The five pin switches had an extra ground. Ray

-

Rhodrich

- Posts: 11

- Joined: Mon Nov 25, 2002 12:01 am

Re: D-Jet 'progression problems'

My car has no vacuum retard on the distributor, and no deceleration valve. I guess that UK spec cars came with a lot less emissions equipment than US ones. Even where emissions equipment came fitted to a car, lots of people junked it: the annual emissions test here for pre August '75 cars is simply that the car does not emit excessive smoke!

I've yet to adjust the 5 pin switch according to your instructions. I might have a go with that this weekend, and put it back on. If it makes things worse again, I'll stick with the 'early' switch that seems to work....

I've yet to adjust the 5 pin switch according to your instructions. I might have a go with that this weekend, and put it back on. If it makes things worse again, I'll stick with the 'early' switch that seems to work....

- MGVWfan

- Posts: 825

- Joined: Fri Jun 11, 2004 9:23 pm

Re: D-Jet 'progression problems'

Got an update, Rhodrich?

BTW, I noticed a minor "trailer hitching" with my D-Jet equipped '73 this summer, even though the traces looked good and the throttle motion sensor was adjusted correctly. Turns out there was a very fine film of something conductive (or maybe not) at certain throttle angles that caused the switch to "fire" very intermittently at those angles...took a 'scope in the passenger's seat hooked to the lines coming out of the accel traces (with a co-pilot reading it) while driving at those throttle angles and with the engine warmed-up to find. Cleaned the traces again, this time with 99% electronics grade isopropanol (leaves no residue) and a chamois tape head cleaner swab, problem gone.

BTW, I noticed a minor "trailer hitching" with my D-Jet equipped '73 this summer, even though the traces looked good and the throttle motion sensor was adjusted correctly. Turns out there was a very fine film of something conductive (or maybe not) at certain throttle angles that caused the switch to "fire" very intermittently at those angles...took a 'scope in the passenger's seat hooked to the lines coming out of the accel traces (with a co-pilot reading it) while driving at those throttle angles and with the engine warmed-up to find. Cleaned the traces again, this time with 99% electronics grade isopropanol (leaves no residue) and a chamois tape head cleaner swab, problem gone.