Above: 1600 Mahle piston with broken con rod. We used too much silicone sealer and the excess got loose inside the case and clogged the oil pickup.

Silicone Sealant - Threat or Menace?

Most VW engine builders will tell you not to use silicone sealants or gasket makers on VW engines, or at least not to overuse them. A little silicone, like a little stupid, goes a long ways.

Above: Sealing up the cylinders sealed this 1600's fate.

One place many builders feel fairly safe using this type of sealant is on the cylinder-to-case fitting. This photo shows exactly how to overdo it, allowing excess silicone debris to get into the oil and in turn restrict flow at the oil pickup tube. And blow an engine. Or two. We blew two. One was our 1600 test engine for the centermount fan housing project, and the other was an 2.2 litre enduro engine we use for LeMons racing.

Above; Our dry sump tank originally had no verticle baffels to stop slosh. but amazingly had a stack of three perforated plates, deck fashion, that kept the oil from surging up and down. We fixed that after early use proved it necessary.

The 2.2 at Road Atlanta when it still had oil pressure

https://www.youtube.com/watch?v=Tng5ReSc2wY

The 2.2 litre was the first to go. It had at least 12 to 14 hours already on it, and those were all on our original non-baffled (and square) 3-gallon dry sump oil tank, which would often allow the engine to briefly starve for oil in a high-G turn. It failed at Road Atlanta on 22 April 2016, knocking when we shut it off.

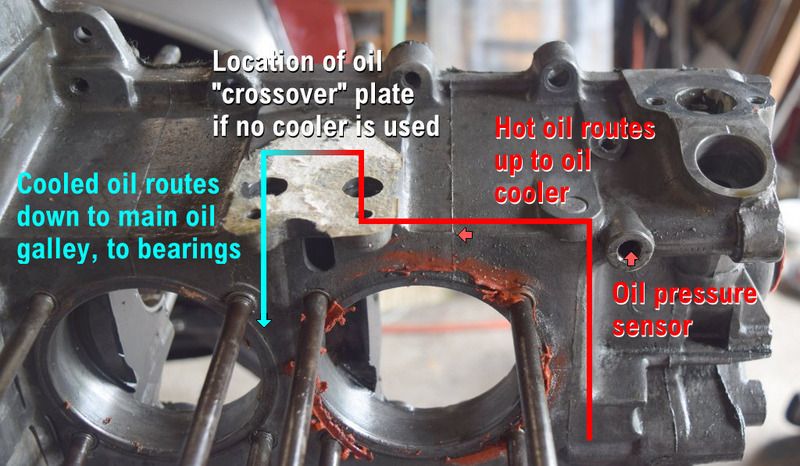

Above; Example of a cross-over plate replacing the stock oil cooler. There are not block-off plates. The oil coming out of the oil cooler outlet port (closest to the pulley end) has to be routed down the inlet port (closest to the flywheel) to feed the bearings.

On disassembly, we found very little silicone in the engine, but there was enough right where it counted. The crossover plate (replacing the stock oil cooler) had beens sealed with a liberal amount of silicone, and a glob of it was partially obstructing the "cooled oil" return passage back into the case. We figured the glob had been there since the case was closed, and slowly contributed to the failed rod beaing, as if the too-frequent unbaffled dry sump sloshes were not enough.

Above: The Ghia at Barber, long telephoto shot, moments before the rod exploded through the case top.

The 1600 didn't make two full laps at Barber on 21 May 2016 before throwing a rod (#1). This engine also had the same red high-temp silicone used on the pushrod tube seals, so it suffered from a double whammy. On teardown, we found the screened oil-suction pickup was well clogged with silicone peelings.

Above: We use an O-ringed Oil Suction kit which pickup flares to about one inch in diameter, and has a nice stainless steel screen. These kits are very effective, but having the larger area of the stock oil strainer would be better.

Above: The Type 1 case oil flow is from the pump to the pressure relief valve, where very cold oil is either routed directly to the main oil gallery and bearings or hot oil is routed to the oil cooler then on to the bearings. We found a lump of silicone partially blocking the crossover plate channel, sure slow death for this one.

No one else to blame here but ourselves for ignoring a basic rule. We've never done it before and we'll never do it again.

FJC