For some time, I thought about making a small budget 100x71 engine, that’s kinda like the poor-man’s version of the future engine I’m building. Here’s the specs:

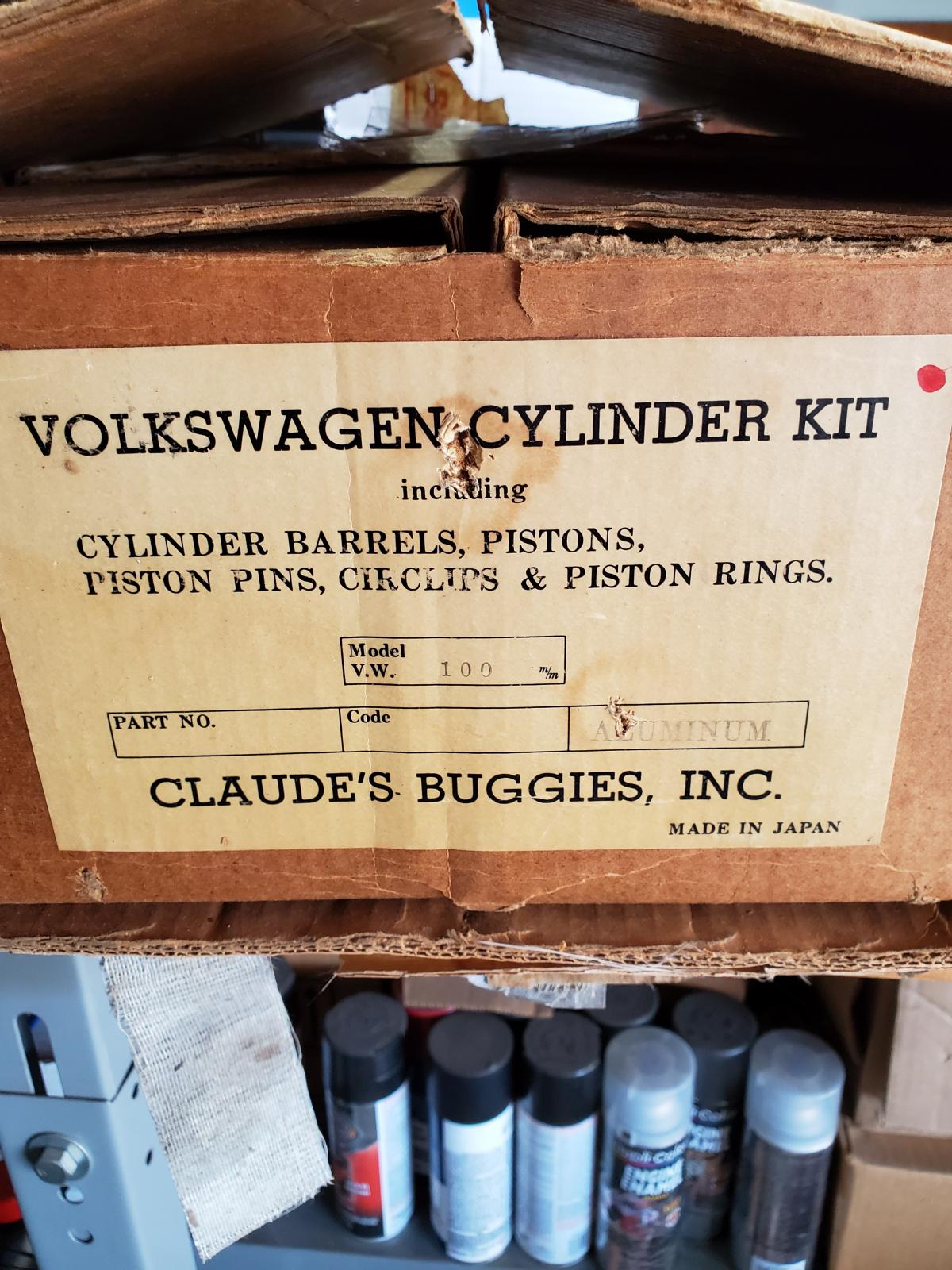

100 NOS Birals - $400

5.7L Hemi pistons - $160

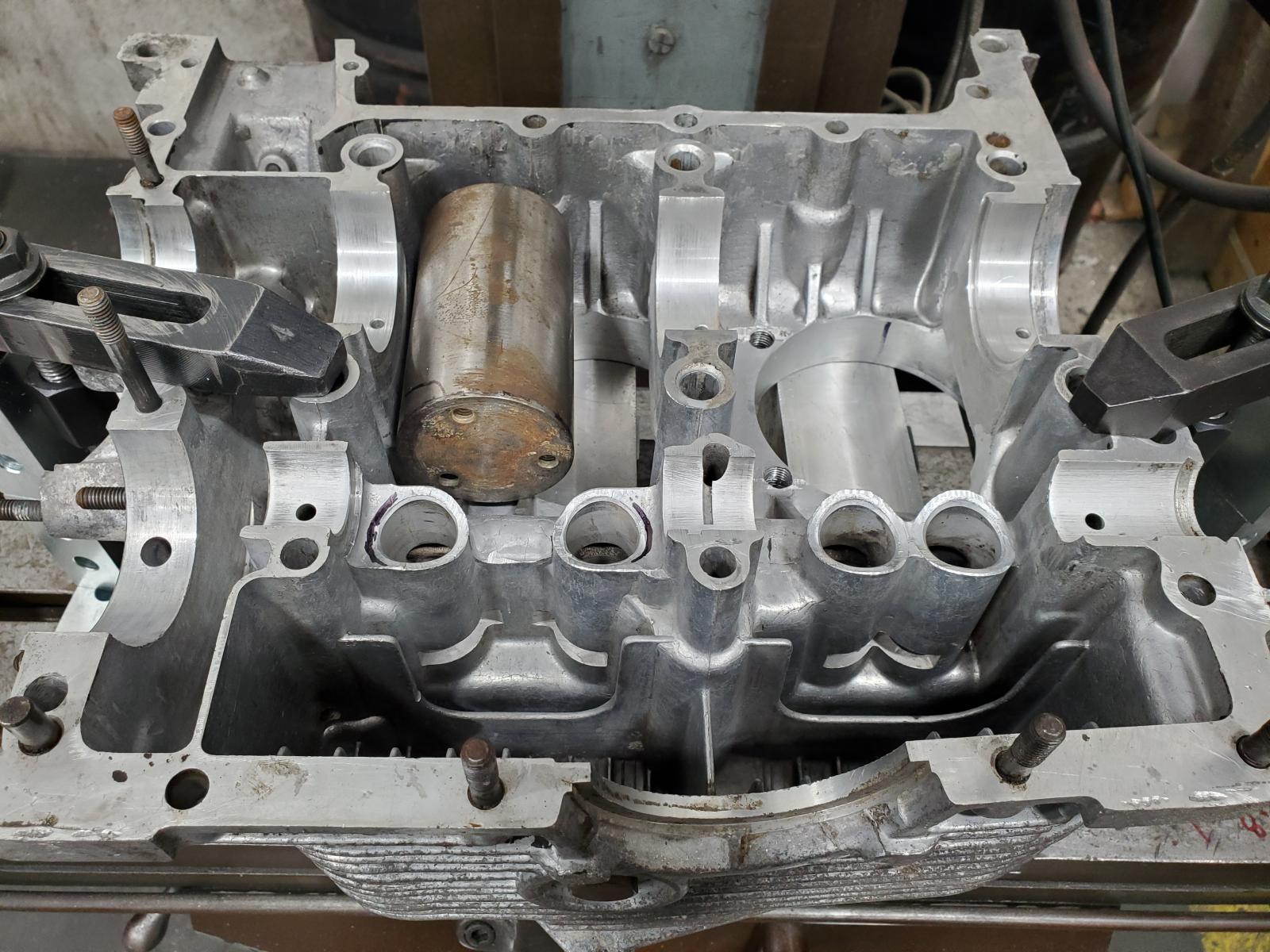

2.0 core - $150

71 regrind, balance - $150

slightly used KEP 200mm flywheel, balanced - $125

AA 5.158” slightly used rods - $200

Eurorace P Cam - $125

AA straight cuts - $125

CB Ultralight lifters - already had for years

Maybe CB dry sump pump - bought a new one for $100

Stock pushrods, tapered, and with comp cams ends installed - $45

Either stock modified rockers and Thorsten adjusters, or some Weiss 1,4 rockers that I have - $800

AA 914 heads, ported by myself, and maybe finished by Anthony Chicca because he has a flow bench and can assemble after. $500 for castings

CSP space saver intakes for IDF - about $100

230HP would be nice. We'll see. It'll depend on my headwork.

Relatively inexpensive build. I'm doing most of the machining.