they should fit just fine I read about that before that they add about 5mm Or so . With the offset of the Phone dial I had to make custom 20mm spacers so I did not rub on anything. SO i am guessing if they add anything i will just use less of a spacer or if i am lucky I will not need spacers anymore.

I am hopping i can get started on the rear the first part January Just have to wait and see I i run into any problems. I think i have all my bases covered..

parts for the rear so far:

thing transmission

944T axle assy

944 alum arms

4pot brembos

996 rear rotors

weld on irs tabs

Time for the Brembo and IRS on the rear ( updates)

-

kombi211

- Posts: 45

- Joined: Thu Oct 11, 2007 11:55 pm

Re: Brembos going on the square now and rear irs upgrade

Well I have started now on the IRS conversion with the 944 alum arm

The parts being used for the rear are as followed:

944 alum trailing arm

944t axle assembles cv to cv

996 rear rotors

944 4 pot brembos

thing trans

modified swing axle spring plates

first i started off by cleaning the arm and painting them up

painted arm with new bushing installed

removed all swing axle tranny and cleaned 40+ years of grease and grim

new weld in brackets

I was going to use 944 trailing arm but i have ran into a little problem already my torsion bar are to short. So for now i will use modified vw spring plates till i can get some upgrade torsion bars ordered and shipped. ( I will post pic on the spring plates once I start on them)

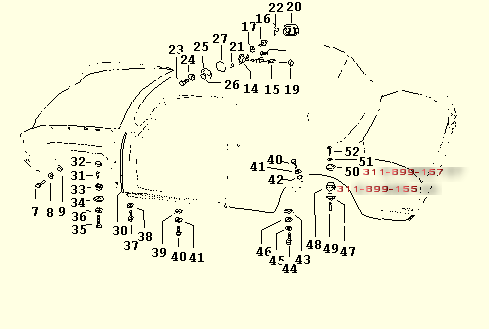

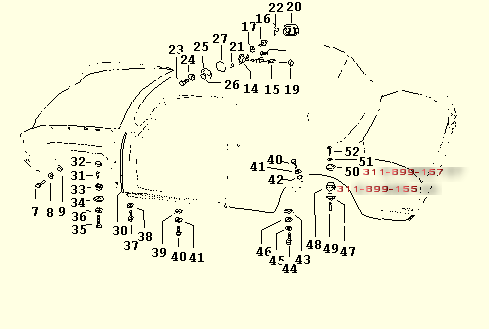

With the Irs conversion its going to be a little different from a Bug conversion. 1st. being the typ3 has a removable sub-frame and the bottom of the torsion tube has a extra support welding on.2ndthe frame horns top half is smaller then a regular Bug tube. this makes the weld in bracket sit a little higher then the tube and not inside like on a bug.

What i done was cut the metal away from the bracket and just folded it up and out of the way to start with that way once the bracket is tacked in place. And its time for final welding i can trim the metal down and hammer it down snug and weld it to the installed brackets. well thats the plan for now. Being like i said the bracket sits out and above the frame horns..

once i have everything where it need to be. Checked and double checked and then tack welded... I will assemble everything to check fitment and alignment of the arms.Hope to do that in the next day or two. After that I am just going to remove the rear sub frame for the clean up and welding....

The parts being used for the rear are as followed:

944 alum trailing arm

944t axle assembles cv to cv

996 rear rotors

944 4 pot brembos

thing trans

modified swing axle spring plates

first i started off by cleaning the arm and painting them up

painted arm with new bushing installed

removed all swing axle tranny and cleaned 40+ years of grease and grim

new weld in brackets

I was going to use 944 trailing arm but i have ran into a little problem already my torsion bar are to short. So for now i will use modified vw spring plates till i can get some upgrade torsion bars ordered and shipped. ( I will post pic on the spring plates once I start on them)

With the Irs conversion its going to be a little different from a Bug conversion. 1st. being the typ3 has a removable sub-frame and the bottom of the torsion tube has a extra support welding on.2ndthe frame horns top half is smaller then a regular Bug tube. this makes the weld in bracket sit a little higher then the tube and not inside like on a bug.

What i done was cut the metal away from the bracket and just folded it up and out of the way to start with that way once the bracket is tacked in place. And its time for final welding i can trim the metal down and hammer it down snug and weld it to the installed brackets. well thats the plan for now. Being like i said the bracket sits out and above the frame horns..

once i have everything where it need to be. Checked and double checked and then tack welded... I will assemble everything to check fitment and alignment of the arms.Hope to do that in the next day or two. After that I am just going to remove the rear sub frame for the clean up and welding....

-

kombi211

- Posts: 45

- Joined: Thu Oct 11, 2007 11:55 pm

Re: Time for the Brembo and IRS on the rear ( updates)

some updates pic's

test fitting arm on modified swing axle spring plate

checking alignment before fully welding everything up

test fitting arm on modified swing axle spring plate

checking alignment before fully welding everything up

- Tom Notch

- Moderator

- Posts: 3332

- Joined: Mon Apr 10, 2000 12:01 am

Re: Time for the Brembo and IRS on the rear ( updates)

I think you may have an issue with wheel alignment if your weld-in pivot brackets are not correctly located.

The pivots need to locate in relation to the spring plate mounting location. If the pivots are too high (which it looks like now), you will have positive camber that can not be adjusted out. They need to locate just like a T1/T3 IRS despite the differences in the "shape" of the torsion housing.

The pivots need to locate in relation to the spring plate mounting location. If the pivots are too high (which it looks like now), you will have positive camber that can not be adjusted out. They need to locate just like a T1/T3 IRS despite the differences in the "shape" of the torsion housing.

Tom

Tom's Old VW Home

DVKK

DSD, dark side disciples

Tom's Old VW Home

DVKK

DSD, dark side disciples

-

kombi211

- Posts: 45

- Joined: Thu Oct 11, 2007 11:55 pm

Re: Time for the Brembo and IRS on the rear ( updates)

yeah with the pic with the bracket.It is just sitting there its not welded in yet hopefully tomorrow i can get it tacked in place so i can pull the sub frame out. To do the final weld up.

-

kombi211

- Posts: 45

- Joined: Thu Oct 11, 2007 11:55 pm

Re: Time for the Brembo and IRS on the rear ( updates)

sub frame out now

cleaned and waiting for treatment of kbs rust blast

I have also rounded up 6 of the 8 nos rubber bushing for the subframe going to see if i can get them all cast in urethane if it doesn't cost to much

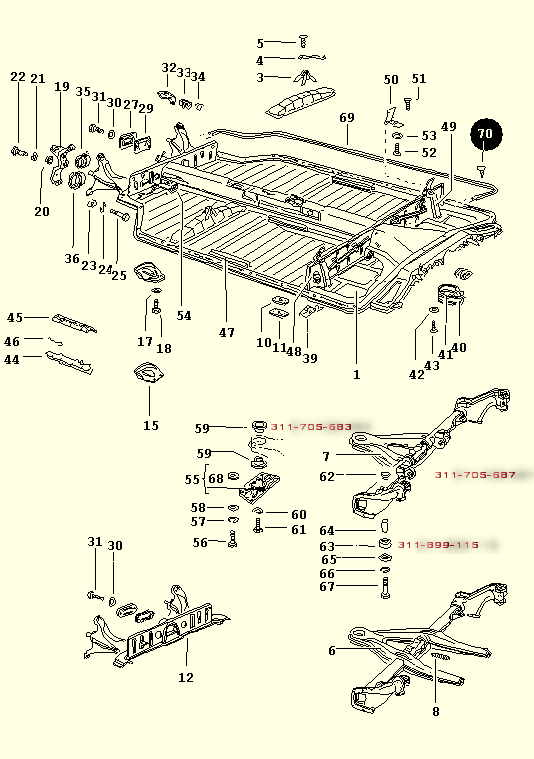

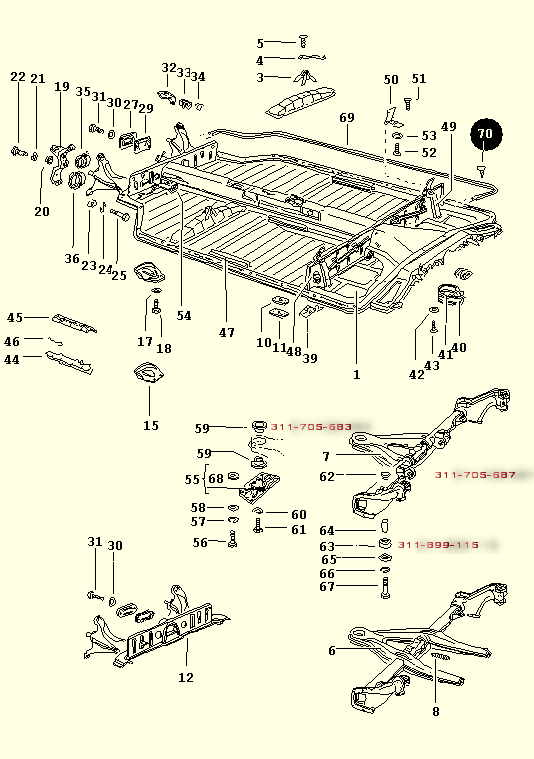

number 62 in pic 1

number 63 in pic 1

cleaned and waiting for treatment of kbs rust blast

I have also rounded up 6 of the 8 nos rubber bushing for the subframe going to see if i can get them all cast in urethane if it doesn't cost to much

number 62 in pic 1

number 63 in pic 1

-

kombi211

- Posts: 45

- Joined: Thu Oct 11, 2007 11:55 pm

Re: Time for the Brembo and IRS on the rear ( updates)

a few more pics, as i progress with the conversion... subframe was treated with rust blast them painted with KBS ruststop. Checking in to have all the subframe mounts cast in urethane. Just to stiffen everything up in prep for the new motor when I start on that part of the project. Hope by next weekend to have everything finish on the IRS part of it so i can pre-assemble the subframe to check the axle and trans fitment. then moving on to some more body work

test fitting left side

cleaning up subframe

40 year old sub frame mount

NOS mount

seen better days these are the last 2 mounts i need to find.Being i have one good one might just have them cast in urethane

subframe painted in KBS ruststop

test fitting left side

cleaning up subframe

40 year old sub frame mount

NOS mount

seen better days these are the last 2 mounts i need to find.Being i have one good one might just have them cast in urethane

subframe painted in KBS ruststop

- supaninja

- Posts: 1658

- Joined: Tue Sep 14, 2010 12:48 pm

Re: Time for the Brembo and IRS on the rear ( updates)

Lookin sweet dude.

'65 notch w/ a squirted type 4

http://supaninjanick.wordpress.com/

'68 "Zombie Response Vehicle" Westy

viewtopic.php?f=14&t=140387

- Angelo Amato

- Posts: 137

- Joined: Sat Feb 24, 2001 12:01 am