Grounding a welding table?

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

Grounding a welding table?

My welding table is on rubber wheels. With MIG everything is cool but with TIG any part of my body touching the table causes me to get shocked. Is the rubber preventing a proper ground?

- Dale M.

- Posts: 1673

- Joined: Mon Oct 05, 2009 8:09 am

Re: Grounding a welding table?

Think its a problem with TIG system and not table.... Do you wear welding gloves?.... Rubber soled shoes....

Problem is you are causing a voltage/current loop between table and TIG torch.... And you are somewhere in loop.... You can try grounding table, but I don't think it will help....

Dale

Problem is you are causing a voltage/current loop between table and TIG torch.... And you are somewhere in loop.... You can try grounding table, but I don't think it will help....

Dale

"Fear The Government That Wants To Take Your Guns" - Thomas Jefferson

1970 "Kellison Sand Piper Roadster"

1970 "Kellison Sand Piper Roadster"

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

Re: Grounding a welding table?

Yes, gloves and rubber soled shoes. What kind of problem ideas what to check. It's a Miller synchrowave 250 virtually new.

-

Chris4747

- Posts: 171

- Joined: Mon Apr 09, 2012 3:02 pm

Re: Grounding a welding table?

Are you using a foot peddal or trigger on the torch ?are you grounding to the table or to the actual work? you may have a bad ground lead .If you try to ark to far away from your work and you are resting on the table it will bite you every time .If the ground lead is bad and you jostle the lead around it will bite you .Even a tiny hole in gloves and the current will find its way to you .the wheels wont affect the table at all as the ground will be hooked directly to the metal table or the work in progress(what you are welding on)

Also if the tig torch has any pin holes or cuts in the rubber on the handle it will bite even through the gloves.

Also if the tig torch has any pin holes or cuts in the rubber on the handle it will bite even through the gloves.

instant gratification by hard work and determination granted by GODS hands

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

Re: Grounding a welding table?

Thanks - I have been grounding the table as that has worked well for the MIG. I am using the foot pedal. My problem may be arking too far away since I'm just learning TIG. My confusion is that if the wheels are rubber what's grounding the table? Even if the ground from the welder is attached to the work or the table the table is still mounted on rubber?

-

Chris4747

- Posts: 171

- Joined: Mon Apr 09, 2012 3:02 pm

Re: Grounding a welding table?

This is from American welding Society

Welding Machine Ground

Welding machines that utilize a flexible cord and plug arrangement or those that are permanently wired into an electrical supply system contain a grounding conductor. The grounding conductor connects the metal enclosure of the welding machine to ground. If we could trace the grounding wire back through the electrical power distribution system we would find that it is connected to earth, and usually through a metal rod driven into the earth.

Grounding and Arc Welding Safety

The purpose of connecting the equipment enclosure to ground is to ensure that the metal enclosure of the welding machine and ground is at the same potential. When they are at the same potential, a person will not experience an electrical shock when touching the two points. Grounding the enclosure also limits the voltage on the enclosure in the event that insulation should fail within the equipment.

The current carrying capability of the grounding conductor is coordinated with the overcurrent device of the electrical supply system. The coordination of ampacity allows the grounding conductor to remain intact even if there is an electrical fault within the welding machine.

Some welding machines may have a double insulated design. In this case, a grounding conductor connection is not required. This type of welding machine relies on extra insulation to protect the user from shock. When double insulation is present it is identified by a "box within a box" symbol on the rating plate.

Grounding and Arc Welding Safety

For small welding machines that utilize a plug on the end of a power cord, the grounding conductor connection is made automatically when the welding machine is plugged into the receptacle. The grounding pin of the plug makes a connection within the receptacle. The use of adapters that effectively remove the grounding pin connection at the plug is not recommended. Furthermore, do not cut off or remove the grounding pin from the plug. All safety benefit of the grounding conductor is lost without the connection.

Grounding and Arc Welding Safety

Receptacle circuit testers will easily check the continuity of the grounding conductor. Receptacle circuit testers for 120-volt circuits are available at electrical supply or hardware stores; these inexpensive test devices plug into an electrical outlet. Indicator lights show whether the grounding circuit is available at the outlet, as well as other circuit tests. If the test device shows the absence of a ground connection or other circuit problem, call a qualified electrician for assistance. This is a simple test and should be done periodically. Consult with a qualified electrician to test circuits greater than 120 volts.

Grounding and Arc Welding Safety

Workpiece Ground

The welding circuit consists of all conductive material through which the welding current is intended to flow. Welding current flows through the welding machine terminals, welding cables, workpiece connection, gun, torch, electrode holder and workpiece. The welding circuit is not connected to ground within the welding machine, but is isolated from ground. How do we ground the welding circuit?

According to ANSI Z49.1, "Safety in Welding, Cutting and Allied Processes," the workpiece or the metal table that the workpiece rests upon must be grounded. We must connect the workpiece or work table to a suitable ground, such as a metal building frame. The ground connection should be independent or separate from the welding circuit connection.

Grounding and Arc Welding Safety

Grounding the workpiece has similar benefit to grounding the welding machine enclosure. When the workpiece is grounded, it is at the same potential as other grounded objects in the area. In the event of insulation failure in the arc welding machine or other equipment, the voltage between the workpiece and ground will be limited. Note that it is possible to have an ungrounded workpiece, but this requires the approval of a qualified person.

The Workpiece Connection is not a Ground Clamp

"Ground clamp" and "ground lead" are common terms used by many welders. The workpiece is connected to a welding cable typically by means of a spring loaded clamp or screw clamp. Unfortunately, a workpiece connection is often incorrectly called a "ground clamp" by many welders and the workpiece lead is incorrectly called "ground lead." The welding cable does not bring a ground connection to the workpiece. The ground connection is separate from the workpiece connection.

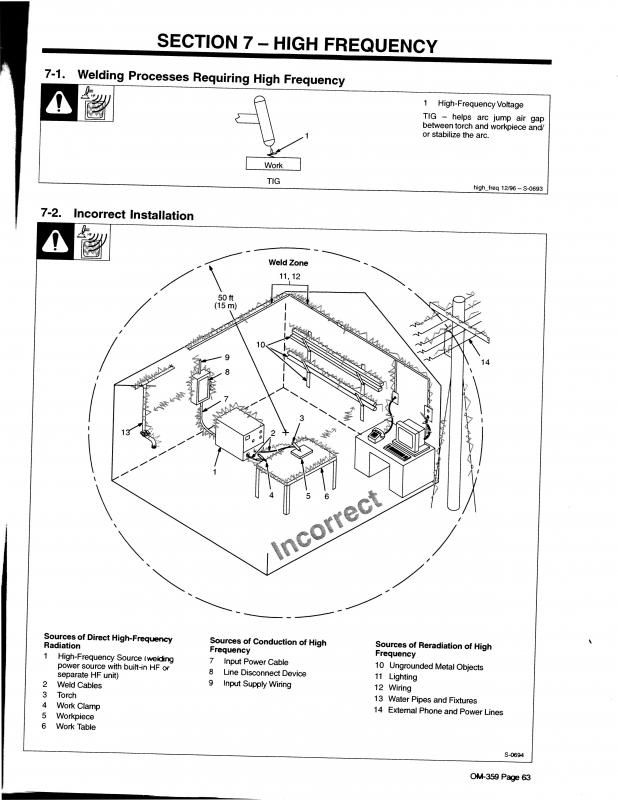

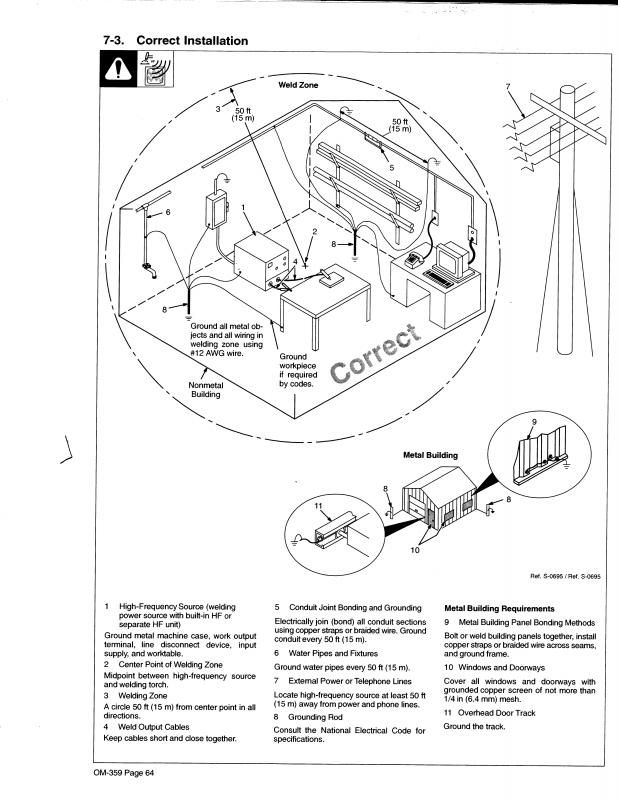

High Frequency Ground

Some welding machines utilize starting and stabilizing circuits that contain a high frequency voltage. This is common on Tungsten Inert Gas (TIG) welding machines. The high frequency voltage may have frequency components that extend into the megahertz region. In contrast, the welding voltage may be as low as 60 Hertz.

High frequency signals have a tendency to radiate away from the welding area. These signals may cause interference with nearby radio and television reception or other electrical equipment. One method to minimize the radiation of high frequency signals is to ground the welding circuit. The welding machine instruction manual will have specific instructions on how to ground the welding circuit and components in the surrounding area to minimize the radiation effect.

Portable and Vehicle Mounted Welding Generator Grounding

Portable and vehicle mounted arc welding generators often have the capability to supply 120 and 240 volt auxiliary power. These generators are used in remote locations away from an electrical power distribution system. A convenient earth ground is not usually available for connection. Should the generator frame be grounded?

The rules for grounding depend on the specific use and design of the auxiliary power generator. Most applications fall into one of the two categories summarized below:

1. If all of these requirements are met, then it is not required to ground the generator frame:

The generator is mounted to truck or trailer

The auxiliary power is taken from receptacles on the generator using a cord and plug arrangement

The receptacles have a grounding pin

The frame of the generator is bonded, or electrically connected, to the truck or trailer frame

2. If either of these conditions are met, then the generator frame must be grounded:

The generator is connected to a premises wiring system. For example, to supply power to a house during a blackout.

The auxiliary power is hard wired into the generator without the use of cords and plugs.

The summary above does not go into details and the reader is urged to consult their local electrical codes and ANSI/NFPA 70, "National Electrical Code" for the specifics.

Extension Cord Grounds

Extension cords should be periodically tested for ground continuity. Extension cords lead a rough life while lying on the ground; they are under foot and prone to damage. The use of a receptacle circuit tester will confirm that all of the connections are intact within the cord, plug and receptacle.

Welding Circuit Shock Hazards

Utilizing proper grounding in the welding environment is a good practice, but it does not remove all possibility of electrical shock. The welding circuit is energized by welding voltage. A person will receive a shock if they become the electrical path across the welding circuit. Precautions must be taken to insulate the welder from the welding circuit. Use dry insulating gloves and other insulating means. Also maintain insulation on weld cables, electrode holders, guns and torches to provide protection.

Similarly, electric shock originating from the electrical supply system can be prevented. Proper maintenance of electrical equipment and extension cords will insulate the welder from electrical sources.

Information Sources

American Welding Society, ANSI Z49.1:2005 "Safety in Welding, Cutting, and Allied Processes."

National Fire Protection Association, NFPA 70, "National Electrical Code", 2005.

American Welding Society, Safety and Health Fact Sheet No. 29, "Grounding of Portable and Vehicle Mounted Welding Generators", July 2004.

American Welding Society, AWS A3.0-2001, "Standard Welding Terms and Definitions."

Welding Machine Ground

Welding machines that utilize a flexible cord and plug arrangement or those that are permanently wired into an electrical supply system contain a grounding conductor. The grounding conductor connects the metal enclosure of the welding machine to ground. If we could trace the grounding wire back through the electrical power distribution system we would find that it is connected to earth, and usually through a metal rod driven into the earth.

Grounding and Arc Welding Safety

The purpose of connecting the equipment enclosure to ground is to ensure that the metal enclosure of the welding machine and ground is at the same potential. When they are at the same potential, a person will not experience an electrical shock when touching the two points. Grounding the enclosure also limits the voltage on the enclosure in the event that insulation should fail within the equipment.

The current carrying capability of the grounding conductor is coordinated with the overcurrent device of the electrical supply system. The coordination of ampacity allows the grounding conductor to remain intact even if there is an electrical fault within the welding machine.

Some welding machines may have a double insulated design. In this case, a grounding conductor connection is not required. This type of welding machine relies on extra insulation to protect the user from shock. When double insulation is present it is identified by a "box within a box" symbol on the rating plate.

Grounding and Arc Welding Safety

For small welding machines that utilize a plug on the end of a power cord, the grounding conductor connection is made automatically when the welding machine is plugged into the receptacle. The grounding pin of the plug makes a connection within the receptacle. The use of adapters that effectively remove the grounding pin connection at the plug is not recommended. Furthermore, do not cut off or remove the grounding pin from the plug. All safety benefit of the grounding conductor is lost without the connection.

Grounding and Arc Welding Safety

Receptacle circuit testers will easily check the continuity of the grounding conductor. Receptacle circuit testers for 120-volt circuits are available at electrical supply or hardware stores; these inexpensive test devices plug into an electrical outlet. Indicator lights show whether the grounding circuit is available at the outlet, as well as other circuit tests. If the test device shows the absence of a ground connection or other circuit problem, call a qualified electrician for assistance. This is a simple test and should be done periodically. Consult with a qualified electrician to test circuits greater than 120 volts.

Grounding and Arc Welding Safety

Workpiece Ground

The welding circuit consists of all conductive material through which the welding current is intended to flow. Welding current flows through the welding machine terminals, welding cables, workpiece connection, gun, torch, electrode holder and workpiece. The welding circuit is not connected to ground within the welding machine, but is isolated from ground. How do we ground the welding circuit?

According to ANSI Z49.1, "Safety in Welding, Cutting and Allied Processes," the workpiece or the metal table that the workpiece rests upon must be grounded. We must connect the workpiece or work table to a suitable ground, such as a metal building frame. The ground connection should be independent or separate from the welding circuit connection.

Grounding and Arc Welding Safety

Grounding the workpiece has similar benefit to grounding the welding machine enclosure. When the workpiece is grounded, it is at the same potential as other grounded objects in the area. In the event of insulation failure in the arc welding machine or other equipment, the voltage between the workpiece and ground will be limited. Note that it is possible to have an ungrounded workpiece, but this requires the approval of a qualified person.

The Workpiece Connection is not a Ground Clamp

"Ground clamp" and "ground lead" are common terms used by many welders. The workpiece is connected to a welding cable typically by means of a spring loaded clamp or screw clamp. Unfortunately, a workpiece connection is often incorrectly called a "ground clamp" by many welders and the workpiece lead is incorrectly called "ground lead." The welding cable does not bring a ground connection to the workpiece. The ground connection is separate from the workpiece connection.

High Frequency Ground

Some welding machines utilize starting and stabilizing circuits that contain a high frequency voltage. This is common on Tungsten Inert Gas (TIG) welding machines. The high frequency voltage may have frequency components that extend into the megahertz region. In contrast, the welding voltage may be as low as 60 Hertz.

High frequency signals have a tendency to radiate away from the welding area. These signals may cause interference with nearby radio and television reception or other electrical equipment. One method to minimize the radiation of high frequency signals is to ground the welding circuit. The welding machine instruction manual will have specific instructions on how to ground the welding circuit and components in the surrounding area to minimize the radiation effect.

Portable and Vehicle Mounted Welding Generator Grounding

Portable and vehicle mounted arc welding generators often have the capability to supply 120 and 240 volt auxiliary power. These generators are used in remote locations away from an electrical power distribution system. A convenient earth ground is not usually available for connection. Should the generator frame be grounded?

The rules for grounding depend on the specific use and design of the auxiliary power generator. Most applications fall into one of the two categories summarized below:

1. If all of these requirements are met, then it is not required to ground the generator frame:

The generator is mounted to truck or trailer

The auxiliary power is taken from receptacles on the generator using a cord and plug arrangement

The receptacles have a grounding pin

The frame of the generator is bonded, or electrically connected, to the truck or trailer frame

2. If either of these conditions are met, then the generator frame must be grounded:

The generator is connected to a premises wiring system. For example, to supply power to a house during a blackout.

The auxiliary power is hard wired into the generator without the use of cords and plugs.

The summary above does not go into details and the reader is urged to consult their local electrical codes and ANSI/NFPA 70, "National Electrical Code" for the specifics.

Extension Cord Grounds

Extension cords should be periodically tested for ground continuity. Extension cords lead a rough life while lying on the ground; they are under foot and prone to damage. The use of a receptacle circuit tester will confirm that all of the connections are intact within the cord, plug and receptacle.

Welding Circuit Shock Hazards

Utilizing proper grounding in the welding environment is a good practice, but it does not remove all possibility of electrical shock. The welding circuit is energized by welding voltage. A person will receive a shock if they become the electrical path across the welding circuit. Precautions must be taken to insulate the welder from the welding circuit. Use dry insulating gloves and other insulating means. Also maintain insulation on weld cables, electrode holders, guns and torches to provide protection.

Similarly, electric shock originating from the electrical supply system can be prevented. Proper maintenance of electrical equipment and extension cords will insulate the welder from electrical sources.

Information Sources

American Welding Society, ANSI Z49.1:2005 "Safety in Welding, Cutting, and Allied Processes."

National Fire Protection Association, NFPA 70, "National Electrical Code", 2005.

American Welding Society, Safety and Health Fact Sheet No. 29, "Grounding of Portable and Vehicle Mounted Welding Generators", July 2004.

American Welding Society, AWS A3.0-2001, "Standard Welding Terms and Definitions."

instant gratification by hard work and determination granted by GODS hands

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

Re: Grounding a welding table?

Thanks for the info!!! I was just looking at the Miller manual and it has a detailed procedure on grounding. I will post it tomorrow.

- frankysfree

- Posts: 119

- Joined: Thu Jun 14, 2012 9:12 am

Re: Grounding a welding table?

I had a similar problem with my synchrowave 250 and it turned out the clamp on the end of the ground cable was loose. It was the big C-clamp and the way it holds the cable tight is you turn the end part of the clamp. Its unnoticeable if its loose but the cable hasnt come out yet. Hard to explain how it works but if you have the same ground clamp on yours pull the plastic end back and look at it.

- Dale M.

- Posts: 1673

- Joined: Mon Oct 05, 2009 8:09 am

Re: Grounding a welding table?

The ground lead from TIG machine is grounding table.... There is no earth (ground) connection in this ground scheme...bones wrote:Thanks - I have been grounding the table as that has worked well for the MIG. I am using the foot pedal. My problem may be arking too far away since I'm just learning TIG. My confusion is that if the wheels are rubber what's grounding the table? Even if the ground from the welder is attached to the work or the table the table is still mounted on rubber?

The circuit is from TIG machine to torch tip, through arc, to work, back ground clamp, to TIG machine... Anytime you get across the circuit its going to bite you...

Dale

"Fear The Government That Wants To Take Your Guns" - Thomas Jefferson

1970 "Kellison Sand Piper Roadster"

1970 "Kellison Sand Piper Roadster"

-

Steve Arndt

- Posts: 7419

- Joined: Sat Mar 10, 2001 12:01 am

Re: Grounding a welding table?

Sweaty arm wresting on the table with high frequency start will tickle you. No big deal here. make sure the clamp is good and secure on the table (workpiece) or it will bite you on Hifreq.

Steve

My Baja Build

My Baja Build

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

- SCOTTRODS

- Posts: 630

- Joined: Sun Nov 07, 2010 7:15 am

Re: Grounding a welding table?

You can never have too much overkill.bones wrote:I found these pictures in my Miller manual

Looks like even the grounds are grounded overkill?

I have found them completely missing more than once. - PILEDRIVER

Some pics of My Powder Coating work

http://s244.photobucket.com/albums/gg6/terrellster/

My Facebook Page for Powder Coating

http://www.facebook.com/profile.php?id=100001788886297

Some pics of My Powder Coating work

http://s244.photobucket.com/albums/gg6/terrellster/

My Facebook Page for Powder Coating

http://www.facebook.com/profile.php?id=100001788886297

- Dale M.

- Posts: 1673

- Joined: Mon Oct 05, 2009 8:09 am

Re: Grounding a welding table?

Most of what you find in manual about grounding will because of liability and yes most of it is practical, but as of yet most shops I have ever been in has not really gone to effort to ground EVERYTHING.... And most home/farm shops usually don't bother with any of it....

Just be aware of general area you are using, meaning welder, table, you.... You might try the ground bond between breaker panel welder chassis and table to common ground rod but I think it will not improve situation very much.... What has already been discussed on how you are putting your body parts into circuit is what has to change...

Dale

Just be aware of general area you are using, meaning welder, table, you.... You might try the ground bond between breaker panel welder chassis and table to common ground rod but I think it will not improve situation very much.... What has already been discussed on how you are putting your body parts into circuit is what has to change...

Dale

"Fear The Government That Wants To Take Your Guns" - Thomas Jefferson

1970 "Kellison Sand Piper Roadster"

1970 "Kellison Sand Piper Roadster"

-

bones

- Posts: 407

- Joined: Sat May 04, 2002 1:01 am

Re: Grounding a welding table?

I think you're right about body parts. I saw this "tip" on a Miller welding forum but not sure of it "tywrap your tig torch leads and work together for the first 2' after leaving the machine will minimize the intereferance." Not sure about this any thoughts?

- fusername

- Posts: 6806

- Joined: Sun Jan 28, 2007 11:26 am

Re: Grounding a welding table?

even the raw materials on the wall are grounded! that said, if you are getting mild shocks, anything above a tickle, I would check your grouding in the building. namely the outlet you are using, the ground for the breaker, etc. if you are not having any welding issues it is probably not the welding cables themselves, but further up stream. they make cheap plug in testers for this, but I don't know if they make 220 socket versions, nor do I know if they will show a bad ground, they probably will show a disconnected ground, but not a poorly connected one.

tiewraping the wires together helps since one cable is out the other is in. They both spit electrical noise, but since it goes in opposite directions it will cancel a bit if the noise starts in the same spot in space, hence wrapping them up together. unrelated to the issue at hand tho. this is a floating ground problem methinks.

tiewraping the wires together helps since one cable is out the other is in. They both spit electrical noise, but since it goes in opposite directions it will cancel a bit if the noise starts in the same spot in space, hence wrapping them up together. unrelated to the issue at hand tho. this is a floating ground problem methinks.

give a man a watch and he'll allways know what time it is. give him two and he can never be sure again.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.