I totally agree, electromechanical would be by far better, but that surely takes it out of my realm of affordability. Furthermore this goes into my pile of things to do when I hit the lottery so high that I can never work again and never run out of money, but I digress.Ol'fogasaurus wrote:Hmmmm, I see said the blind carpenter as he grabbed his hammer and saw!I think you are missing a bunch of things going on and are going to have to get rid of the mechanical concept and go electrical (micro sensors for example); too much monkey motion in the mechanical idea based on what I am now seeing. I don't think you want to put additional loads into the steering like that either. Also, I think you are not going to want that to be full time for several reasons like fuel economy for instance so you could easily shut it off if it were electrically based. think about how some of the cars can change their suspension on the fly from Grandpa/Grandma to Good-lord-Lucy, hang on to your depends!

As for the suspension moving etc, I think this could be accounted for, but I had thought of that. I actually kinda took this idea from the early VWs that had cable operated brakes as did Model T's have mechanical brakes. Come to think of it the parking brakes are cable actuated and the suspension moves up and down.

The load on the steering could be a concern, and some calculations would need to be done to balance everything out but with some of the abuse that I know I've put my VW's through over the years, I would think some basic gusseting on the spindle steering arm would be sufficient. There is only one way to know for sure.

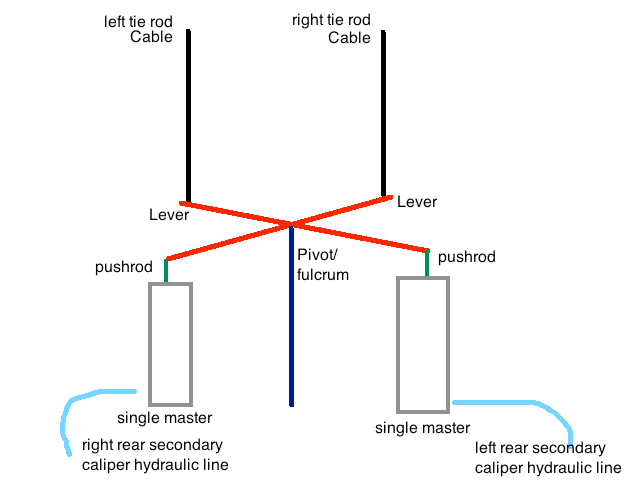

Here is why I would do it the way I proposespectre6000 wrote:Do you see any advantages to a cable system over the lever system I described (and squiggled at) earlier?

Simplicity - to me it's more simple this way. I also realize I may not think like most people and to some this may seem more complex.

Adjustability - I feel the adjustment could be done in more fine increments

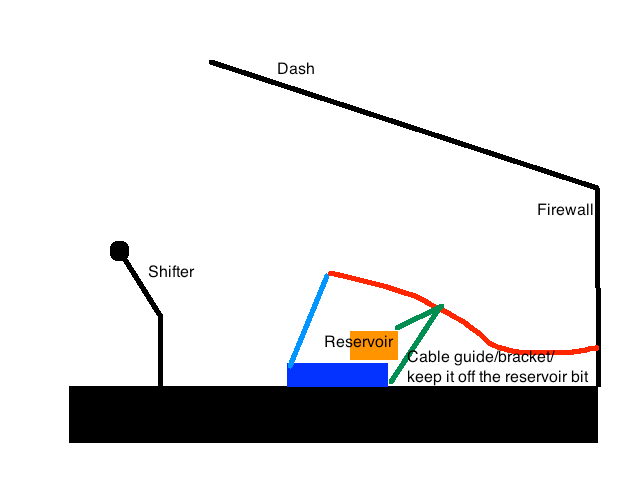

Hole in the front firewall - they are small and easy to make. If I am imagining yours right there would need to be a hole big enough for the lever to pass in and out of

Space limitations - The under fuel tank is a crowded area, I discovered this when exploring the idea of a pinto manual rack, which is now on the back burner for now.

From a functional stand point, your idea would work great. One thing I would explore to possibly improve your specific idea, I would consider connecting the end of the brake lever to the tie rod via a pair of heim joints. The inherent slop that exists may be enough such that when you slid the base back to disengage the system it wouldn't apply enough braking force to do much, but when you slide it forward then the heim joints are perpendicular to the lever and will actuate it. It could also be there is not enough slop and it wouldn't reduce the braking forces enough to make them not existent.