Wow, thanks for the reply, Paul.

Very much appreciate your sage advice.

After reading my eyes off,

it is starting to make sense what needs to be done here.

Will need that dual bearing retainer, some nuts, and whatever gets found to be bad..

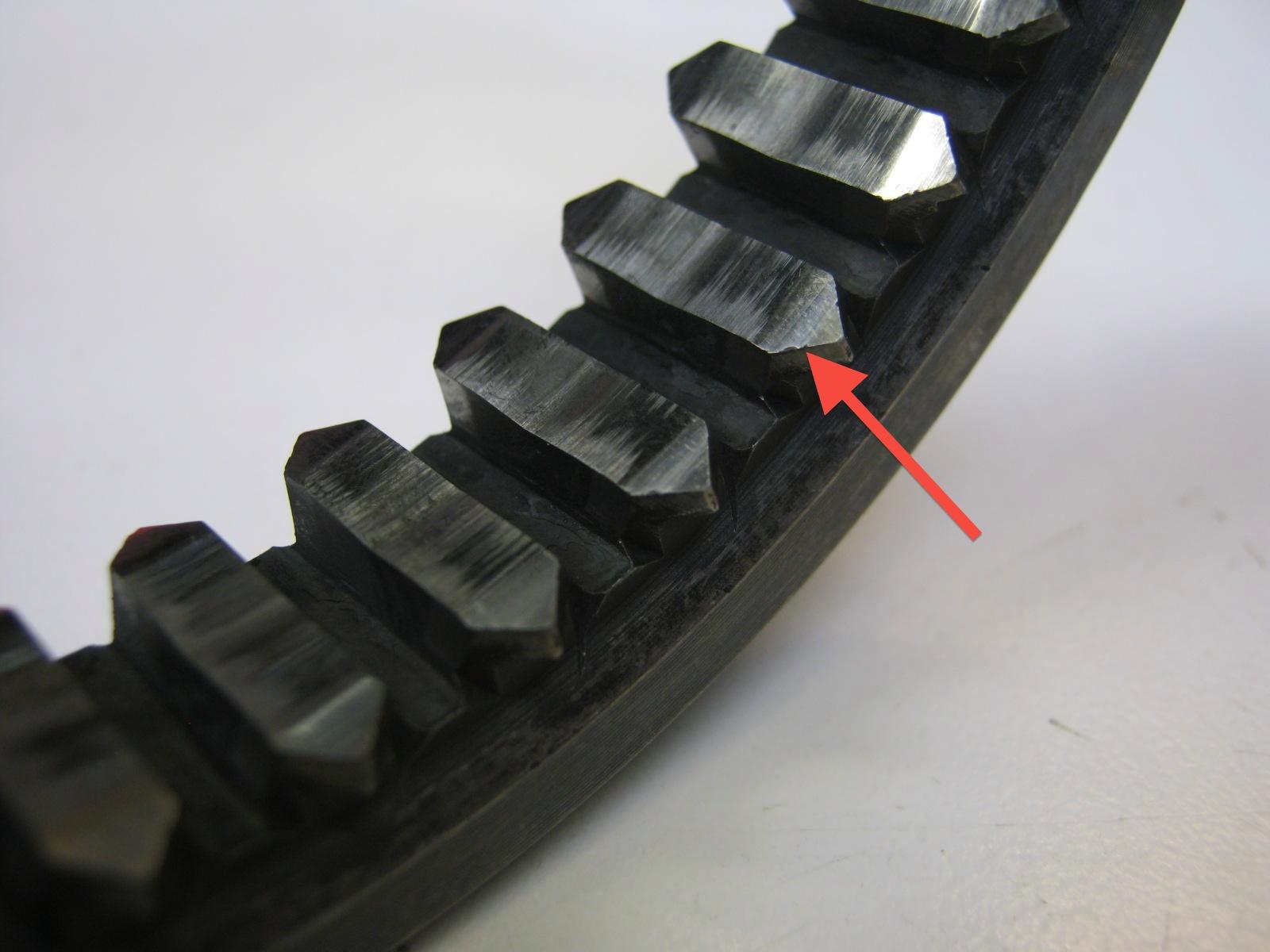

1St, re-measuring the shim, it indeed is .004", so .1mm.

2nd, how to approach this.. (Hope you have a minute to read a long post here - apologies in advance).

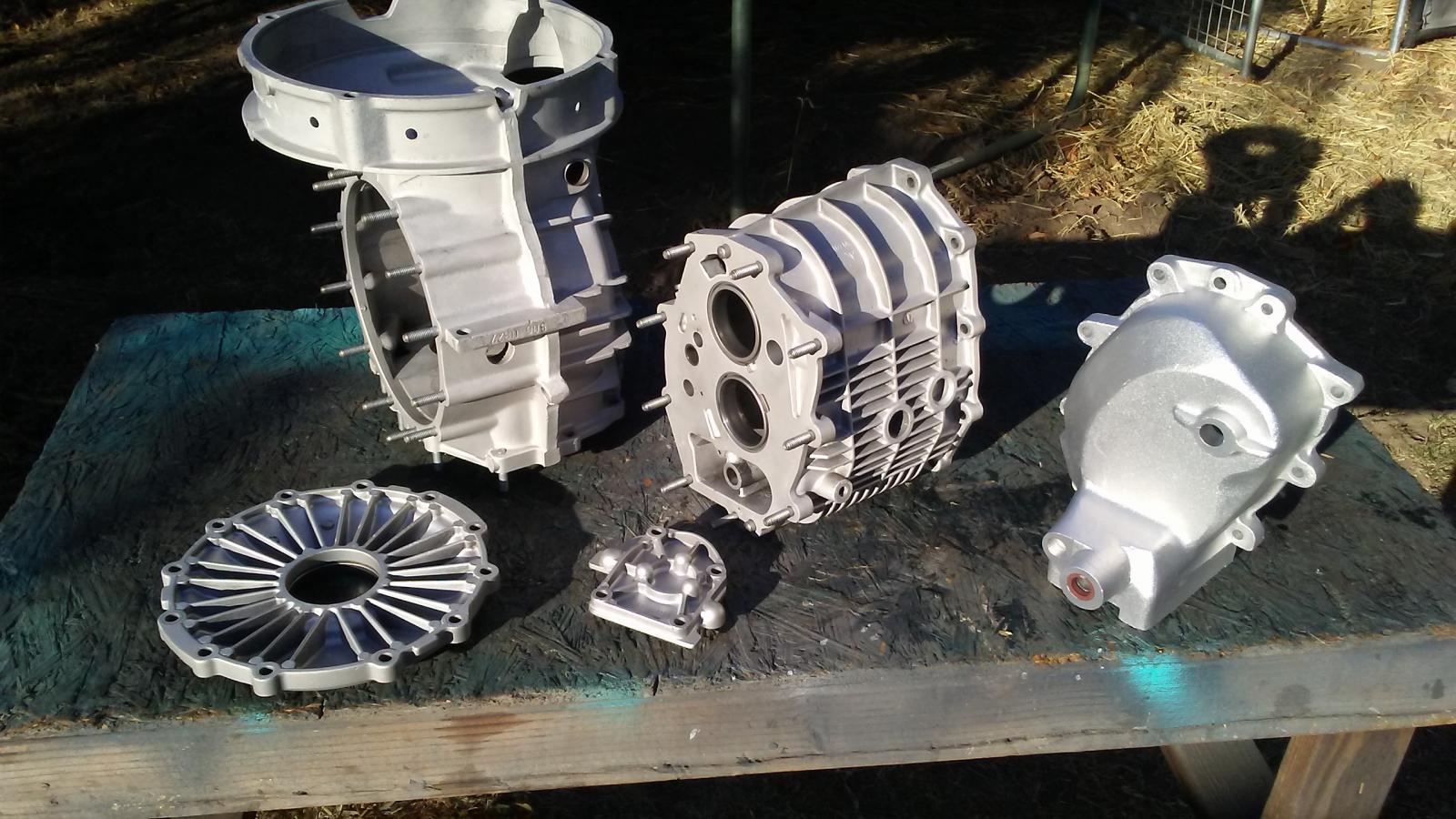

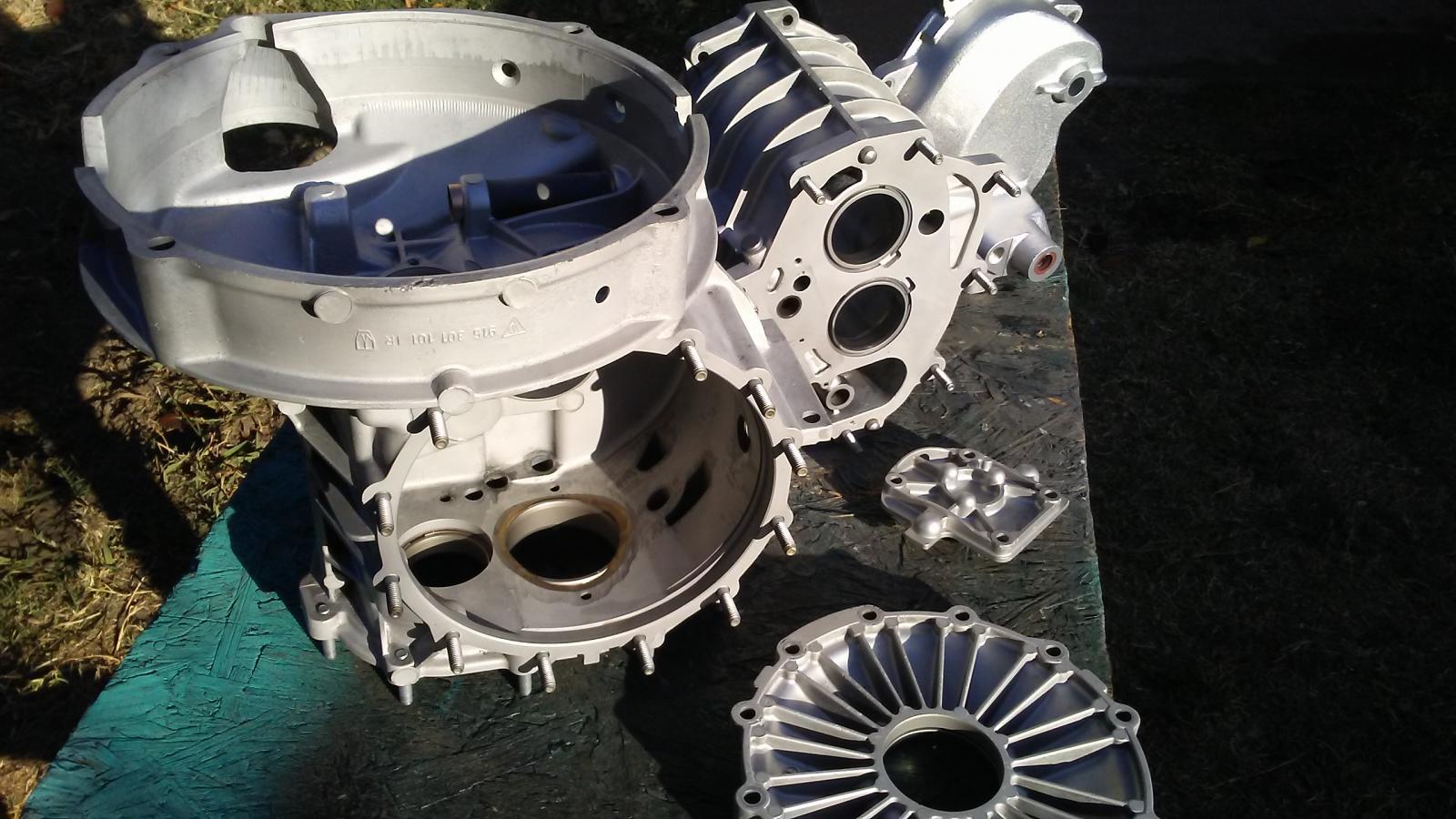

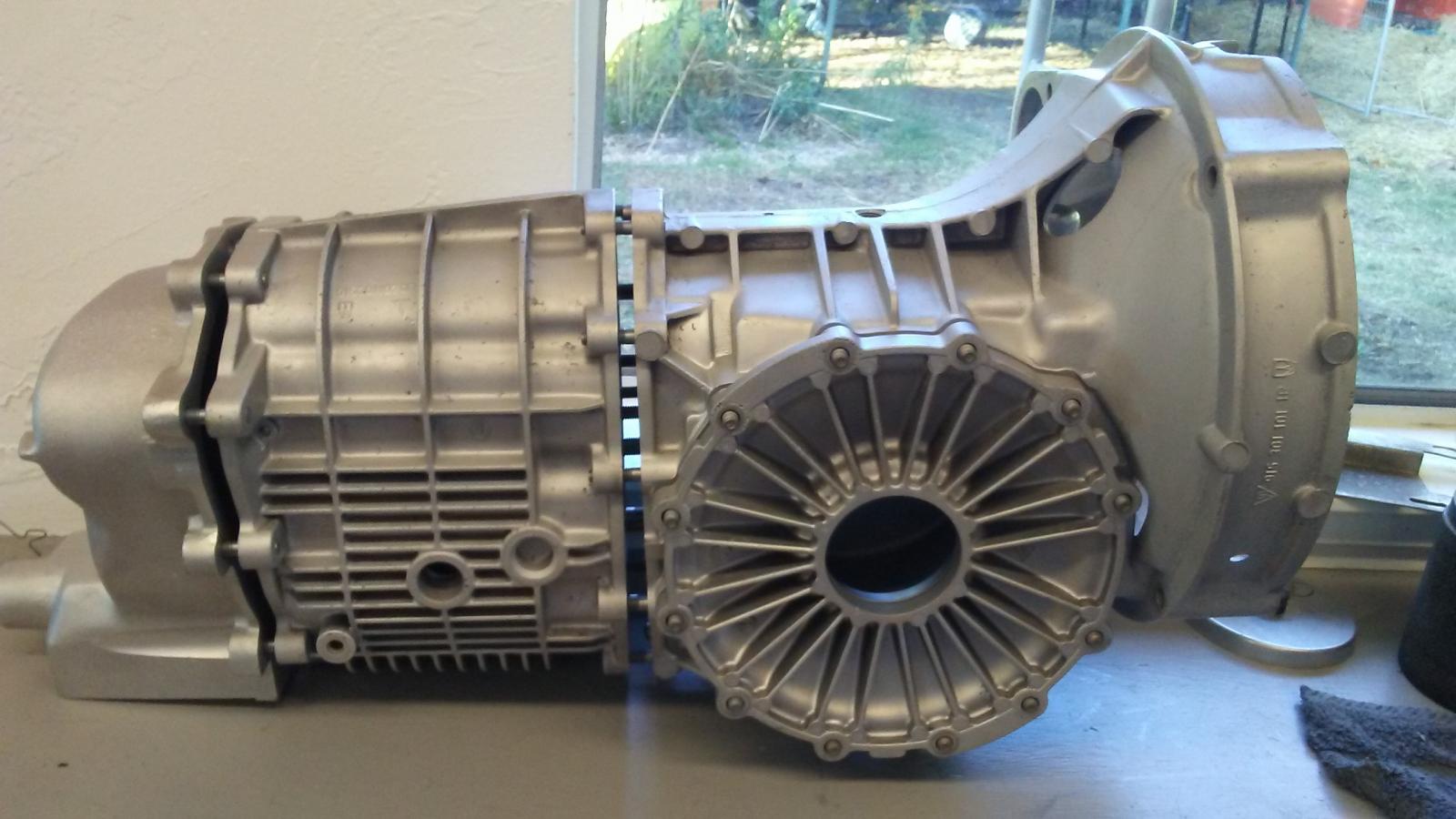

This particular trans is actually a 923 out of a '76 912E.

It was purchased after the car had an engine fire, and was totaled.

Then, the wrecking yard dropped it from way up high, breaking the nosecone.

It was sold to me as a very low-mileage original trans.

They claimed it had only like 80K on the clock, or so.

Supposedly it was driven by a dentist's wife.

(Junkyard tow truck driver story, no doubt).

Anyhow,

Because mag is flammable, and it was getting a bug@5-speed nose cone anyways,

I paid a local Porsche/Audi/VW high-end shop to 'go through it'.

Wanted to know if it was damaged in the fire, had been re-built before, if they thought the story was true.

It came back later, with them saying it was indeed a perfect low-mileage 923, and they were the first to open it.

After having it for a while, never even putting oil in it.

I got up the courage to open it up myself.

Obviously, looking at that shim, it was a good idea.

The other thing about it, was that it was dirty.

Inside especially..

There is a grit all over from dirty hands and/or lying on a dirty bench.

So,

On to my question..

Before, with rebuilt beetle tranaxles.

There's this "they're never quite the same after a rebuild" thing.

None of the rebuilds I ever had shifted as effortlessly, or were as quiet as an assembled-by-VW original.

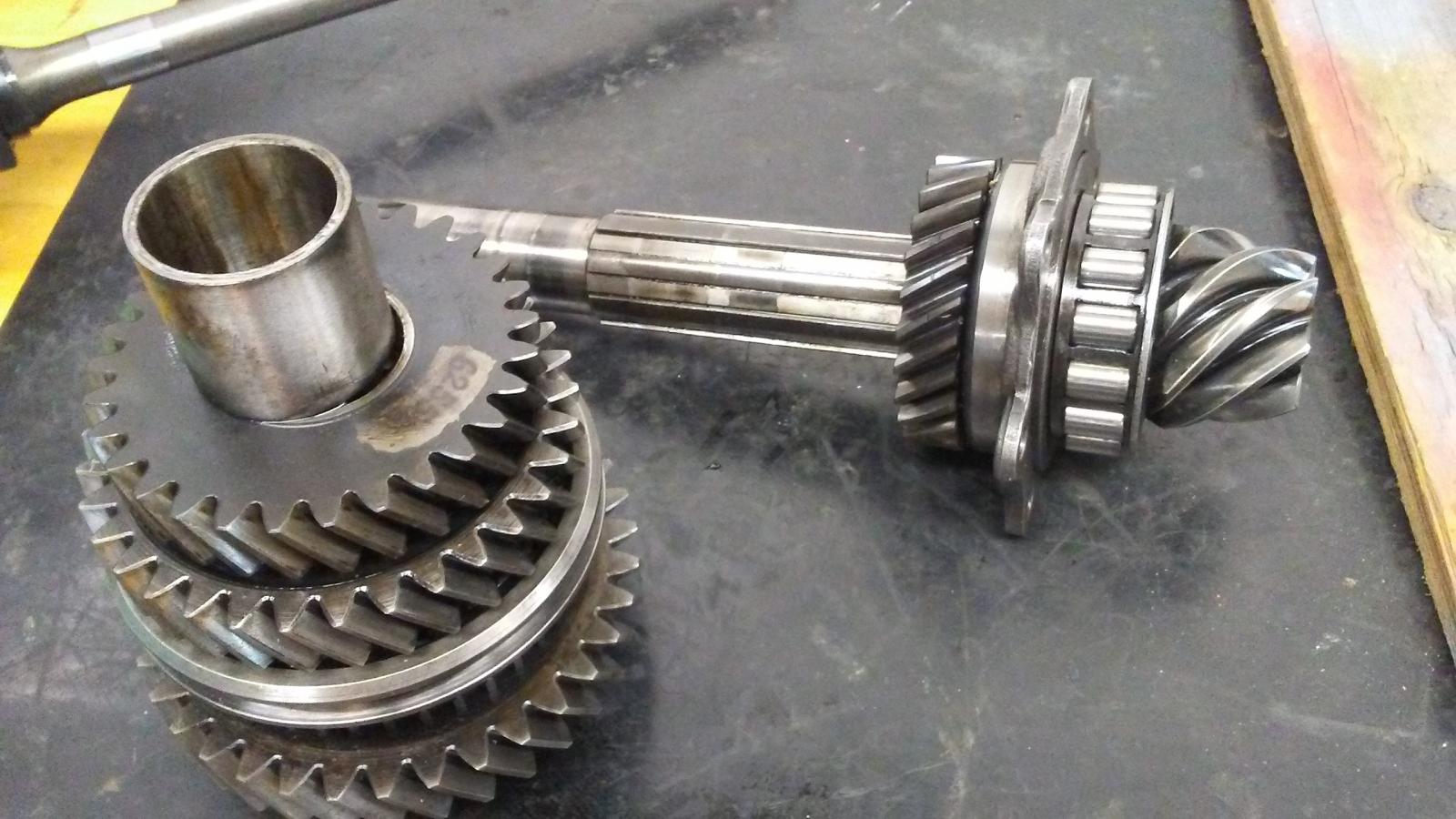

What I would like to try here with my 923 is to clean and save everything OG if at all possible.

If the story about low miles and never apart is true, then this *could* just go back together, and be nice as OG.

Right?

That's why changing out that shim had me all squeamish..

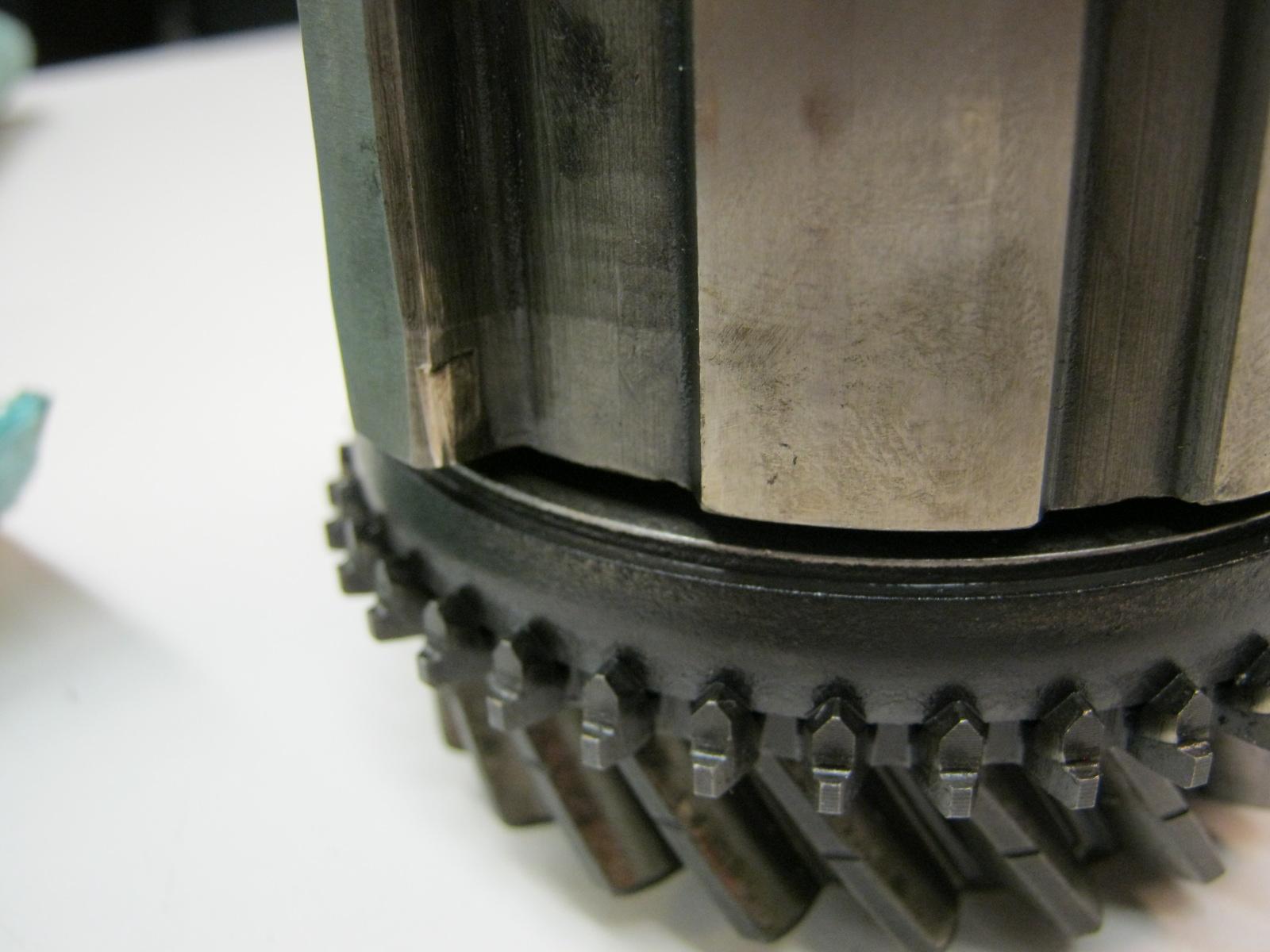

I plan on popping apart all of the stacks, and opening the synchro assemblies,

And see if it is all indeed as nice as it is supposed to be,

With an eye on cleaning it up, and putting it back together like it was.

Would moving to the dual bearing cover require me to re-set the R&P?

Are the new bearings likely to be as nice in quality as the OG ones?

Remembering that the 912E had a feeble smogged-out 4-banger, unlike any of the sixes the car was designed for,

Maybe bearing replacement isn't SOP here.

(Or even the dual bearing cover?)

My motor will be a type 4, and unlikely to ever be over 200HP.

Could I just take the entire gear stacks, and put them in the parts washer?

(Citrus/water washer like a dishwasher)

I would be blowing them off with compressed air right away,

Lying them in the sun to dry,

And maybe hosing them down with some WD-40.

This would make the dis-assembly/inspection process far more fun..

(Sorry if this is a dumb question, I heard that synchro coatings could react to solvents).

I also want to get the burned-on oil/grit removed from the outside of the case by vapor (wet) blast.

Should I just mask off the 5/R detent assembly,

Or do I dare drive out these roll pins and take this apart?

Again,

Thanks for tolerating a barrage of newbie questions.

I'm super excited about this,

And,

Been having really good luck so far!