Dave posted this in another topic:

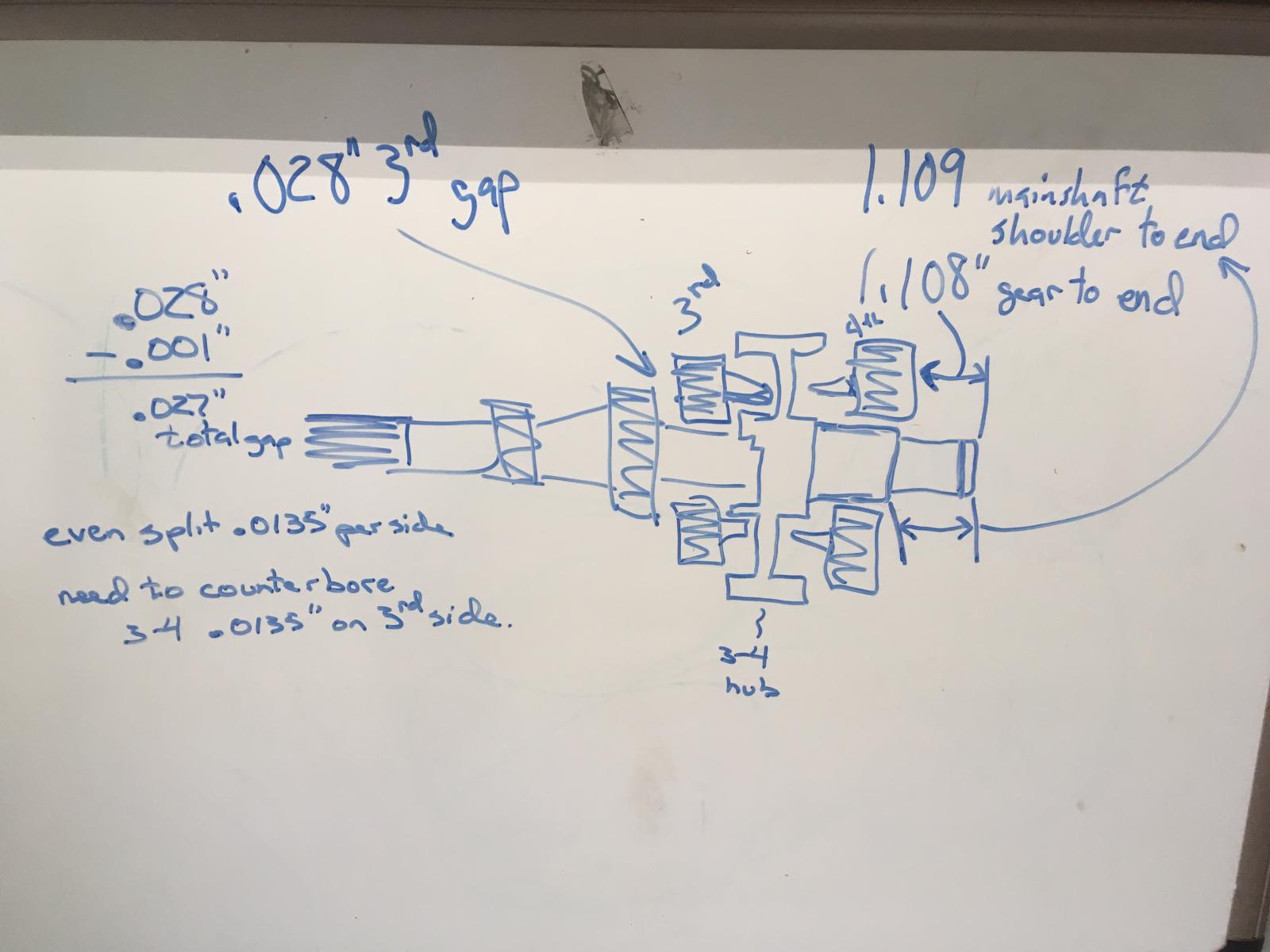

I bet Dave's lathe is a few steps from his work bench so it's easy for him to cut-n-check. My lathe is about 10km away, so does anyone use a predetermined amount of machining on the hub?dangerous wrote: ↑Tue Apr 15, 2014 12:57 pm The 091 circlip is 1mm thicker, (approx. 2.5mm total thickness) so I always begin with a cut of 0.87 to 0.9mm on the 3rd gear side to get it close. Once the end float is set for 3rd, then do similar on the 4th gear side, bit by bit, so the clip is tight, width wise.

You must still check that you have enough end clearance on 4th with the hub pressed lightly against the 4th-side-circlip. By all means, centre the hub after this check, but on operation, it will always end up closing the gap on 4th, so make sure you have the end play in that thrusted position too.(no less than .004", for me never less than .006"!!)

3rd gear can have a little MORE play, since its helix will help pull it into gear, but 4th gear pulls away from the hub, so too much end play means the dog teeth have to work harder to keep engaged when the end play is large.