Welding Projects & Pictures

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

Welding Projects & Pictures

Does anyone have any welding and fabrication projects that they would like to share?

Hot, humid air is less dense than cooler, drier air. This can allow a golf ball to fly through the air with greater ease, as there won't be as much resistance on the ball.

- Leatherneck

- Moderator

- Posts: 17104

- Joined: Sat Jul 01, 2006 6:47 pm

- david58

- Moderator

- Posts: 14096

- Joined: Sun Oct 23, 2005 6:14 pm

-

Chris V

- Posts: 3402

- Joined: Tue Sep 03, 2002 12:01 am

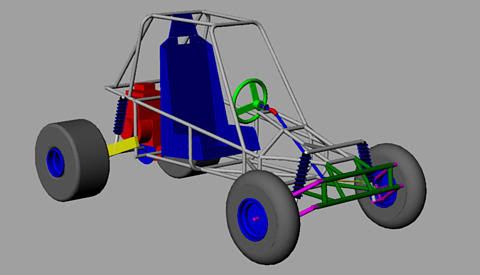

Well thanks...That took me awhile...and honestly it was the only design stuff I've ever done using any software programs. It was a trial version of I think "Rhino CAD" that my junior high school Tech teacher told me about. Seriously cool stuff, I just barely touched the surface of what is capable but it was enough to really help.Leatherneck wrote:Chris V, man props to you buddy you have some talent. How long have you been at it? Is this a program you have or somebody elses? Would like to hear more about it.

Keep up the great work , thanks for the pictures.

http://www.joesracing.com/

Son of Marc

Son of Marc

-

Chris V

- Posts: 3402

- Joined: Tue Sep 03, 2002 12:01 am

We keep busyDavid58bug wrote:Chris V it looks like you have a few projects going on there. Nice pics.

[/img]

[/img]http://www.joesracing.com/

Son of Marc

Son of Marc

- slowtwitch

- Posts: 533

- Joined: Mon Nov 08, 2004 9:38 am

My engine test stand. This is one of the first things I ever welded. I made it in November of last year.

The place where I work, was scrapping a bunch of these carts. I just added some metal. I'm going to add a control board, with gages and switch.

and here is my current project... with only a few months of welding experience under my belt.

putting in a new tray and a removable apron.

some quarter panel work, not finished ...yet

Repaired some rusty spots near the rear vents...

Not pictured is the new front clip, heater channel, and left side "A" post.

The more i weld, the more comfortable i feel about doing it. Now, i just got to remember to shut of that friggin gas valve on the bottle., when I'm done welding.

pete

The place where I work, was scrapping a bunch of these carts. I just added some metal. I'm going to add a control board, with gages and switch.

and here is my current project... with only a few months of welding experience under my belt.

putting in a new tray and a removable apron.

some quarter panel work, not finished ...yet

Repaired some rusty spots near the rear vents...

Not pictured is the new front clip, heater channel, and left side "A" post.

The more i weld, the more comfortable i feel about doing it. Now, i just got to remember to shut of that friggin gas valve on the bottle., when I'm done welding.

pete

-

allsierra123

- Posts: 849

- Joined: Sat Aug 19, 2006 10:32 pm

- rexr

- Posts: 158

- Joined: Wed Nov 30, 2005 11:09 am

No it's just a standard 36" fiberglass bench with a custom cover that I bought from a guy.. That's why I had to make the frame for it..allsierra123 wrote:Rex is that A childs seat? Curious about what Size it is.I would like to do something like that In the rear of mine.But I want to build the cage so that it is easy to get in and out of.

I just cut out the horizontal bar on the cage that ran behind the seats because it was in the way both getting in and out and sitting back there even for my 6 year old and his friends.. It is nearly impossible for adults to get back there.. I am going to move the horizontal cross member down to foot level so that I still have some stiffness in the cage..

I am looking at moving the rear portion of the cage back so that it is closer to the firewall but I am not sure how to tackle it yet..

The big thing for access is being able to move the seats forward enough to allow someone to crawl back there. The set up I have is ok but I saw a guy in the desert that had taken seats out of some Japanese car that had a much better hinge system that mine which just pivots at the lower front of the seat. His worked on more of a parallelogram system where the whole seat moved forward versus just tilting..

-

allsierra123

- Posts: 849

- Joined: Sat Aug 19, 2006 10:32 pm

-

allsierra123

- Posts: 849

- Joined: Sat Aug 19, 2006 10:32 pm

- rexr

- Posts: 158

- Joined: Wed Nov 30, 2005 11:09 am

Got an opportunity to do a little fab work this weekend.. I cut the front of the body off to put a one piece front end on and as soon as I made the first cut I realized that I had just cut off my tank mount as I am running the stock tank..

So here is what I came up with..

Overall I am pretty happy with it.. I was able to tie into the body mounts that are on top of the beam so I can utilize the rubber bushings that are there to help with some of the shock and vibration..

So here is what I came up with..

Overall I am pretty happy with it.. I was able to tie into the body mounts that are on top of the beam so I can utilize the rubber bushings that are there to help with some of the shock and vibration..