Page 3 of 3

Posted: Fri Nov 03, 2006 4:47 am

by Andy K

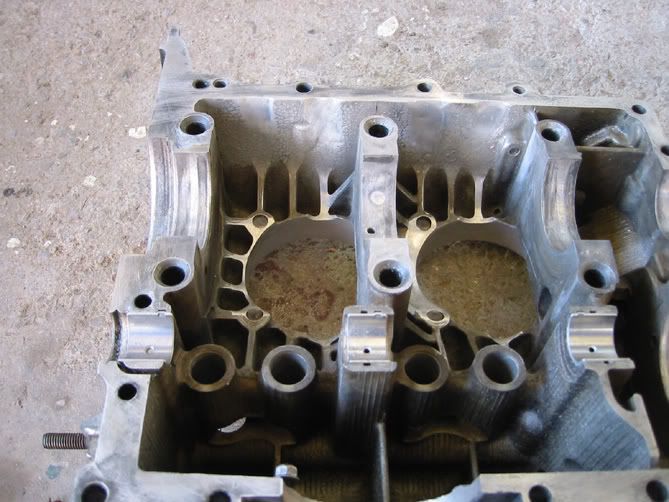

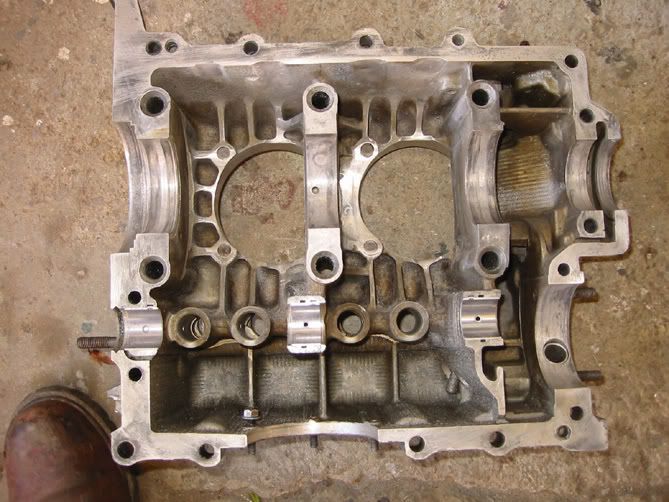

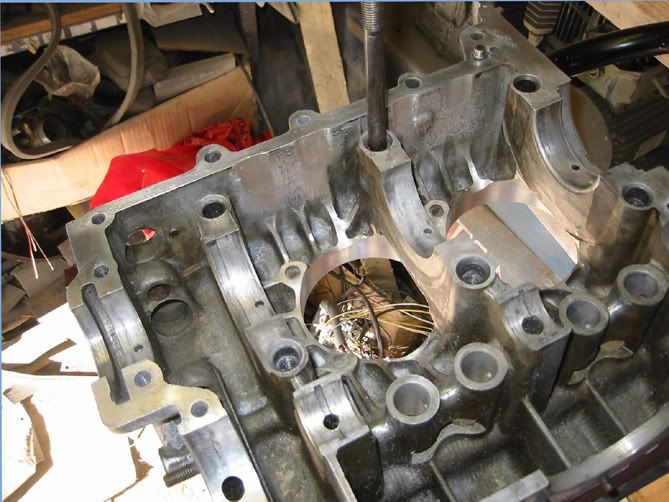

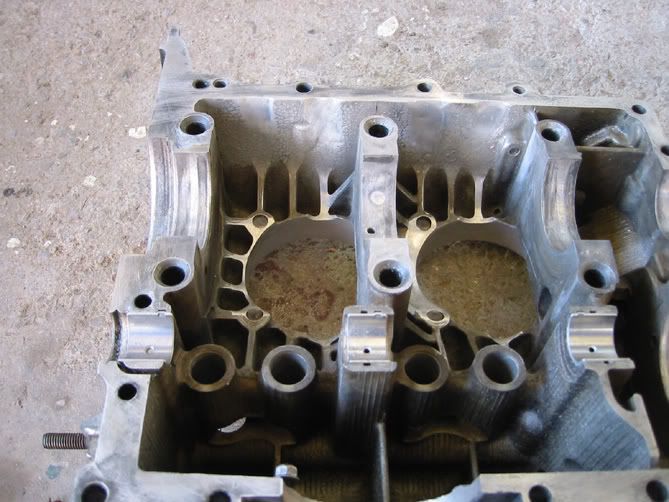

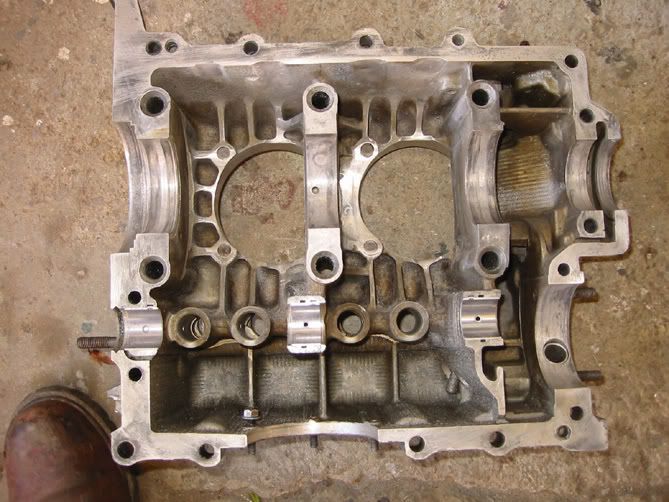

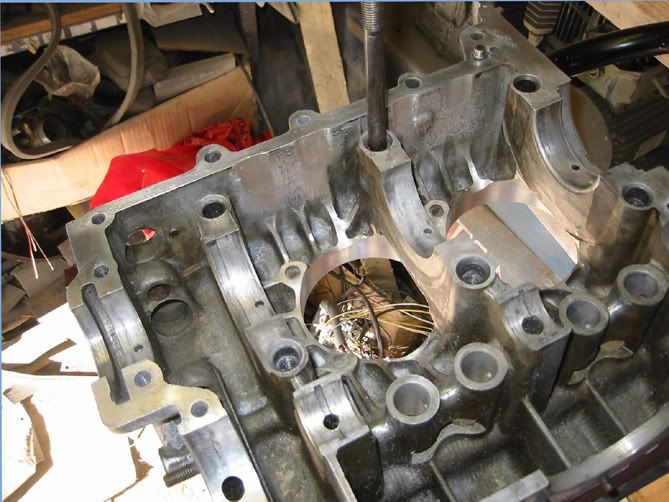

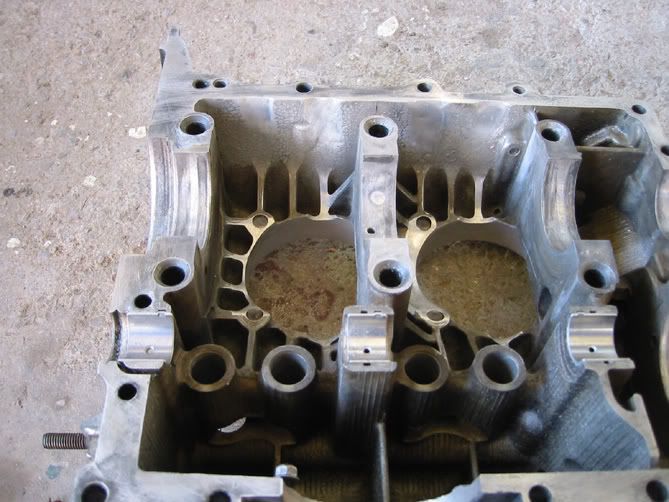

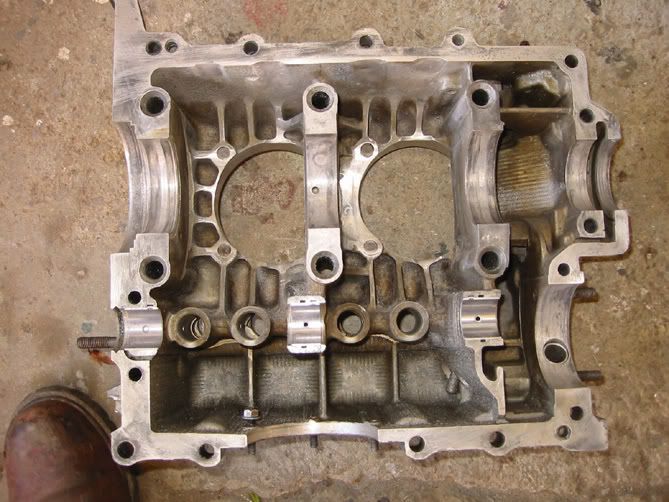

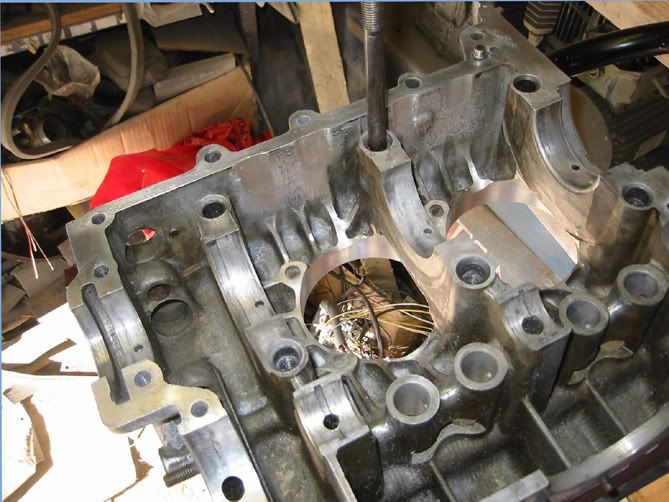

For Greg. Here are the pics of the clearance work I have done so far, the crank and rods rotate, just got to set up the timing gears and work out which bits of the cam need a little work. It hits just behind the centre bearing.

As said before I am fitting a CB 82mm crank with CB H beam rods.

I actually found that carefully using a belt sander was the quickest way of removing material, maybe my die grinder is dying.

Posted: Fri Nov 03, 2006 6:13 am

by madmike

Hey Andy, Looks good

Keep us posted,Brrrrr it's snowing over here

Posted: Wed Nov 15, 2006 5:59 pm

by terry cloyd

Please don't stop there, don't forget the piston or maybe the valve cover.

Posted: Sun Dec 03, 2006 2:31 pm

by Niels-Erik

Sorry! Iam lazy, and i now orderd a CB aluminium cace for my 2332.

Its all reddy clearet for the stroker.

Cant wait to get startet.

Niels Erik

Posted: Sun Dec 03, 2006 2:35 pm

by gblakeney

My case is together, head port work complete, and cleaning the cylinders / pistons now and checking ring gaps.

Hopefully top end will go together tonight.

Posted: Wed Dec 06, 2006 6:41 am

by madmike

hey Greg,Here's a tip for you,after you set the end gap,spray WD-40 in the cyl's and the pistons The rings will seat quicker,I've seen guys coat the stuff with STP and motor oil and wonder why the rings don't seat

later Mike

Posted: Fri Aug 14, 2009 6:53 am

by madmike

Well It's 3yrs old and still runs strong

Specs are 84x94 Porsche 912 rods,10lbs flywheel, all balanced ,W120 cam,welded P&P heads 42x37.5 33cc,I did move the CR down to 10.5:1,match ported intakes and 44 Webers w/ updates 38vents,4qt deepsump,full flow,36hp doghouse, all MSD, 6al 2step,this year,but ran good with a 094 w/points, 1 5/8 merged headers,I had this in a SandShark Tub Buggy for the firsts season,Spanked a lot of Mustang GT's/Cobra's, Vettes

But they bitched about me being so 'Lite" so I found a 72 Drag Bug 1720lbs with me in it,Full cage,glass frontend and rear fenders,Best times are 8:4 @80mph in the 1/8 mile,all I've done to this motor 3yrs was retorque the heads once and change the oil

and I'm still spank'in 396 Chvelle's,New vettes and Stangs/Cobras but this time with a "Bug"

Madmike

Re: Stroker case clearancing

Posted: Tue Dec 22, 2009 11:14 am

by madmike

I'm finally stepping up to some 48 IDA's

for the 2010 season.I am also switching to 1:25 rockers with triple valve springs, I removed the flat wound ones when I first built this because I did do some street driving but now it's just a drag bug

Re: rods?

Posted: Mon Jun 14, 2010 7:51 pm

by 3literboy

nsracing wrote:Buggsy wrote:Don't buy bits and a die grinder unless you have access to a professional size air compressor. The thirty gallon, one lungers that most of us use to run impact wrenches will burn up before you get the job done. Die grinders consume a huge amount of air.

You are NOt going to run the grinder all day long. You just need short bursts of spins. 30 second spins and check the cut....spins some more and check the cut.

I do not know anyone that runs the rotary file continously.

Here are more pics..

cam clearance..

I clearance the rods too! That corner of the rod where the rod bolt end can be seen can be rounded a bit as part of the rod balancing etc. It also eliminates the requirement to take large amounts from the cam. The cam notches seem just a bit to deep for my taste. I take it down about half that much and finish the cam with a hand file. Then I polish the areas with a 3m pad on a diegrinder.