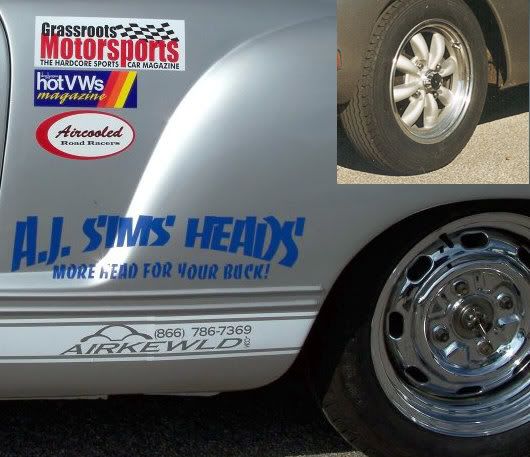

RetroRacing's 53 has used both steel and alloy wheels. Here, at Road Atlanta, we ran the eight-spoke EMPI style aluminum alloy wheel. The ones shown are actually sold by American Eagle. 15x5.5" with 4" backspace.

RetroRacing's 53 has used both steel and alloy wheels. Here, at Road Atlanta, we ran the eight-spoke EMPI style aluminum alloy wheel. The ones shown are actually sold by American Eagle. 15x5.5" with 4" backspace.

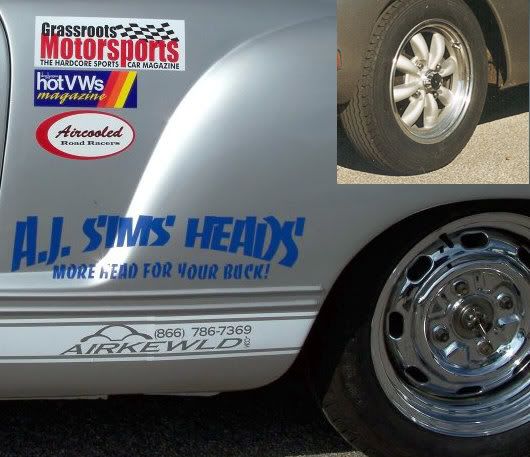

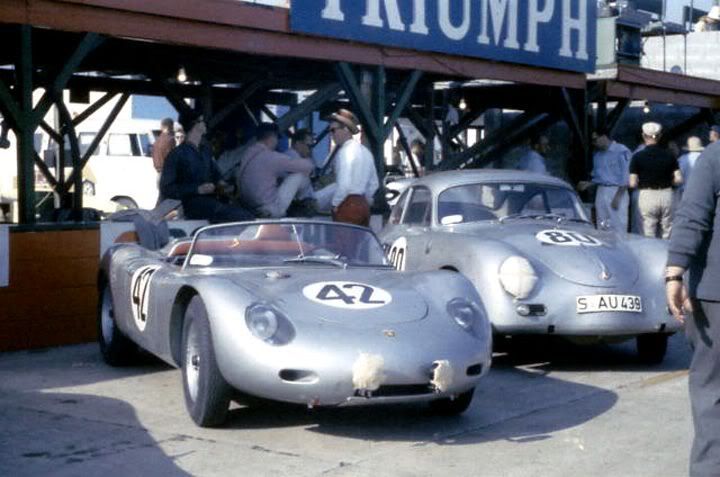

Above: Our 261 Carrera Panamericana car ran traditional steel "disk" wheels. EMPI 8-spoke style wheel inset for comparison. The steel wheels here are original Mangle, 15x5.5" with 4.75" backspace.

Wheels are perhaps the most popular "looks" item on cars, but here we're talking about functionality for high performance duty.

Above: Our 261 Carrera Panamericana car ran traditional steel "disk" wheels. EMPI 8-spoke style wheel inset for comparison. The steel wheels here are original Mangle, 15x5.5" with 4.75" backspace.

Wheels are perhaps the most popular "looks" item on cars, but here we're talking about functionality for high performance duty.

Original VW's and Porsches came with steel wheels, and had them when wire wheels were still considered mandatory sporty car equipment. The steel "disk wheel" was a leap ahead of the wire wheel technologically. They didn't flex like wire wheels, tended to stay round and true, and cost less.

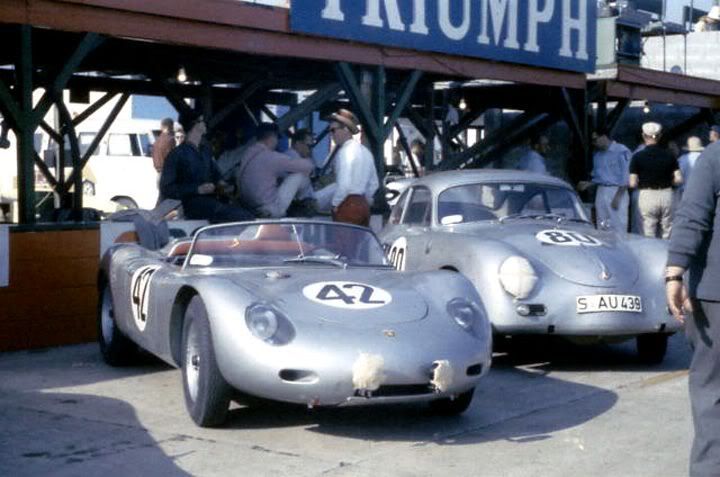

Above: 1957. A D-Jaguar runs steel disk wheels, giving up on the traditional (and sexier) British wire wheels for better handling.

Above: 1957. A D-Jaguar runs steel disk wheels, giving up on the traditional (and sexier) British wire wheels for better handling.

The C-Jags ran on wire spoke wheels.

The C-Jags ran on wire spoke wheels.

World War II brought about the widespread use of structural, lightweight magnesium parts, especially in aircraft. And the automotive and racing world took advantage of the new technology where it could. Obviously, the VW, with its magnesium alloy engine and transmission cases were ahead of the tech curve.

The disk brake and magnesium wheels were aircraft developments that fit right into automotive competition use. The problem with magnesium aircraft wheels was fire. A real mag wheel burns in an absolutely spectacular way at 2,500 °F. Tire blowouts on landing sometimes made that happen. Early experiments in machined mag castings for Formula cars got mag wheels banned in the UK for some racing classes.

Aluminum-magnesium alloy wheels were stronger than magnesium itself and provided far less drama if scraped along the road. American Racing Equipment introduced alloy "mag" racing wheels for dragsters in 1960, and like they say, the rest is history.

We still call magnesium-aluminum, and even just aluminum wheels "mags" today. Old habits die hard. In this article, we'll call them alloy wheels.

It is a misconception that alloy wheels are always lighter than steel wheels of the same size. Sometimes they're lighter, sometimes the same weight, sometimes even heavier. But weight is not all it's about.

An alloy wheel is made from a machined casting, and is usually true round. The alloy, bolted directly to the brake, is a far better conductor of heat than steel (a big racing advantage), and the alloy wheel is safer overall because it does not flex like steel.

The small-bolt diameter typical in steel wheels sometimes causes the wheel rim to break away from its own center. The wheel center will still be bolted to the brake disk or drum while the rim and tire is bouncing down the track!

It was the wide-five bolt pattern VW and Porsche used on its steel wheels that allowed the Porsche 356 and 550 Spyders to keep using them in racing when the competition had already begun to switch to alloys.

In defense of steel wheels, center failure is not common, and the 4.75" backspace of the 15x5.5" Mangle wheels allows wider tires than stock.

If you're running steel wheels, remember to retorque the bolts or lug nuts between practice sessions or races. They will loosen up.

On the subject of bolts or lug nuts & studs, VW and Porsche went for bolts because the wheel slightly "centers" better on a brake with bolts (and therefore rolls truer) than with studs. But studs win out for ease of use, explaining why Porsche eventually went to studs.

UNSPRUNG WEIGHT (again)

Lighter wheels reduce unsprung weight, allowing the suspension to follow the road surface (less bounce) more closely with better grip.

STEEL vs ALLOY REPAIRS

If damaged from a pothole or curb impact, alloy wheels are harder to repair than steel wheels, and certainly cost more to replace. Alloy material can bend, but typically chips or cracks.

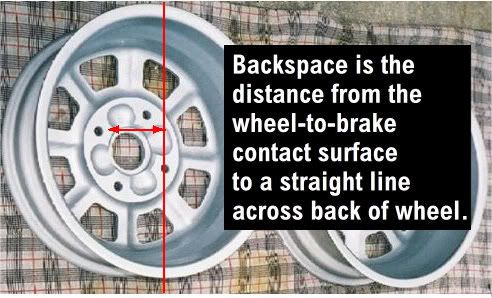

THE IMPORTANCE OF BACKSPACE

Above: The 914 2.0 liter Fuchs wheel in 15x5.5" gives 4.4" of backspace and allows larger tires to be mounted to the Karmann Ghia. MidAmerica Motorworks sells a replica of this wheel (part No. 370-609) but advises that it is not for disk brakes (!) as the wheel strikes or rubs the caliper.

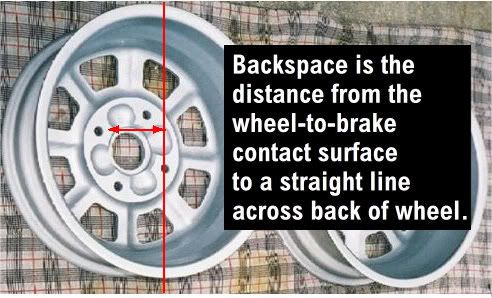

Above: Backspace measurement on a 914 2.0 style wheel.

Above: Backspace measurement on a 914 2.0 style wheel.

Backspace tells you how "deep" the wheel sits in the wheel well when bolted to the brake. Generally speaking, the more the backspace, the wider the tire you can fit in a tight area like a Ghia's rear wheel well.

SPACERS & LUG NUTS/BOLTS

Above: 4x130mm bolt pattern (VW and 914 four-lug) spacer in 1/4" thickness shown.

Above: 4x130mm bolt pattern (VW and 914 four-lug) spacer in 1/4" thickness shown.

Performance Products

http://www.automotion.com sells a good selection of wheel spacers for VW's and Porsches, to include wide-five spacers. The purpose of a spacer is to set the wheel away from the brake (side effect of decreasing backspace) and moving the outer edge of the tire closer to the fender lip.

Spacers can be used to slightly increase track, to move the wheel outward to cosmetically better fill the wheel well, or to space the wheel away from the brake to help clear a caliper.

Be sure the seating area on your lug nuts or bolts has the right taper to fit your wheel! Note that there are shallow and deep tapers. Most alloy wheels use the deep taper.

WHEEL ADAPTERS

Above: Adapters won't get past most race track tech inspections. Wheel adapters are for the street, not racing.

Above: Adapters won't get past most race track tech inspections. Wheel adapters are for the street, not racing.

Wheel adapters have long been part of the VW modifiers bag of tricks, and overall, are handy items. But for racing, don't use them. The faster you go and the more loads you place on your wheels, the less trickery you want. Some Porsche purists even hesitate to use wheel spacers because of the longer bolts necessary ... and we know the story of the buggy guy that ran VW-to-Chevy adapters and won the Sandtrap 150 or whatever ... that was his neck. Be more careful with yours.

WHEELS, SPEED & SAFETY

Above: The RetroRacing crew inspects between sessions.

Above: The RetroRacing crew inspects between sessions.

When you fit a set of wheels and tires, you have to constantly watch them for proper lug nut torque, rubbing both in steering and full up-and-down suspension movement. And out-of-round conditions. And wheel cracks! Make safety inspections routine.

It goes without saying that wheels and tires should be accurately balanced. You can balance a racing tire with a simple bubble balance device, because racing tires require more frequent balancing as they wear. Spin-balance machines are nice for street cars and give you a better balance because the mass of the brake is taken into consideration, but walk over to the Goodyear trailer at the track and see what they're using to balance their tires. Bubble balancers.

...AND IN CONCLUSION

Wire wheels are for looks.

Steel wheels are better than wire and good for racing.

Alloy wheels are the best overall.

This post concludes the Ghia Road Course series.

FJC