Syncro Transaxle

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Syncro Transaxle

Since this forum is slow, here's a link to a Syncro trans thread:

http://www.thesamba.com/vw/forum/viewto ... le+service

http://www.thesamba.com/vw/forum/viewto ... le+service

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- fusername

- Posts: 6806

- Joined: Sun Jan 28, 2007 11:26 am

Re: Syncro Transaxle

wow. further proof that when I open a trans to rebuild, I will have 0 idea what wear looks like. Ugh i hate not knowing. good stuff, bookmarked.

give a man a watch and he'll allways know what time it is. give him two and he can never be sure again.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

Things are rarely just crazy enough to work, but they're frequently just crazy enough to fail hilariously.

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Syncro Transaxle

Why didn't you loctite the pinion bearing nut? BTW your camera rocks!

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Syncro Transaxle

The harder Chromoly can present seizure issues that the soft OE nut never had. This is because the pinion bearing and aftermarket nut are close in Rockwell hardness.

I wished to convey my hesitancy to use Loctite (which can increase risk of thread seizure), while promoting an alternative (race-tested) method of securing the Chromoly lock ring.

The bonus is that this method allows using lubricating oil on the threads, rather than Loctite.

I also wished to point out the superiority of the Type II nut over the Type I nut .. a no-brainer in all Waterboxers.

I wished to convey my hesitancy to use Loctite (which can increase risk of thread seizure), while promoting an alternative (race-tested) method of securing the Chromoly lock ring.

The bonus is that this method allows using lubricating oil on the threads, rather than Loctite.

I also wished to point out the superiority of the Type II nut over the Type I nut .. a no-brainer in all Waterboxers.

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Syncro Transaxle

Makes sense... I haven't had trouble with loctite seizing on the threads, but it does make it a pain to get the nut off if the bearing starts spinning in the case. A stock T2 nut will hold a lot and I have seen very few actually pull the threads from pinion force.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Syncro Transaxle

It's normally off-road shockloading that causes the stock nut to expand and jump one thread. It doesn't take long to loosen further, allowing the pinion bearing to slop forward/rearward in its bore.

The stock nut in a Type II is the same as in a Type I .. thin and inadequate for some applications. The Chromoly version Type II is much thicker as it incorporates the washer .. and it has one or two more threads.

The stock nut in a Type II is the same as in a Type I .. thin and inadequate for some applications. The Chromoly version Type II is much thicker as it incorporates the washer .. and it has one or two more threads.

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- Henryhoehandle

- Moderator

- Posts: 764

- Joined: Wed Jan 22, 2003 12:01 am

Re: Syncro Transaxle

The chromoly one with the washer is the one I use for hp use.

-

Bruce2

- Posts: 7097

- Joined: Sat Oct 13, 2001 1:01 am

Re: Syncro Transaxle

That's why I never use loctite on the nut.Henryhoehandle wrote:.... it does make it a pain to get the nut off if the bearing starts spinning in the case.

I find many cores I pull apart have a loose nut. But that same loose nut was staked by the factory. My conclusion is that the width of the bearing support part of the case got pounded over time.

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Syncro Transaxle

Here's the latest installment on Syncro transaxle upgrades, from sister forum:

http://www.thesamba.com/vw/forum/viewtopic.php?t=568039

http://www.thesamba.com/vw/forum/viewtopic.php?t=568039

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86

- Pablo2

- Posts: 408

- Joined: Sat Jun 25, 2011 5:37 pm

Re: Syncro Transaxle

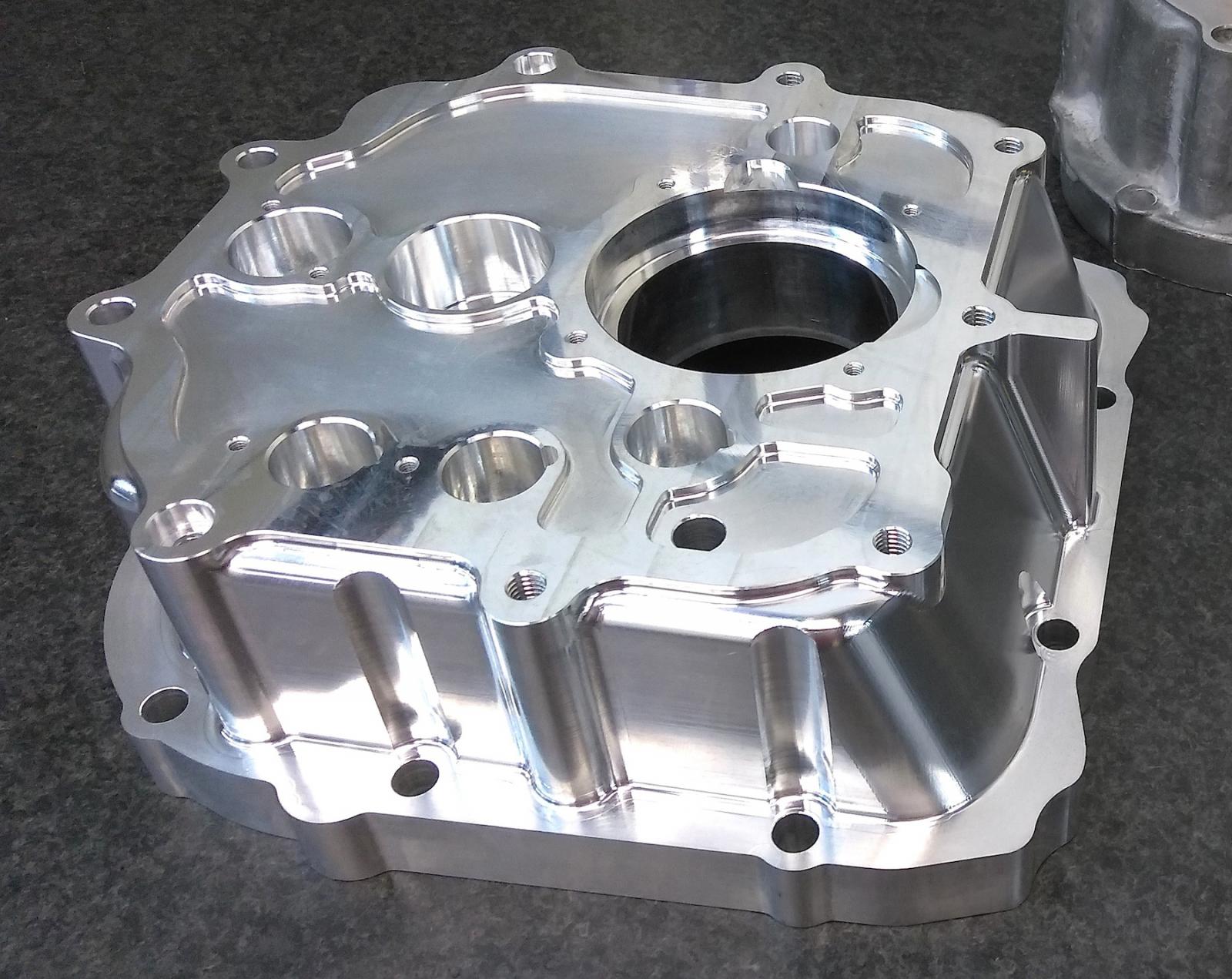

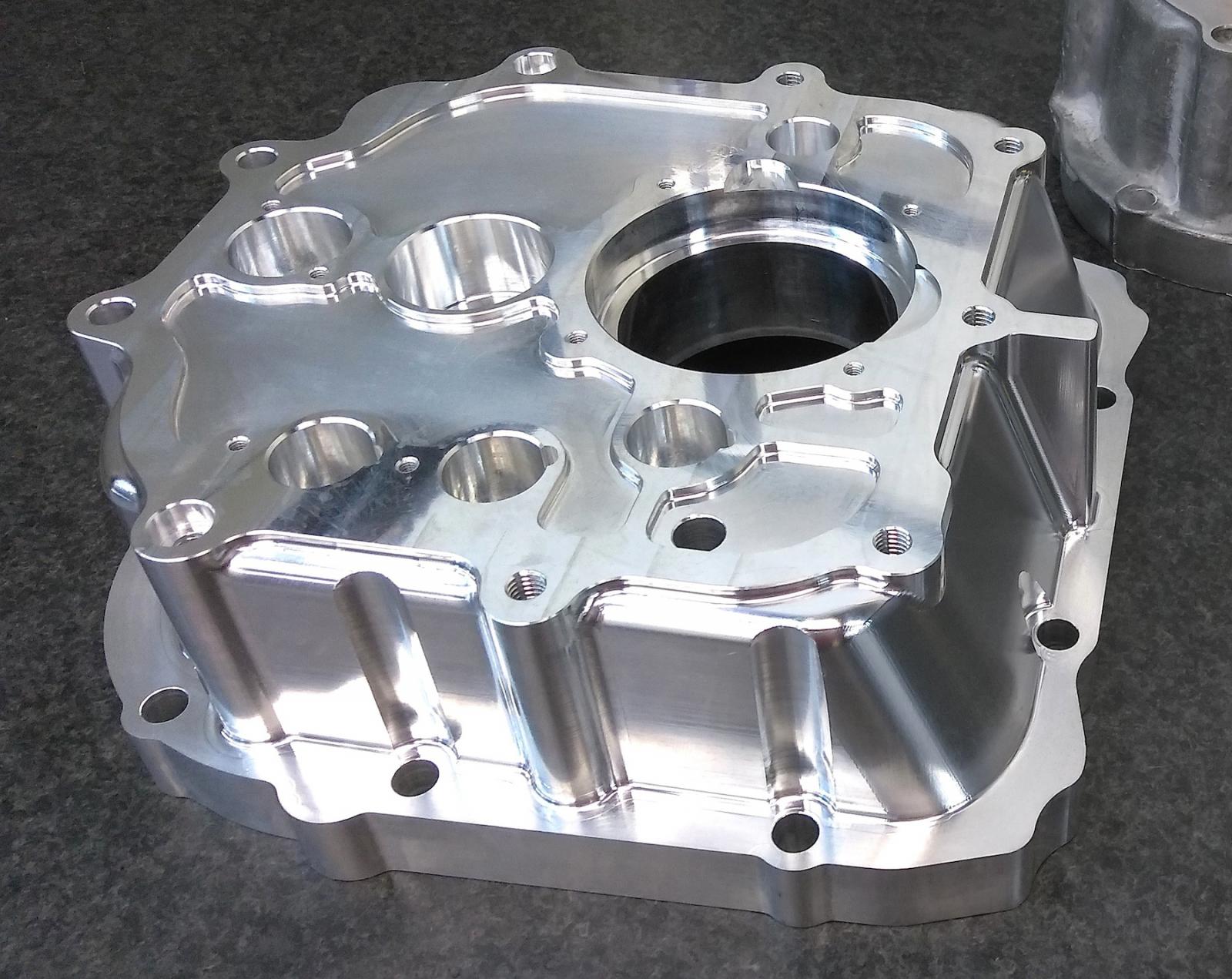

I thought I'd update this thread, showing the parts we're now offering to build the ultimate-strength Syncro 4WD Vanagon transaxle ..

Gears with F1 tooth profiles (German steel, ultra-deep heat treatment):

Gun-drilled mainshafts supply oiling to all needle bearings (note replaceable 2nd gear synchro teeth):

Besides greatly increased strength & longevity, this new carrier offers integral splash plates/dams and a secondary thrust bearing for the pinion:

Gears with F1 tooth profiles (German steel, ultra-deep heat treatment):

Gun-drilled mainshafts supply oiling to all needle bearings (note replaceable 2nd gear synchro teeth):

Besides greatly increased strength & longevity, this new carrier offers integral splash plates/dams and a secondary thrust bearing for the pinion:

aka Pablo, gears, Geary

9.36 @ 146 in '86

9.36 @ 146 in '86