Custom a-arm suspension

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Custom a-arm suspension

I'm just starting my Subaru ej205 swap and wanted to look into what it would take to switch to custom a-arms in the rear.

At this point it would really help if a few kind souls could hook me up with some measurements off the stock rear suspension as I dont have any stock rear trailing arms.. I'm trying to find the rear axle center line as measured from the rear door jam to the center of the rear wheel at ride height. If anyone could pull me a quick measurement that would be much appreciated!

P.S. Body is a standard 70' bug (IRS)

At this point it would really help if a few kind souls could hook me up with some measurements off the stock rear suspension as I dont have any stock rear trailing arms.. I'm trying to find the rear axle center line as measured from the rear door jam to the center of the rear wheel at ride height. If anyone could pull me a quick measurement that would be much appreciated!

P.S. Body is a standard 70' bug (IRS)

- ONEBADBUG

- Posts: 213

- Joined: Wed Dec 02, 2009 9:25 pm

Re: Custom a-arm suspension

It doesn't matter. If you are going to build A-Arms, you can put the wheelbase anywhere as long as the tires don't hit the fenders. The drive axles can go forward or back from stock. Because your engine weighs more, you would want to move the wheels as far back as possible.

-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Custom a-arm suspension

I pretty much agree with this. Going from two pivot points to a single pivot point allows you to fit the location to the wheel well. The same with axle and arm length but I think you also have to deal with the CVs, the wheels and rim size plus accoutoments such as the brakes. The design of the A-arms also add to make this an interesting phenomon you are playing.ONEBADBUG wrote: ↑Mon Feb 25, 2019 11:46 am It doesn't matter. If you are going to build A-Arms, you can put the wheelbase anywhere as long as the tires don't hit the fenders. The drive axles can go forward or back from stock. Because your engine weighs more, you would want to move the wheels as far back as possible.

It'll be an interesting design problem you will be playing with; I am looking forward to follow the build.

Lee

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

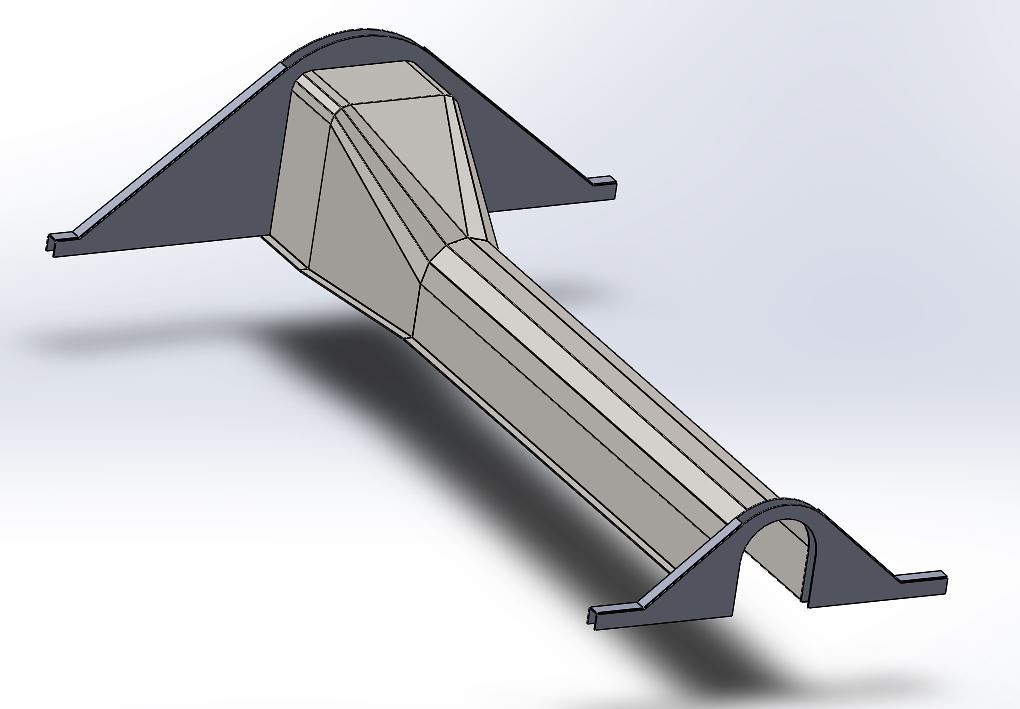

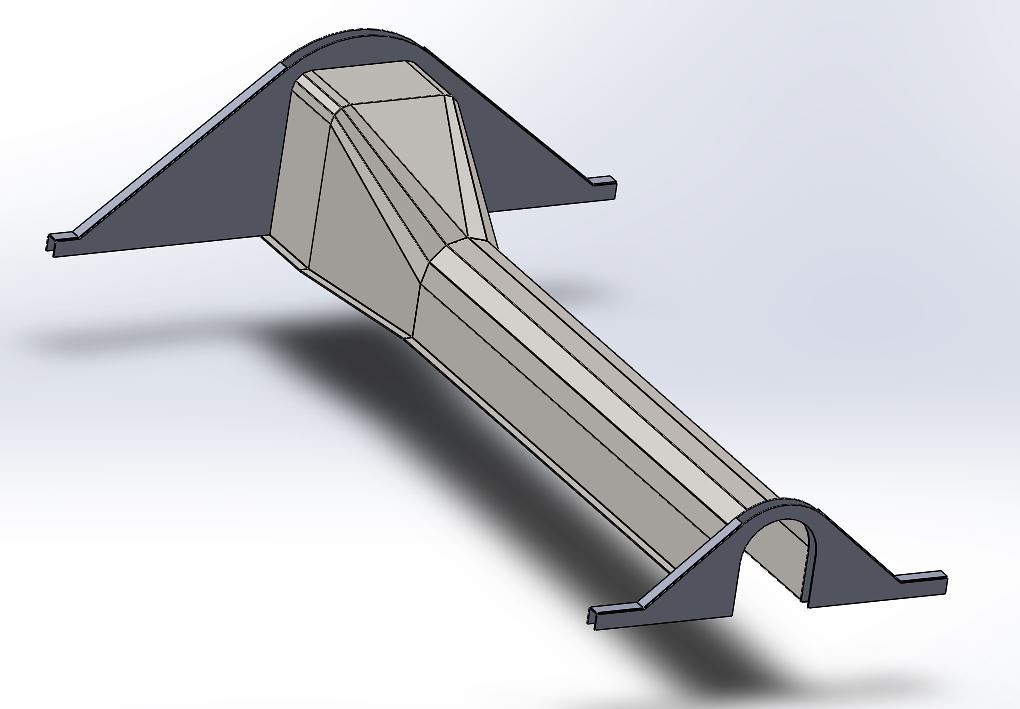

so here is my design for the trans tunnel that now needs to house a driveshaft.

Capture2 by , on Flickr

Capture2 by , on Flickr

get her bent up and test fit

IMG_20190411_123156 by , on Flickr

IMG_20190411_123156 by , on Flickr

here's the rear suspension desgin

Capture1 by , on Flickr

Capture1 by , on Flickr

and here's the engine and trans hanging in the rear with a few of the frame tubes. Still need to make some control arms

IMG_20190411_123124 by , on Flickr

IMG_20190411_123124 by , on Flickr

IMG_20190411_123109 by , on Flickr

IMG_20190411_123109 by , on Flickr

Capture2 by , on Flickr

Capture2 by , on Flickrget her bent up and test fit

IMG_20190411_123156 by , on Flickr

IMG_20190411_123156 by , on Flickrhere's the rear suspension desgin

Capture1 by , on Flickr

Capture1 by , on Flickrand here's the engine and trans hanging in the rear with a few of the frame tubes. Still need to make some control arms

IMG_20190411_123124 by , on Flickr

IMG_20190411_123124 by , on Flickr IMG_20190411_123109 by , on Flickr

IMG_20190411_123109 by , on Flickr-

Ol'fogasaurus

- Posts: 17881

- Joined: Mon Nov 13, 2006 10:17 pm

Re: Custom a-arm suspension

Its sure is good to have 3D CAD/CAM isn't it. Just imagine how we used to do that (in 2D) on the drawing board. I filled up many 132" long (~11 feet) by 1m (high) Mylar (in ink or plastic lead) or linen by pencil drawing forms.

You guys sure have it easy now days!

Lee

You guys sure have it easy now days!

Lee

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

i've definitely had to do a little bit of manual CAD but nothing to crazy and idolize how anything was ever built to spec with out the help of computers lol!

Here's a bit more progress on the rear frame horns;

setting up to weld the nuts to the backside of the laser cut washers that weld to the end of the frame tubes

IMG_20190411_193017 by , on Flickr

IMG_20190411_193017 by , on Flickr

welded M20 nuts inside the frame horn ends just like the OG Vw

IMG_20190411_195615 by , on Flickr

IMG_20190411_195615 by , on Flickr

Here's a bit more progress on the rear frame horns;

setting up to weld the nuts to the backside of the laser cut washers that weld to the end of the frame tubes

IMG_20190411_193017 by , on Flickr

IMG_20190411_193017 by , on Flickrwelded M20 nuts inside the frame horn ends just like the OG Vw

IMG_20190411_195615 by , on Flickr

IMG_20190411_195615 by , on Flickr- panel

- Posts: 4210

- Joined: Sun Sep 24, 2000 12:01 am

Re: Custom a-arm suspension

Is the driveshaft tunnel for AWD ?

'65 Bus with a JDM Subaru EJ20 Turbo

Built by Germans powered by Japanese and brought together by Canadians

Built by Germans powered by Japanese and brought together by Canadians

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

the tunnel will house a driveshaft down the line. the trans is out of a 2015 WRX. So it's the cable shifted 6 speed which is why it's such a giant.

I bent up the trans mounting bracket

IMG_20190412_145250 by , on Flickr

IMG_20190412_145250 by , on Flickr

here's how it looks in place. It will be welded in place. notice the slot in the center of the bracket so the studs wont have to come up so high when installing the trans.

IMG_20190412_150336 by , on Flickr

IMG_20190412_150336 by , on Flickr

Also a pro tip for fabrication of any sort. These oem style jacks that almost all cars have are super clutch for mocking up parts as the have a fine thread and are disposable enough that you can weld all sorts of bracket types to the upper foot to help out with specific jobs. and can be had for $5 a piece at a junk yard

I bent up the trans mounting bracket

IMG_20190412_145250 by , on Flickr

IMG_20190412_145250 by , on Flickrhere's how it looks in place. It will be welded in place. notice the slot in the center of the bracket so the studs wont have to come up so high when installing the trans.

IMG_20190412_150336 by , on Flickr

IMG_20190412_150336 by , on FlickrAlso a pro tip for fabrication of any sort. These oem style jacks that almost all cars have are super clutch for mocking up parts as the have a fine thread and are disposable enough that you can weld all sorts of bracket types to the upper foot to help out with specific jobs. and can be had for $5 a piece at a junk yard

Last edited by vw1970 on Sun Apr 14, 2019 8:29 pm, edited 1 time in total.

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

today I mocked up and hand cut the bits for the bolt on engine mount cross member that mimics that oem VW style of frame horn termination. I needed to have this bit removable for ease of install. mainly to prevent the front differential bulge from fouling on the cross member. a combination of TIG and MIG because I was feeling lazy before lunch haha. It's not totally complete but is a working prototype for now.

IMG_20190414_212019 by , on Flickr

IMG_20190414_212019 by , on Flickr

IMG_20190414_212026 by , on Flickr

IMG_20190414_212026 by , on Flickr

IMG_20190414_212019 by , on Flickr

IMG_20190414_212019 by , on Flickr IMG_20190414_212026 by , on Flickr

IMG_20190414_212026 by , on Flickr-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

Welded up the laser cut parts from sendcutsend.com that i bent up yesterday and everything fit perfectly! Still needs to be finish welded with the MIG but i wanted to get good penetration so i dont have to weld to much of the back side.

IMG_20190416_133300 by Travis L, on Flickr

IMG_20190416_133300 by Travis L, on Flickr

IMG_20190416_133227 by Travis L, on Flickr

IMG_20190416_133227 by Travis L, on Flickr

IMG_20190416_133300 by Travis L, on Flickr

IMG_20190416_133300 by Travis L, on Flickr IMG_20190416_133227 by Travis L, on Flickr

IMG_20190416_133227 by Travis L, on Flickr- panel

- Posts: 4210

- Joined: Sun Sep 24, 2000 12:01 am

Re: Custom a-arm suspension

Gorgeous parts !

'65 Bus with a JDM Subaru EJ20 Turbo

Built by Germans powered by Japanese and brought together by Canadians

Built by Germans powered by Japanese and brought together by Canadians

- dlamyle

- Posts: 153

- Joined: Tue Jul 09, 2013 11:27 am

Re: Custom a-arm suspension

Seriously, you're not allowed to post anymore pictures of your welds. How am I supposed to look my kids in the eyes anymore.

1968 Karmann Ghia, JDM EJ205, Subarugears, OBX LSD, Blouch 16g XTR, Killer B Headers, DW 750cc, Meth Inj, Cobb AP w/Mach V 22psi Dyno tune (332whp)

Videos

Build Thread

Videos

Build Thread

- itawolf

- Posts: 295

- Joined: Thu Sep 02, 2010 6:07 pm

Re: Custom a-arm suspension

wow very good work

RET Marine 0317 --with VW on the lobe!!

Lots of iron in the fire

Lots of iron in the fire

-

vw1970

- Posts: 169

- Joined: Sat Aug 27, 2011 4:18 pm

Re: Custom a-arm suspension

Thanks for all the praise everyone!!

next time I'll include a short disclaimer before I post weld porn as to not have anyone else disowning their children lol

I'm a welder by trade and take pride in my welds more than most welders you might meet. I also work at a small fabrication/machining job shop so it enables me to have access to a lot of equipment without the large company profitability/insurance hustle so I'm kind of cheating hahaha.

In the last few days I've obtained some sweet seat through a little Craigslist fuckery. Finally finding the coolest miata club member that needed a good excuse to upgrade to some aftermarket track seats.. To my benefit!

Just blocked up the seats to roughly oem seat base height and they fit wonderfully. I've seen a few on threads of people putting these in vw based buggies and as an aftermarket upgrade to the oem seat in type1's. I have to say they fit so well i'm glad the other seat options ended up falling through. These were had for $400 for the set in 9/10 condition.

IMG_20190421_191838 by Travis L, on Flickr

IMG_20190421_191838 by Travis L, on Flickr

Also I got around to tacking together a control arm jig for the uppers in the rear. used a chunk of .25" hot rolled for the base because it was cheap. I made my own adjustable camber links out of a couple full thread grade 8 1"-14 4" long bolts. I had the machinist notch the hex end portion to fit against the bushing sleeve after i turned the hex off on the lathe and attempted to hole saw notch the sleeve profile in the head unsuccessfully. Only burnt up two hole saws on the mill after getting half way through one bolt head and work hardening it.. Need to do some bending and notching but I'll get to that later next week.

IMG_20190421_191714 by Travis L, on Flickr

IMG_20190421_191714 by Travis L, on Flickr

next time I'll include a short disclaimer before I post weld porn as to not have anyone else disowning their children lol

I'm a welder by trade and take pride in my welds more than most welders you might meet. I also work at a small fabrication/machining job shop so it enables me to have access to a lot of equipment without the large company profitability/insurance hustle so I'm kind of cheating hahaha.

In the last few days I've obtained some sweet seat through a little Craigslist fuckery. Finally finding the coolest miata club member that needed a good excuse to upgrade to some aftermarket track seats.. To my benefit!

Just blocked up the seats to roughly oem seat base height and they fit wonderfully. I've seen a few on threads of people putting these in vw based buggies and as an aftermarket upgrade to the oem seat in type1's. I have to say they fit so well i'm glad the other seat options ended up falling through. These were had for $400 for the set in 9/10 condition.

IMG_20190421_191838 by Travis L, on Flickr

IMG_20190421_191838 by Travis L, on FlickrAlso I got around to tacking together a control arm jig for the uppers in the rear. used a chunk of .25" hot rolled for the base because it was cheap. I made my own adjustable camber links out of a couple full thread grade 8 1"-14 4" long bolts. I had the machinist notch the hex end portion to fit against the bushing sleeve after i turned the hex off on the lathe and attempted to hole saw notch the sleeve profile in the head unsuccessfully. Only burnt up two hole saws on the mill after getting half way through one bolt head and work hardening it.. Need to do some bending and notching but I'll get to that later next week.

IMG_20190421_191714 by Travis L, on Flickr

IMG_20190421_191714 by Travis L, on Flickr