I'm helping a buddy build an engine for his 66 bus.

Design Criteria:

1. Budget friendly but ok to spend dollars where it makes sense.

2. Be visually interesting. Something you just do NOT see in a bus engine compartment.

3. Be able to move around a slammed 66 bus running IRS rear suspension.

4. Good drivability and street manners.

My buddy found a CHEAP, non-running, but complete 1800 from a Porsche 914, but no intake (has 40mm webers). It was absolutely caked in grease and dirt and had probably overheated a good bit when it had last run. But it had ALL the tins and such.

We pulled it down and sent the heads to EMW for a full freshen up. Turned out one was cracked in the exhaust port and wasn't worth fixing. The EMW folks found a good core and got the pair of heads freshened up with all new stainless valves and heavy duty springs and hardware.

We had planned on using the original pistons and cylinders but they were crap so a set of 96mm slip-ins were ordered.

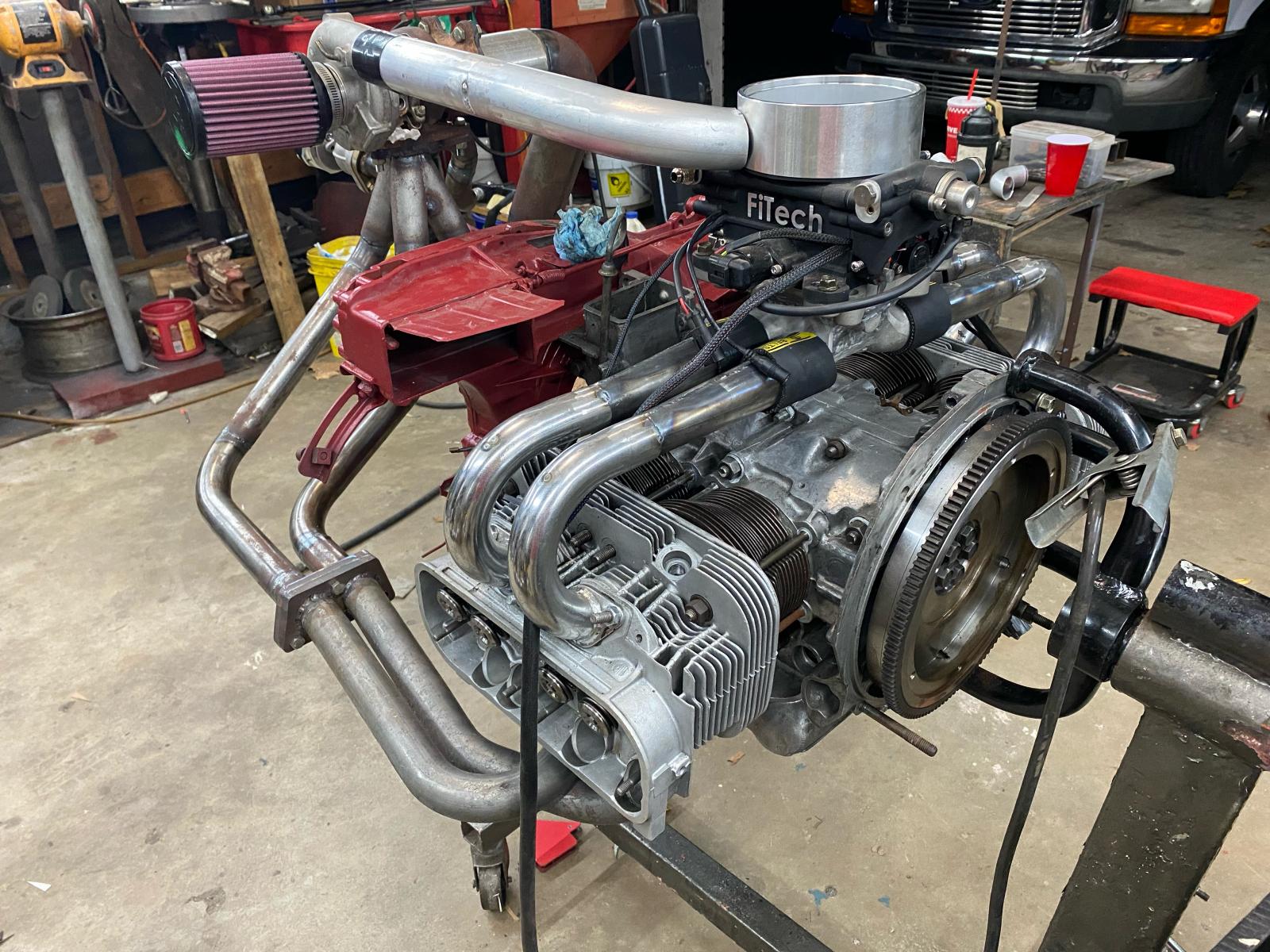

Crank and rods are stock 1800 and flywheel is a 200mm conversion flywheel from EMW.

Cam is a CB performance 2202 "Street Power" with matching lifters donated by a buddy who's into Type 4 upright engines.

Exhaust system is built from EMW 1-1/2" heater box replacements but with thicker flanges installed. The rest of the header was built using mandrel bends and collector I had lying around the shop. All flanges were cut on our CrossFire-Pro CNC plasma table.

Induction started with a highly modified progressive intake. It's had a larger 4 barrel flange welded on and extensive welding and shaping done to it. It's probably going to get more before we're done. Runners were enlarged where the meet the cast aluminum plenum. Instead of slipping INSIDE the casting they now butt-up flush. Then along the length they tapper down as they flow to the intake valves. This will allow porting inside the plenum for much improved airflow.

Topping off the manifold is a FiTech 600 EFI unit. This is actually a normally aspirated however we will be loading "Power Adder" software to it to do what we need. Feeding the Fitech is a TD04 turbo from a very crashed Subaru WRX, courtesy of my cousin. This turbo will be well sized for throttle response and make plenty of power. I don't see us running more than 10-12 lbs boost.

The idea is for the header and turbo to be just kinda 'in your face' like so many turbo bugs and bajas do. In this config there will be no engine lid obviously. Interestingly enough, we WILL be installing side scoops onto the sides of the bus. The logic is to bring as much fresh air to the engine compartment as possible (logically) even though there is no rear lid. The idea is to have as much free air as a baja bug. If the engine shows signs of running warm or hot, then we'll resort to header wrap or possible some other thermal management options.

I think I will use this topic to cover the long block build, cooling tins and such. I think for the turbo specific items, fabrication and tuning, I will open a separate topic in the Forced Induction Forum.