Have a real question/conundrum,

And figured why not do like we always useta and ask on the STF?

Still some of you guys around, right?

So, I'm doing a Bus motor for a friend,

And it turns out the core was an old Raby 'Powerstroke' from 2002 or so.

It was CIS, if that gives any idea of the vintage,..

Heads had been switched out on it, so if it's still the original configuration is anyone's guess,

But,

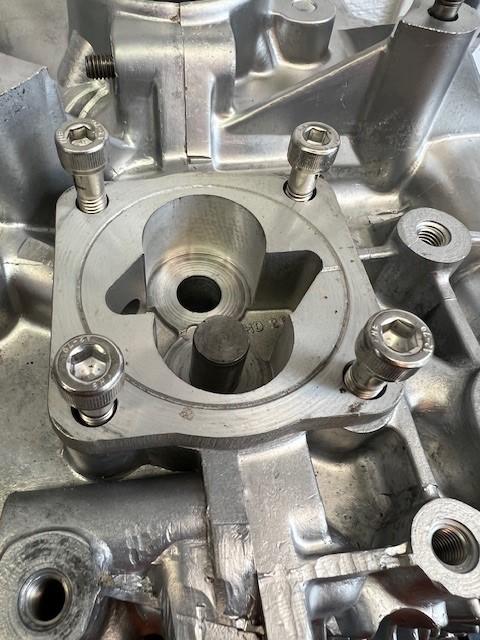

Check this out.

Had a 30mm Schadek oil pump in it,

But also, one of Jake's taller plungers with the angled groove -and- a shiny China pressure booster spring?

This might make sense, right?

If you put in a bigger pump,

You'll overwhelm the pressure relief and bypass the cooler otherwise, right?

Wonder if that was done intentionally by the man himself after careful deliberation and research?

Or was it some random dude who later rebuilt the thing?

Since the Schadek is smaller on the pump body OD,

I like to switch out the pump studs for bolts.

That way i can glue the pump in place and help stop leakage around the pump body.

As the case halves are joined, I'll 518 the bee hatch and smoosh it into place.

That'll stop leakage past the body, right?

Just gotta make sure to clean out the passages before it dries.

Because you aren't supposed to thread straight into the aluminum,

We insert the four pump studs, here using Keen-Serts.

Challenge is getting all of this flat, so the gasket gets good purchase, especially since we're not using one there.

Using shoulder bolts helps support and align things,

As well as helping seal there in the absence of sealing nuts.

All well and good, right?

That is, until the 30 pump goes back in.

Holes are NOT located accurately enough to clear the shoulder bolts we plan on using.

So now we have to find another pump. It took too much hogging to get the holes to work.

So, I immediately suspected my own work (of course),

But pulling a new 26 Schadek i got from Jake years ago and trying it on,

The holes lined up perfectly with no mods needed.

Same with a couple of covers i had.

So that got me to thinking...

I was always taught that bigger pumps were a hoax.'

My motors have all been smaller pump. Never a 30 ever anywhere.

Going to the type 4 store, all they sell now is the 30?

https://lnengineering.com/type-4-store/ ... ories.html

Now I'm starting to question all that i ever knew...

LN always only sold the good stuff.

Maybe LN just is over it and getting rid of old stock and out of type 4s like everyone else?

Check out the difference here:

30 on left, 26 in middle and 24 on right.

ALL type 4s, 914 2.0, Bus, anything... Always a 24mm pump, right??

The 26 is already a bit bigger.

Why always 30 for everyone?

Even Jake?

I dunno, man.. Going on the hunt for another pump, It's hard for me to buy a 30.

Have a few here because i always take them out.

A stroker Bus 2109, that might end up getting an oil cooler (against my advice)

Would you run a 30?

What are the chances the holes will be in the wrong place again?

If i had any more stock pumps in decent shape I'd use one of those with a stock spring.

If buying Brazil, it would be 26,

But now?

If anyone has anything to add, I'm all ears.

Thanks for listening to my rant.